CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving

Description

CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving

Introduction

The CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving tool is a high-performance spindle designed for precision and efficiency in metal engraving and other demanding applications. With its robust power output and advanced cooling system, this spindle motor is perfect for professionals seeking reliable and accurate results. In this article, we will explore the features, parameters, applications, suitable materials, and industry areas for this versatile spindle motor.

Features of the CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving

High Power Output

The CNC Metal Spindles 1.2KW Water Cooled Spindle provides a powerful 1.2KW output, ensuring efficient material removal and precise cuts. Its high power capability enhances productivity and the quality of your metal engraving projects.

Advanced Water Cooling System

Equipped with an integrated water cooling system, this spindle motor maintains optimal operating temperatures, preventing overheating during extended use. This feature not only boosts performance but also extends the spindle motor’s lifespan, ensuring reliable operation under heavy workloads.

Precision and Stability

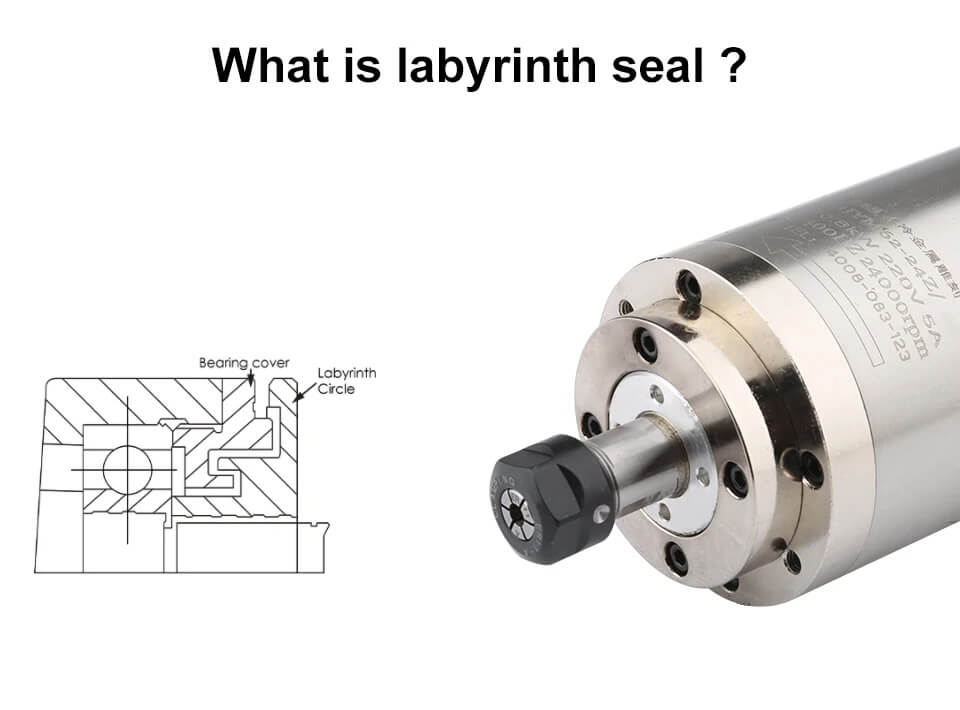

Featuring high-precision bearings, the CNC Metal Spindles 1.2KW Water Cooled Spindle offers superior stability and accuracy. The design ensures smooth and precise cuts, which are crucial for detailed metal engraving and milling projects where precision is essential.

Low Noise Operation

Compared to air-cooled alternatives, the water-cooled spindle operates at significantly lower noise levels. This feature is particularly beneficial for workshops where noise reduction is important, creating a more comfortable and efficient working environment.

Durability and Reliability

Constructed from high-quality materials, the CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving tool is built to withstand continuous use in demanding conditions. Its robust design reduces the need for frequent maintenance and ensures long-term reliability.

