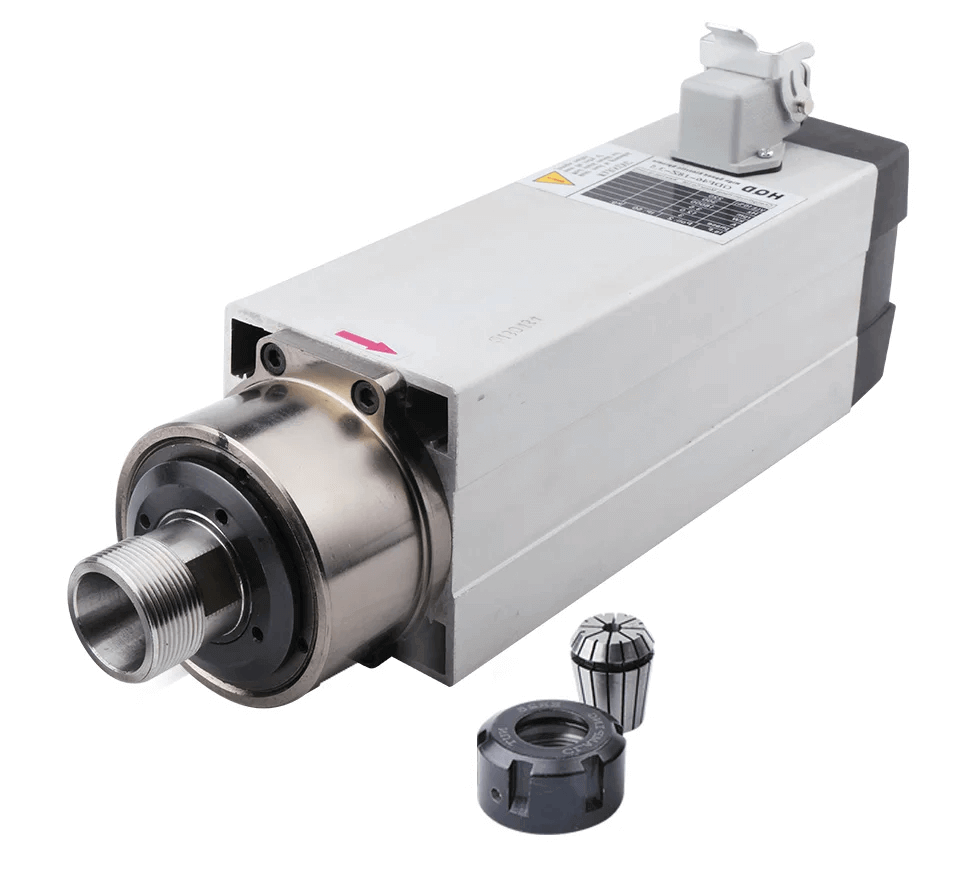

CNC 3.5KW 220V 380V Air Cooled Square Spindles Motor ER25

Description

CNC 3.5KW 220V 380V Air Cooled Square Spindles Motor ER25

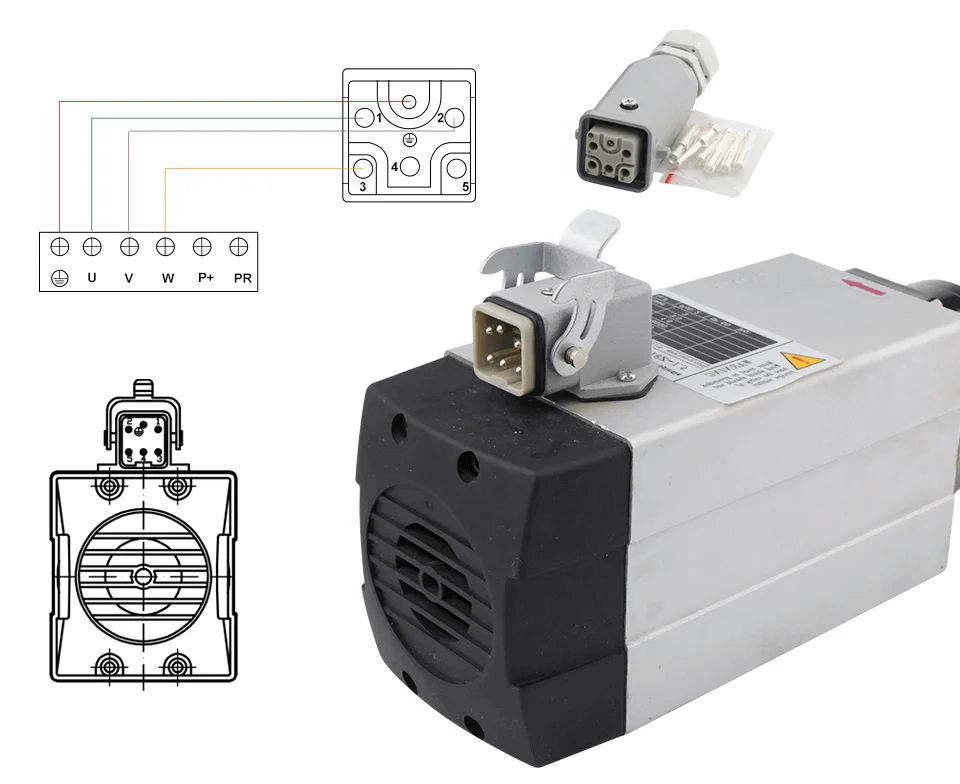

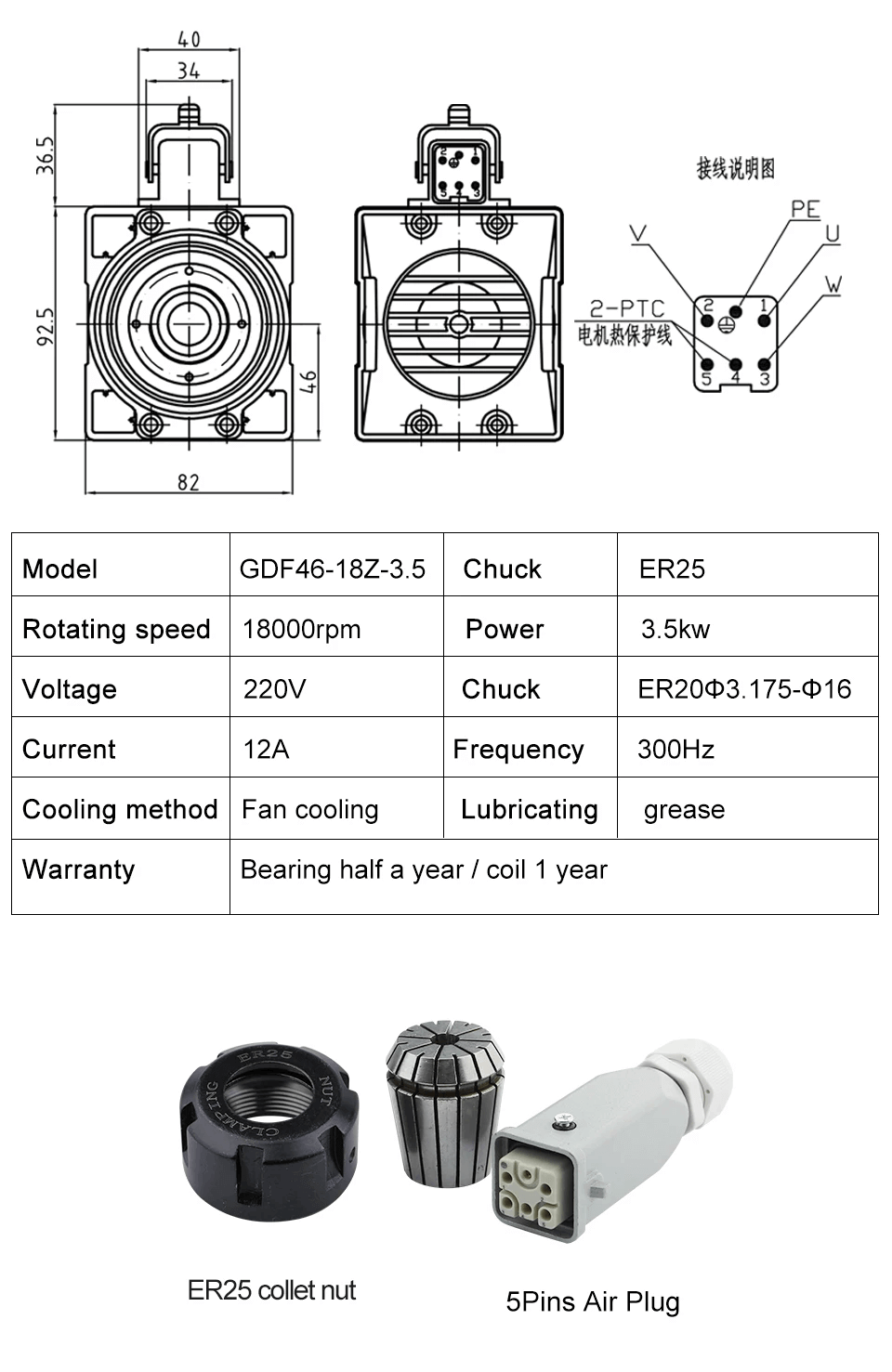

The CNC Spindle Basic Parameter

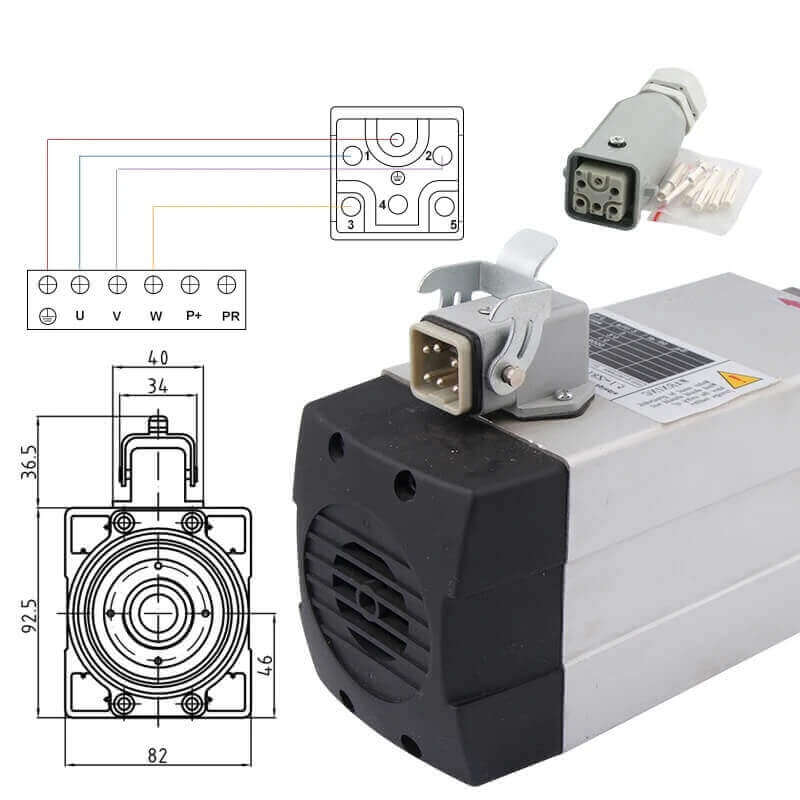

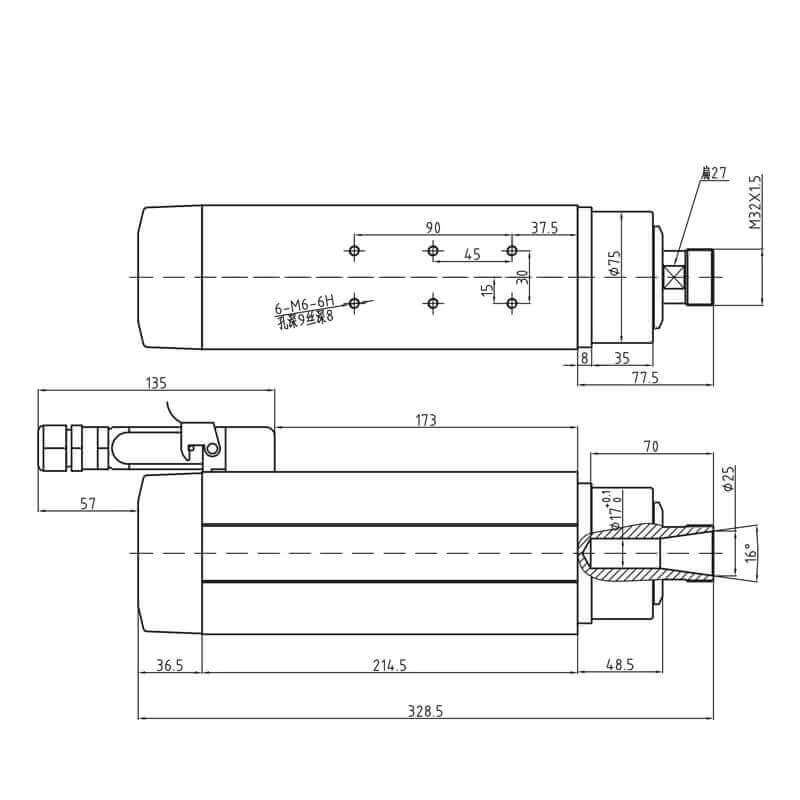

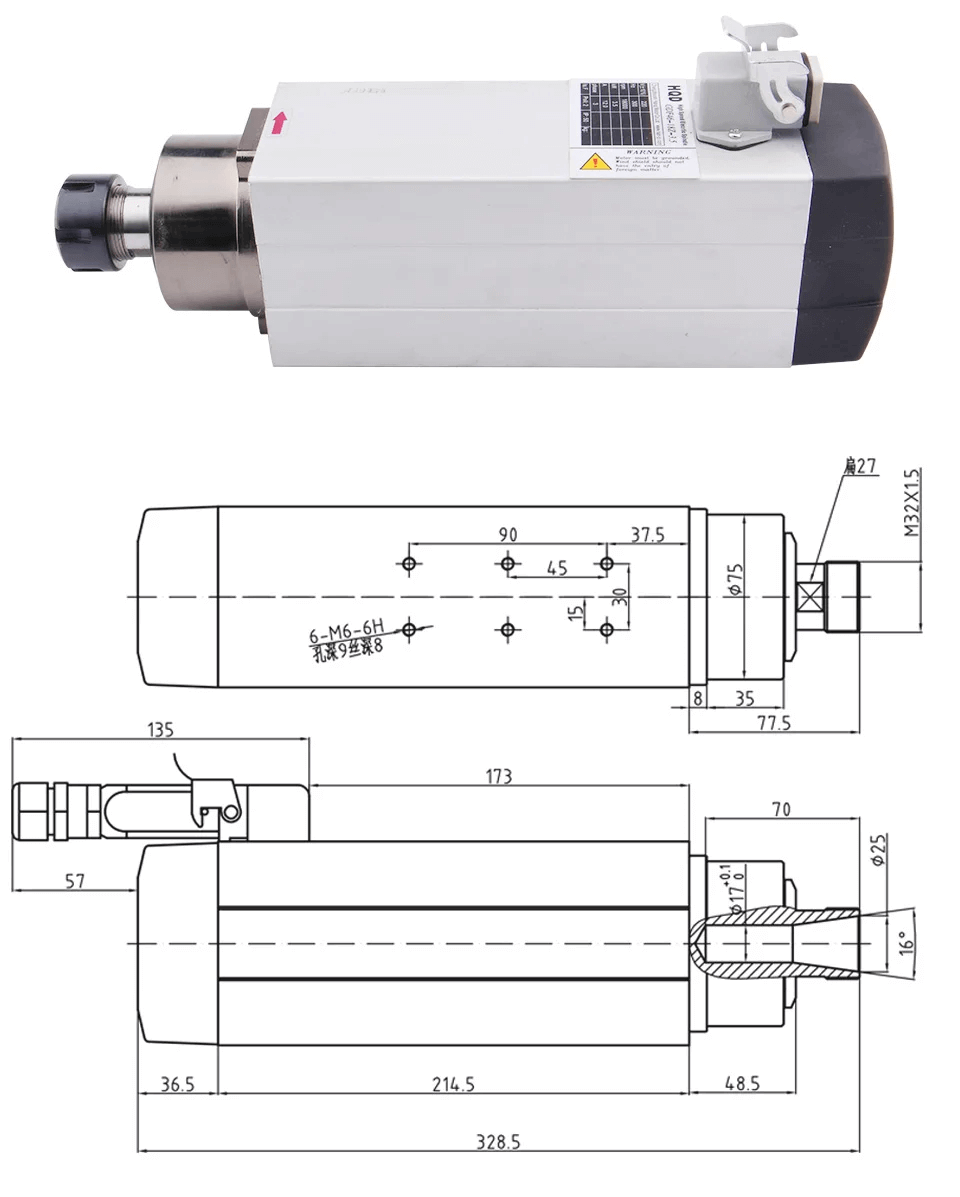

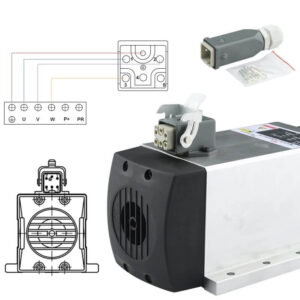

- Model: GDF46-18Z/3.5

- Power: 3.5KW

- Chuck: ER25

- Cooling: Air Cooled

- Rotating Speed: 18000rpm

- Electric Current: 12A

