Çin'in en büyük CNC Milleri Toptan Satış, Ahşap oymacılığı, metal frezeleme, taş oymacılığı vb. için her türlü cnc milini sunuyoruz. Dünyanın her yerine Hızlı teslimatla daha yüksek kalitede iş mili sunun.

CNC Makineleri için Hassas ve Verimli CNC Router Mil Motoru

Güvenilir bir mil, herhangi bir CNC yönlendiricinin kalbidir ve doğru CNC yönlendirici mil motoru, hassasiyet, dayanıklılık ve sorunsuz çalışmayı garanti eder.

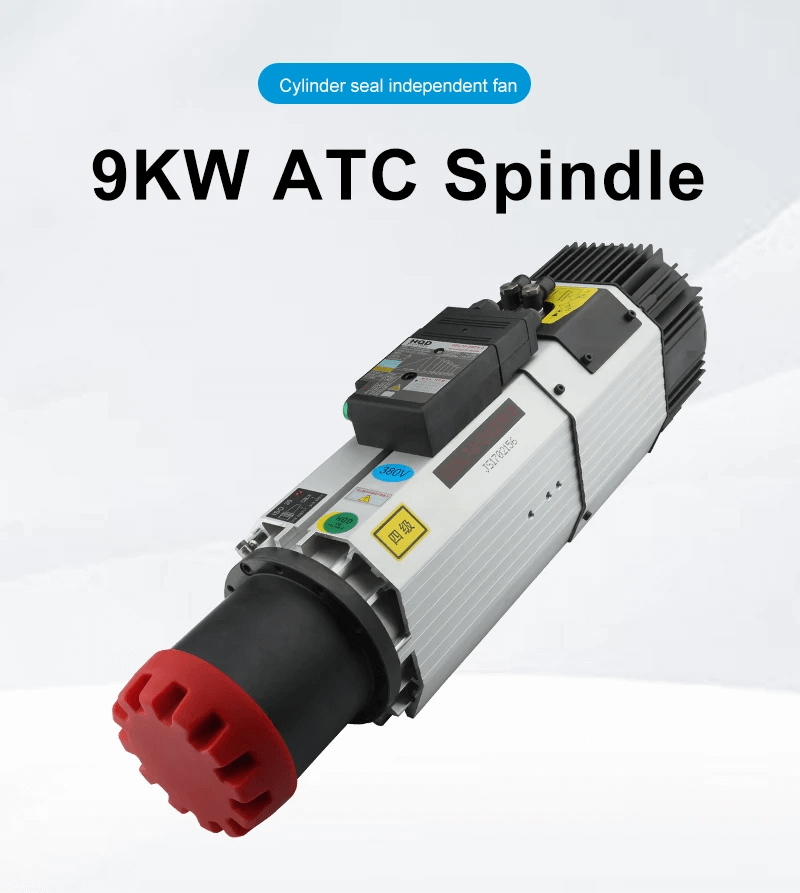

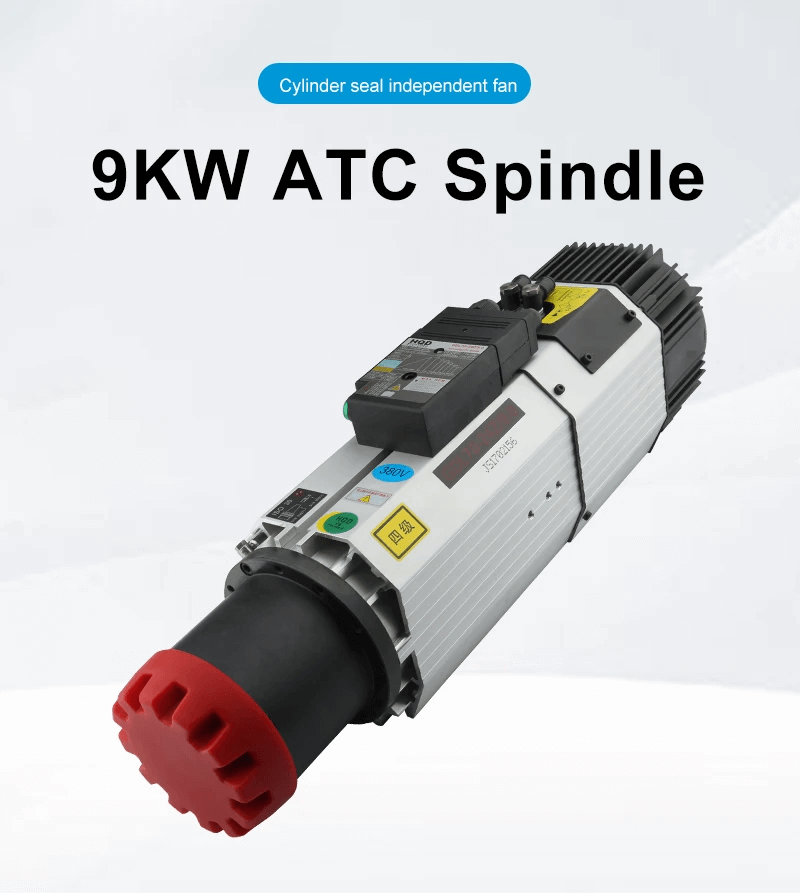

ATC Mil Motoru 9 kW – Yüksek Performanslı CNC Freze Mil Motoru

Güvenilir bir mil, herhangi bir CNC yönlendiricinin kalbidir ve ATC mil motoru HQD mil motoru serisi, ağaç işleme, metal işleme ve diğer endüstriyel uygulamalar için hassasiyet, dayanıklılık ve yüksek hızlı performans sunar.

Delme İçin Mil Motorları: 9 kW Hava Soğutmalı Yüksek Hızlı Çözüm

CNC işleme ve metal işleme dünyasında, verimlilik, doğruluk ve dayanıklılık açısından doğru mil motorunu seçmek çok önemlidir.

Hava Soğutmalı Mil Motorları: 9 kW Yüksek Hızlı CNC Router Mil Motoru

CNC işlemede, iş mili motoru makinenin kalbidir. Kesim işleminin kalitesini, hızını ve hassasiyetini belirler.

BT30 Mil Motoru, CNC Torna Mil Motoru ve ATC Mil Motoru

CNC işleme dünyasında, iş mili motoru, makinenin performansını, hassasiyetini ve güvenilirliğini belirleyen en kritik bileşenlerden biridir.

Router ATC Mil: Otomatik Takım Değiştirme ile CNC Router'ınızı Güçlendirin

CNC router yeteneklerini önemli ölçüde artıran bileşenlerden biri de ATC (Otomatik Takım Değiştirici) milidir.