Key Parameters

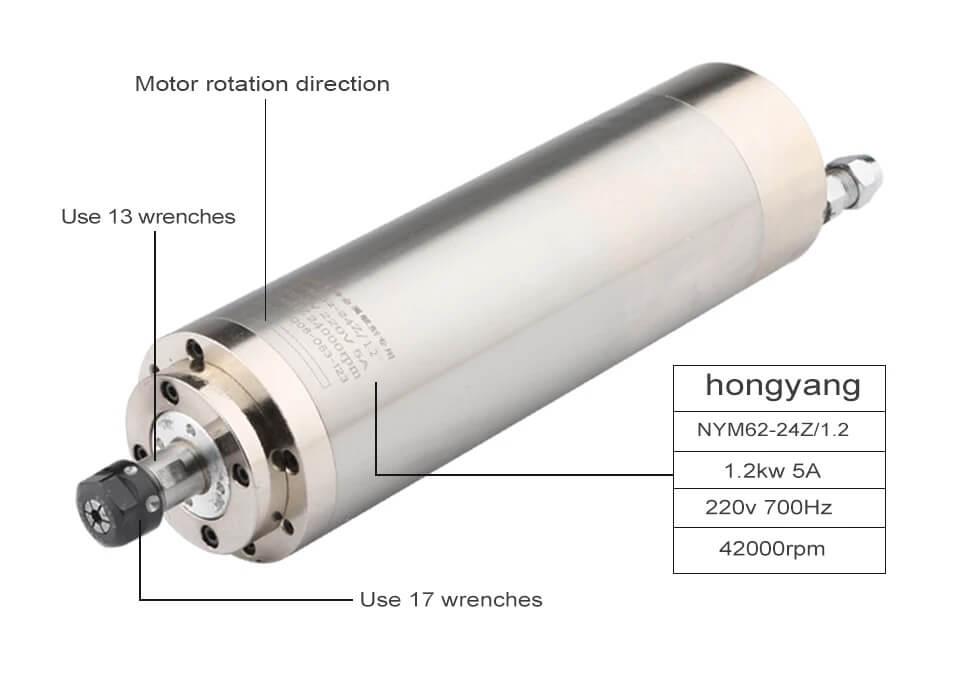

- Size: 62mm (diameter of the middle body: 62mm)

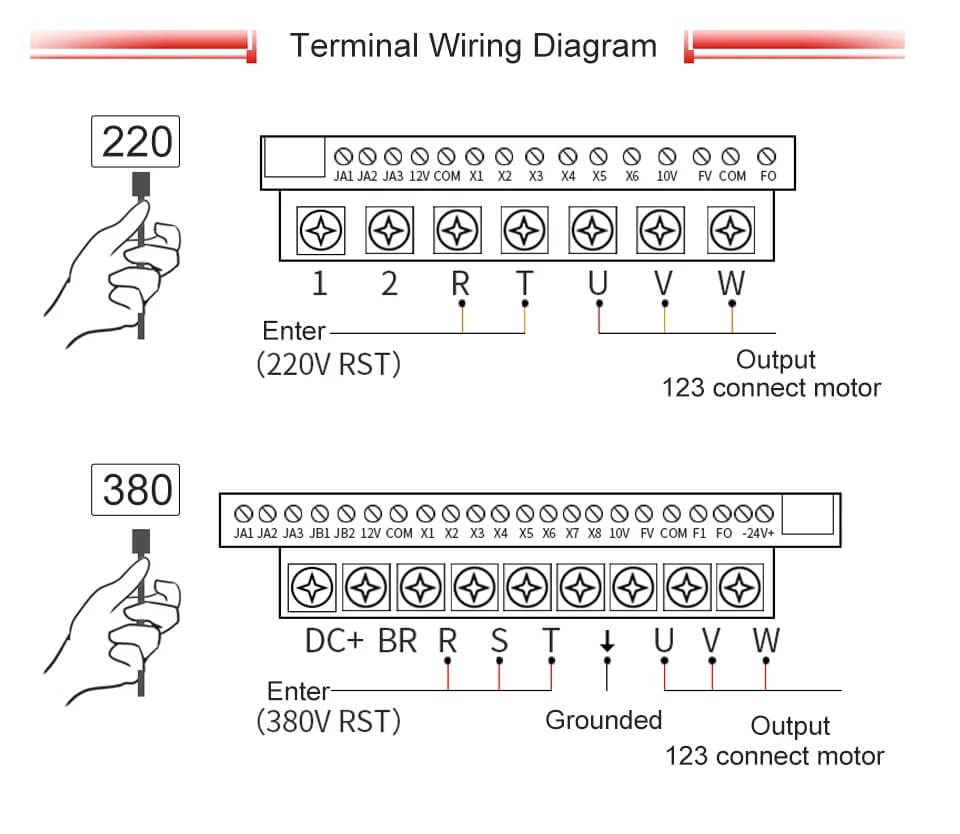

- Speed regulation mode: change the spindle speed through the three-phase output inverter and adjusting the frequency of the inverter.

