Cel mai mare ax CNC din China, oferă tot felul de axuri CNC pentru sculptură în lemn, frezare metal, sculptură în piatră și așa mai departe. Oferiți ax de calitate superioară cu livrare rapidă în toată lumea.

Motor de ax pentru router CNC de precizie și eficiență pentru mașini CNC

Un ax fiabil este inima oricărui router CNC, iar motorul potrivit al axului routerului CNC asigură precizie, durabilitate și funcționare lină.

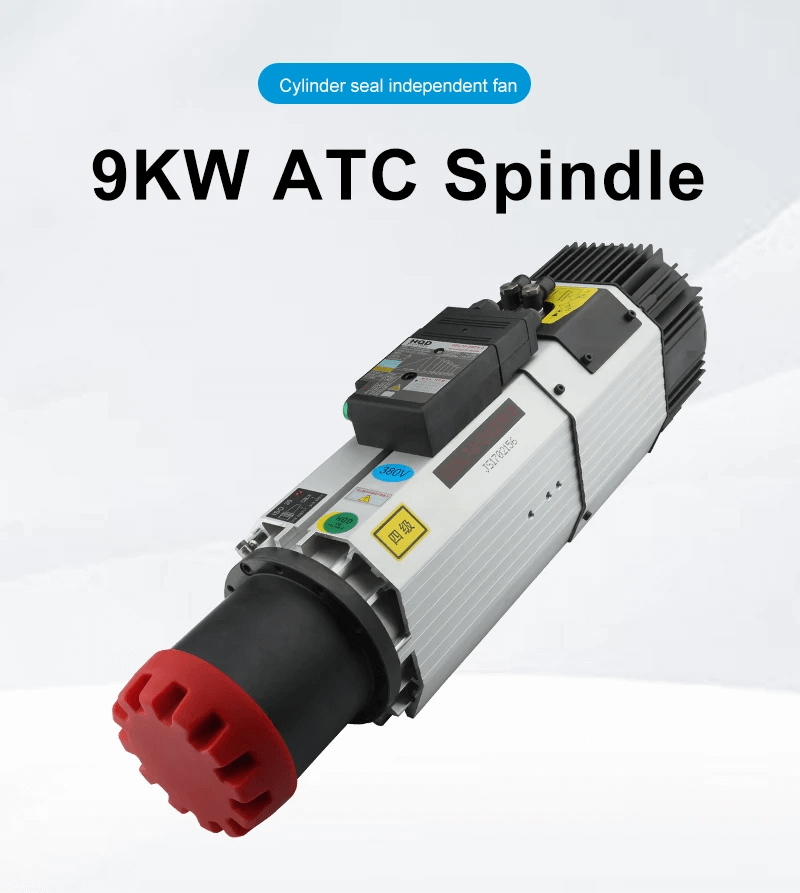

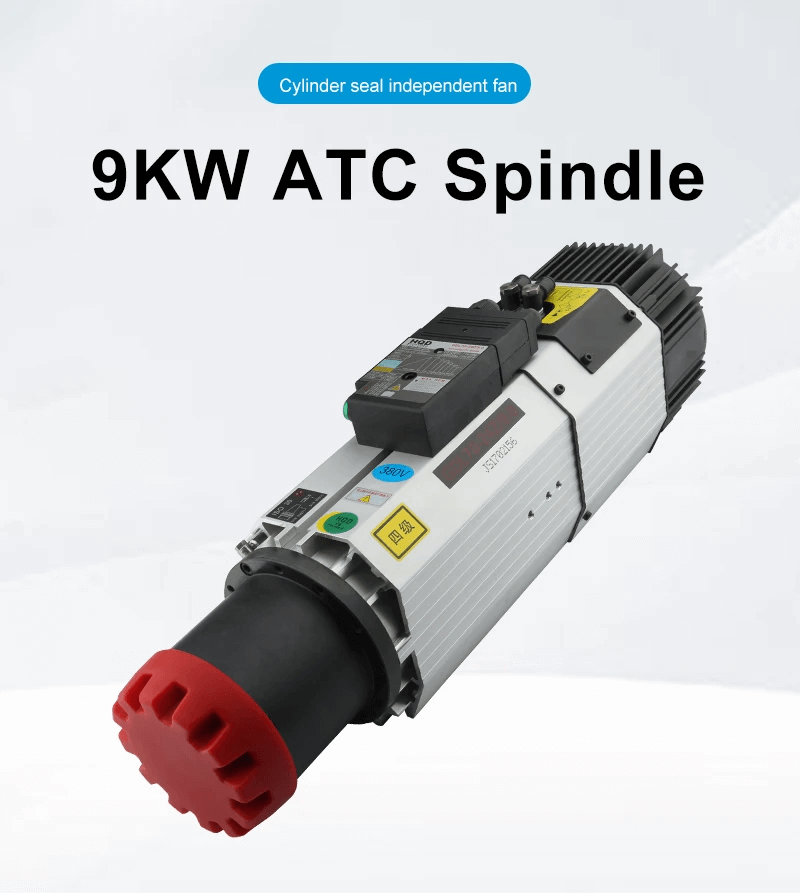

Motor arbore principal ATC 9 kW – Arborele principal de freză CNC de înaltă performanță

Un ax fiabil este inima oricărui router CNC, iar seria de motoare cu ax ATC HQD oferă precizie, durabilitate și performanță de mare viteză pentru prelucrarea lemnului, prelucrarea metalelor și alte aplicații industriale.

Motoare cu ax principal pentru găurire: Soluția de mare viteză răcită cu aer de 9 kW

În lumea prelucrării CNC și a metalelor, alegerea motorului potrivit pentru ax este crucială pentru eficiență, precizie și durabilitate.

Motoare cu ax răcite cu aer: Motorul cu ax al routerului CNC de mare viteză de 9 kW

În prelucrarea CNC, motorul axului este inima mașinii. Acesta determină calitatea, viteza și precizia procesului de așchiere.

Motor de ax BT30, motor de ax pentru strung CNC și motor de ax ATC

În lumea prelucrării CNC, motorul axului este una dintre cele mai importante componente care determină performanța, precizia și fiabilitatea mașinii.

Ax ATC pentru router: Îmbunătățiți-vă routerul CNC cu schimbarea automată a sculelor

O componentă care îmbunătățește dramatic capacitățile routerului CNC este axul ATC (schimbător automat de scule).