Os maiores fusos CNC da China no atacado, oferecem todos os tipos de fusos CNC para escultura em madeira, fresagem de metal, escultura em pedra e assim por diante. Ofereça fuso de maior qualidade com entrega rápida em todo o mundo.

Motor de fuso de roteador CNC de precisão e eficiência para máquinas CNC

Um eixo confiável é o coração de qualquer roteador CNC, e o motor de eixo correto garante precisão, durabilidade e operação suave.

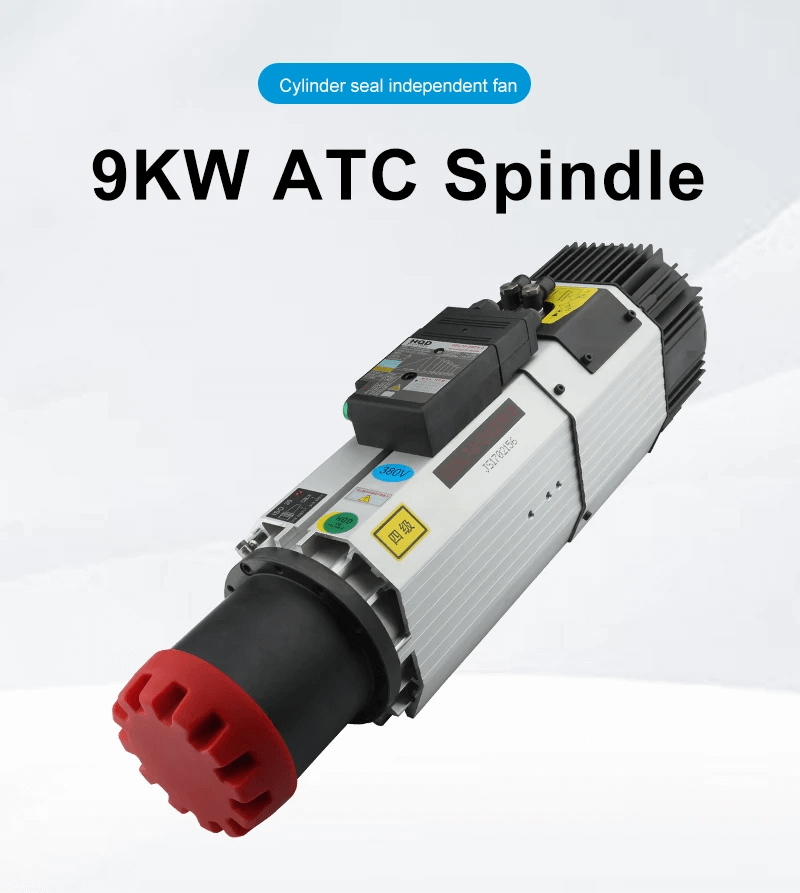

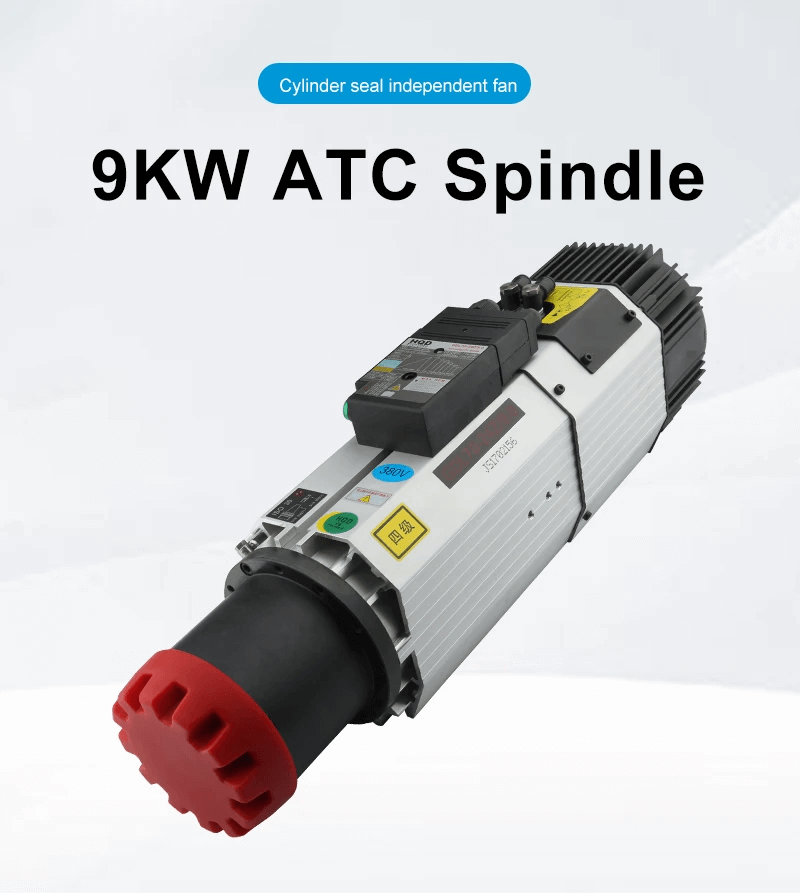

Motor de fuso ATC 9 kW – Fuso de roteador CNC de alto desempenho

Um eixo confiável é o coração de qualquer roteador CNC, e a série de motores de eixo ATC HQD oferece precisão, durabilidade e desempenho de alta velocidade para marcenaria, metalurgia e outras aplicações industriais.

Motores de fuso para perfuração: a solução de alta velocidade com refrigeração a ar de 9 kW

No mundo da usinagem CNC e metalurgia, selecionar o motor de fuso correto é crucial para eficiência, precisão e durabilidade.

Motores de fuso refrigerados a ar: Motor de fuso de roteador CNC de alta velocidade de 9 kW

Na usinagem CNC, o motor do fuso é o coração da máquina. Ele determina a qualidade, a velocidade e a precisão do processo de corte.

Motor de fuso BT30, motor de fuso de torno CNC e motor de fuso ATC

No mundo da usinagem CNC, o motor do fuso é um dos componentes mais críticos que determinam o desempenho, a precisão e a confiabilidade da máquina.

Fuso ATC para roteador: aprimore seu roteador CNC com troca automática de ferramentas

Um componente que melhora drasticamente as capacidades do roteador CNC é o fuso ATC (Trocador Automático de Ferramentas).