- Cooling method: water cooling

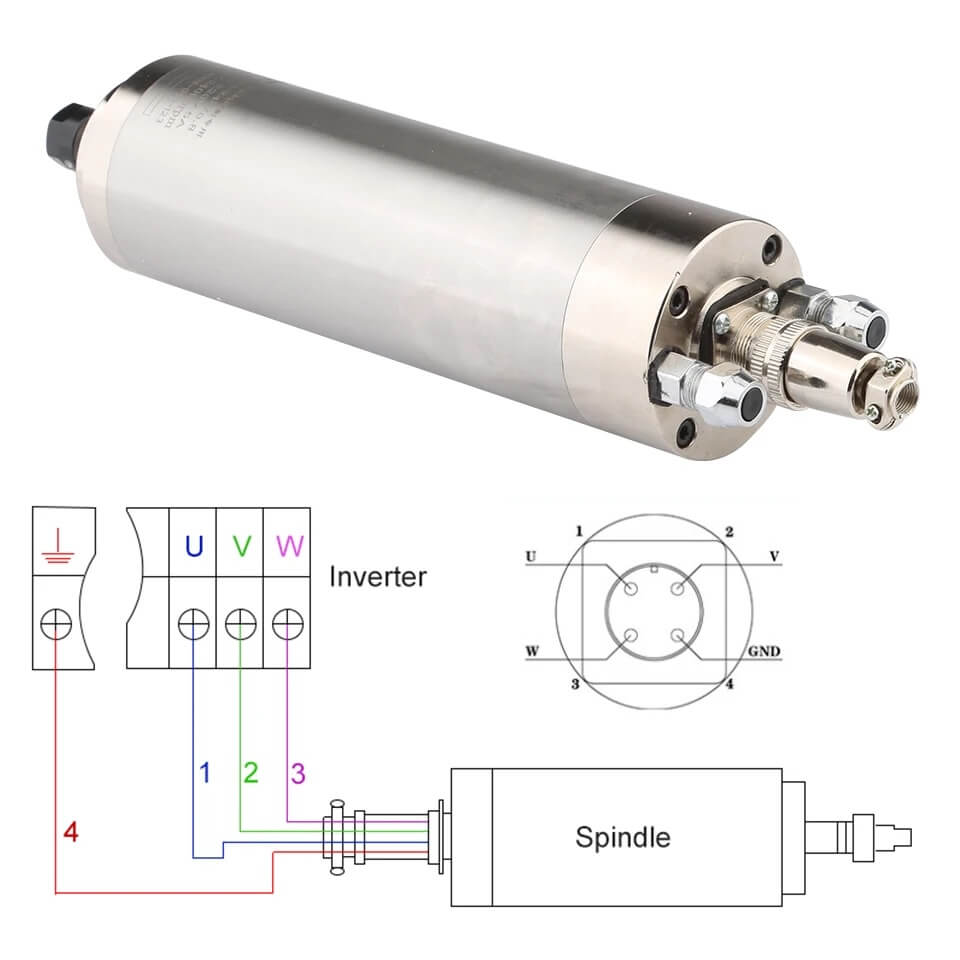

- Power interface: optional H17-4 pin waterproof aviation plug. Aviation plugs marked “1”, “2”, “3”, “4”, “1”, “2”, “3” are connected to the inverter (U, V, W), and 4 are connected to the inverter land.

- Power: 1.2kw

- Voltage: 220v

- Current: 5.0A

- Frequency: 700Hz

- Speed: 42000rpm

- Number of strokes: 2

- Jump close: less than 0.01mm

- Diameter (mm): 62

- 4pcs ceramic ball bearings (fully sealed angular contact bearings)