- Spindle Frequency: 300Hz

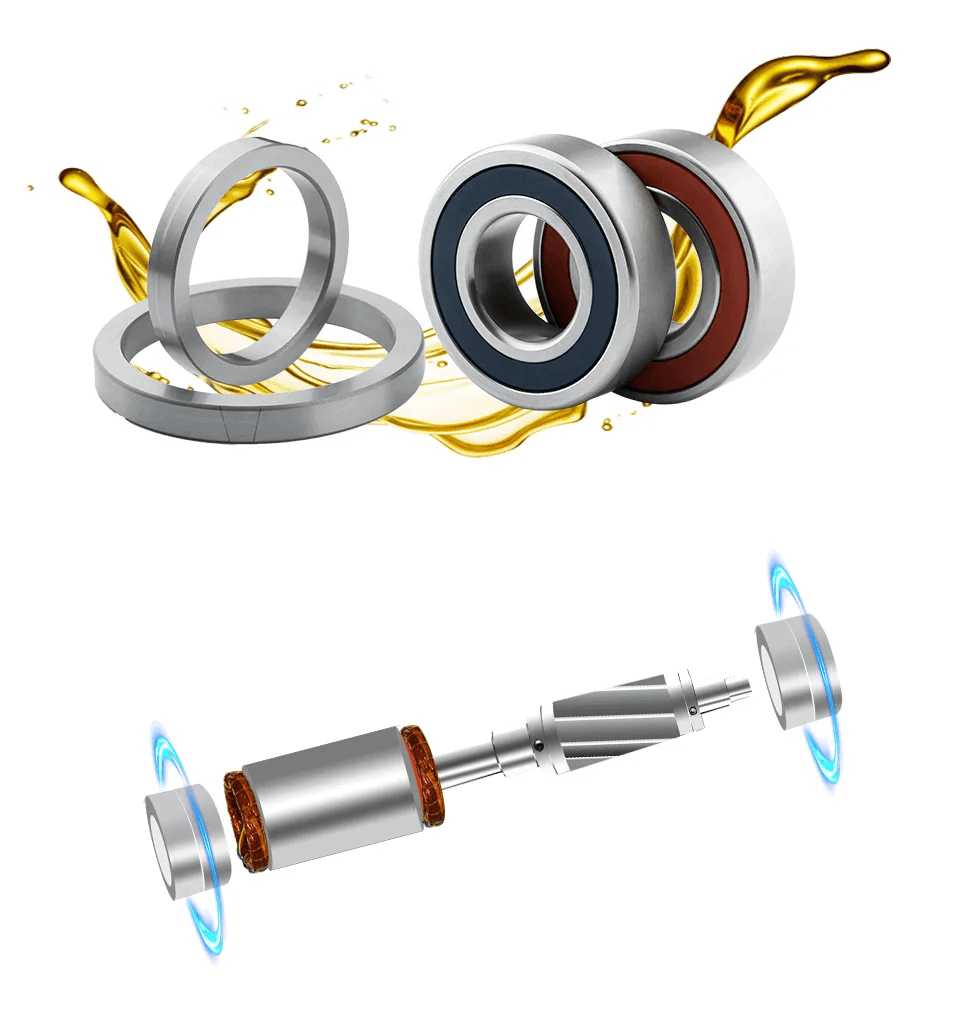

- Lubrication Method: Grease Lubrication

Overview of the CNC 3.5KW 220V 380V Air Cooled Square Spindles Motor ER25

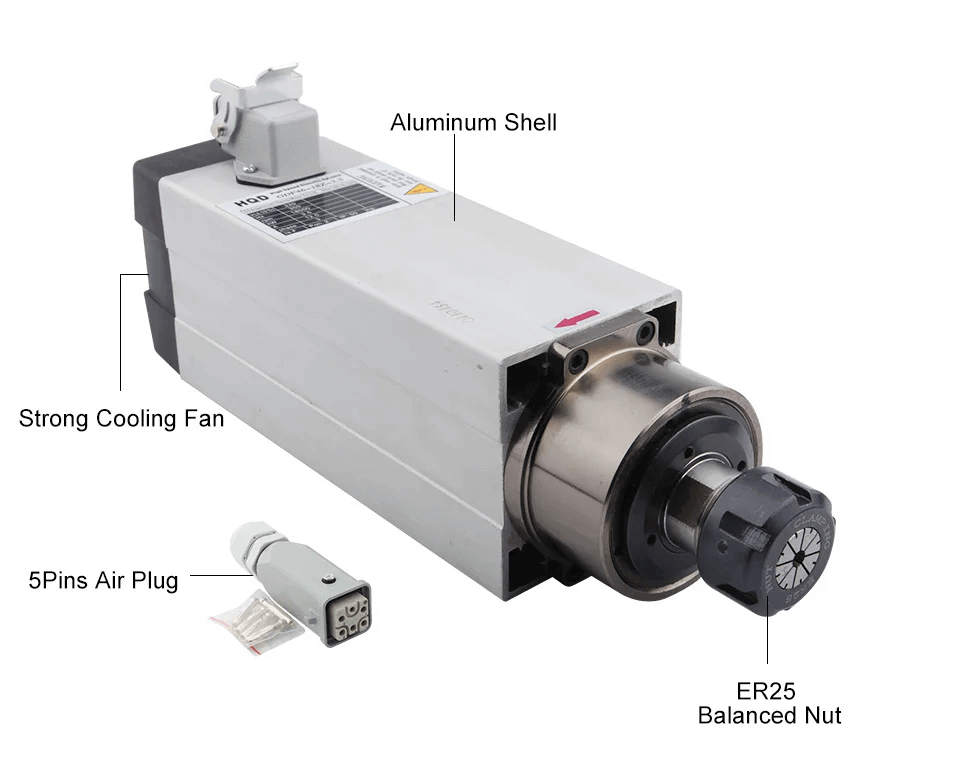

The CNC 3.5KW air-cooled spindle motor with ER25 collet is designed for high-performance machining across various industries. Here’s a detailed look at its features and applications:

Features of the CNC 3.5KW Air Cooled Spindle Motor

– Power and Voltage:Offers 3.5KW power output, compatible with both 220V and 380V electrical systems.