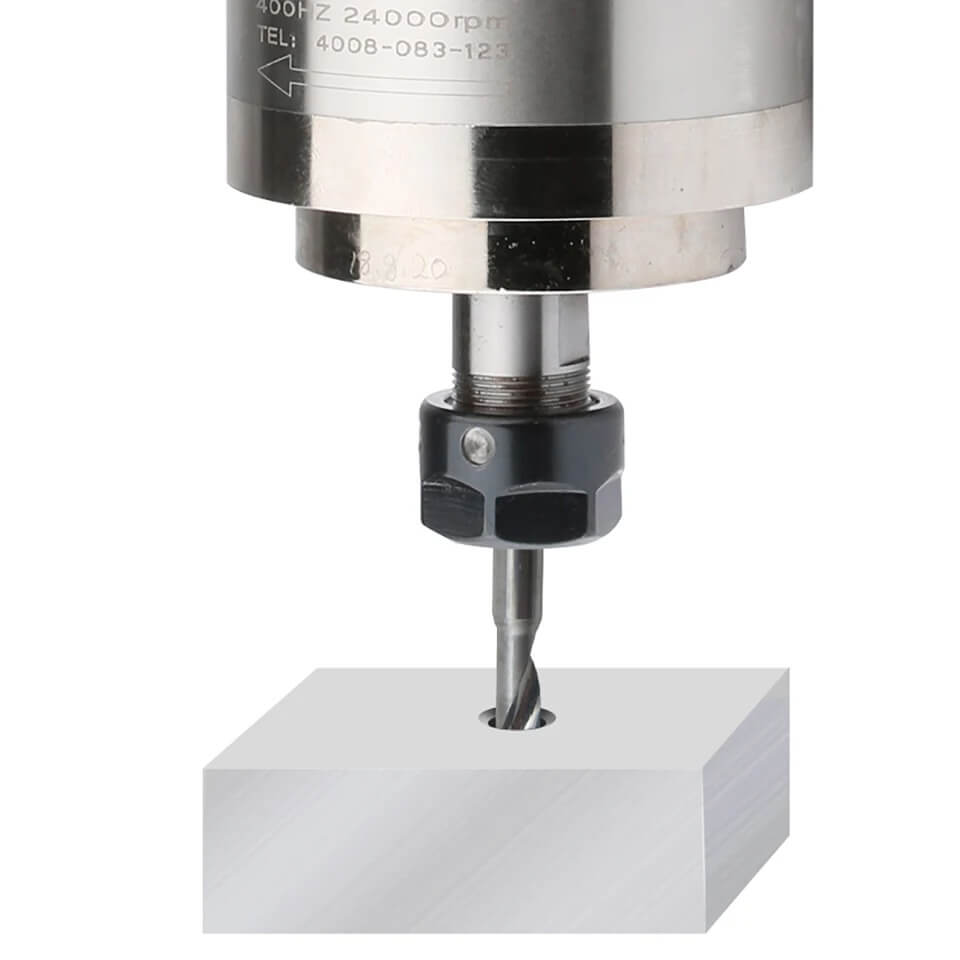

- Chuck: ER11

- Clamping tool diameter: 7mm, 6.5mm, 6.35mm, 6mm, 5.5mm, 5mm, 4.5mm, 4mm, 3.5mm 3.175mm, 3.0mm, 2.5mm, 2mm, 1.5mm, 1mm (standard 4mm)

- Water-cooled ER11 chuck block

- Grease lubrication

- Main application: carving iron, steel, stainless steel, aluminum, hardwood, etc. (this is a professional metal spindle with high precision and large torque)

Applications of the CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving

Metal Engraving

This spindle motor is perfect for a variety of metal engraving applications, including cutting, carving, and engraving intricate designs on various metals. Its high power and precision capabilities ensure efficient and accurate operations, making it a valuable tool for professional engravers.

CNC Milling

Beyond metal engraving, the CNC Metal Spindles 1.2KW Water Cooled Spindle is suitable for various milling applications. Its robust performance ensures precise cuts and efficient material removal, making it ideal for detailed milling projects.

Prototyping and Custom Fabrication

For prototyping and custom fabrication, this spindle motor offers the flexibility and accuracy needed to create prototypes and custom parts with ease. Its reliable performance ensures high-quality results in every project, making it ideal for both industrial and DIY applications.

Jewelry Making

In the jewelry-making industry, precision and detail are paramount. This spindle motor provides the necessary performance to create intricate and professional designs from various metals, ensuring high-quality results.

Suitable Materials for the CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving

- Metals: Aluminum, brass, copper, stainless steel, and other non-ferrous metals

- Plastics: Acrylic, PVC, ABS, polycarbonate

- Composites: Carbon fiber, fiberglass, laminates

Industry Areas Benefiting from the CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving

Metalworking Shops

In metalworking shops, precision and quality are essential. This spindle motor ensures accurate and detailed cuts, making it ideal for creating high-quality metal products and detailed engravings.

Jewelry Making

Jewelry making requires precise cutting and engraving capabilities. This spindle motor provides the necessary power and stability to create intricate designs from various metals, ensuring clear and detailed results.

CNC Machining Shops

CNC machining shops benefit greatly from the versatility and precision of this spindle motor. It can handle a variety of tasks, from intricate engravings to detailed milling, making it an invaluable tool for professional machinists.

DIY Enthusiasts and Hobbyists

DIY enthusiasts and hobbyists can also benefit from this spindle motor. Its user-friendly design and high performance make it suitable for a wide range of DIY projects, from crafting to home improvement, allowing users to achieve professional results at home.

Conclusion of CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving

The CNC Metal Spindles 1.2KW Water Cooled Spindle Engraving tool is a powerful and versatile spindle designed to meet the demands of high-precision metalworking and engraving tasks. Its efficient cooling system, precision bearings, and robust construction make it an invaluable asset in various industries. By understanding its features, parameters, applications, and suitable materials, you can maximize its potential and achieve exceptional results in your projects.