– Collet Type:ER25 collet, allowing flexibility in tool sizes for different machining tasks.

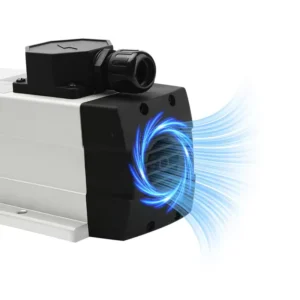

– Cooling System:Efficient air-cooled design for optimal heat dissipation and extended operational hours.

– Bearings:Equipped with high-quality bearings for smooth and stable performance.

– Mounting:Square spindle design ensures secure installation on CNC machines.

Applications of the CNC 3.5KW Air Cooled Spindle Motor

This spindle motor is versatile and suitable for a wide range of CNC applications, including:

– Woodworking:Ideal for cutting, carving, and shaping wood materials with precision.

– Metalworking:Suitable for machining aluminum, brass, and other non-ferrous metals.

– Plastics:Capable of handling various plastic materials like acrylic and polycarbonate.

– Composites:Efficient in cutting and milling fiberglass and carbon fiber composites.

– Prototyping:Essential for rapid prototyping and small-scale production tasks.

Industries Benefitting from the CNC 3.5KW Air Cooled Spindle Motor

Industries that benefit from this spindle motor include:

– Manufacturing:Enhances productivity in manufacturing processes requiring high precision and efficiency.

– Automotive:Used for machining parts, molds, and prototypes in the automotive sector.

– Aerospace:Provides precise machining capabilities for lightweight metals and composites used in aerospace applications.

– Furniture:Essential for creating intricate designs in wood and MDF for furniture production.

– Sign Making:Used in the signage industry for engraving and cutting various materials.

Materials Machined with the CNC 3.5KW Air Cooled Spindle Motor

Materials suitable for machining with this spindle motor include:

– Wood:Softwoods and hardwoods used in furniture making and carpentry.

– Metals:Aluminum, brass, and other non-ferrous metals used in manufacturing and prototyping.

– Plastics:Acrylic, polycarbonate, and other thermoplastics used in signage and manufacturing.

– Composites:Fiberglass, carbon fiber, and other composite materials used in aerospace and automotive industries.

In conclusion, the CNC 3.5KW 220V 380V Air Cooled Square Spindles Motor ER25 is a robust and versatile tool, suitable for various machining applications across different industries. Its powerful performance, combined with efficient cooling and reliable operation, makes it an essential component in modern CNC machinery.