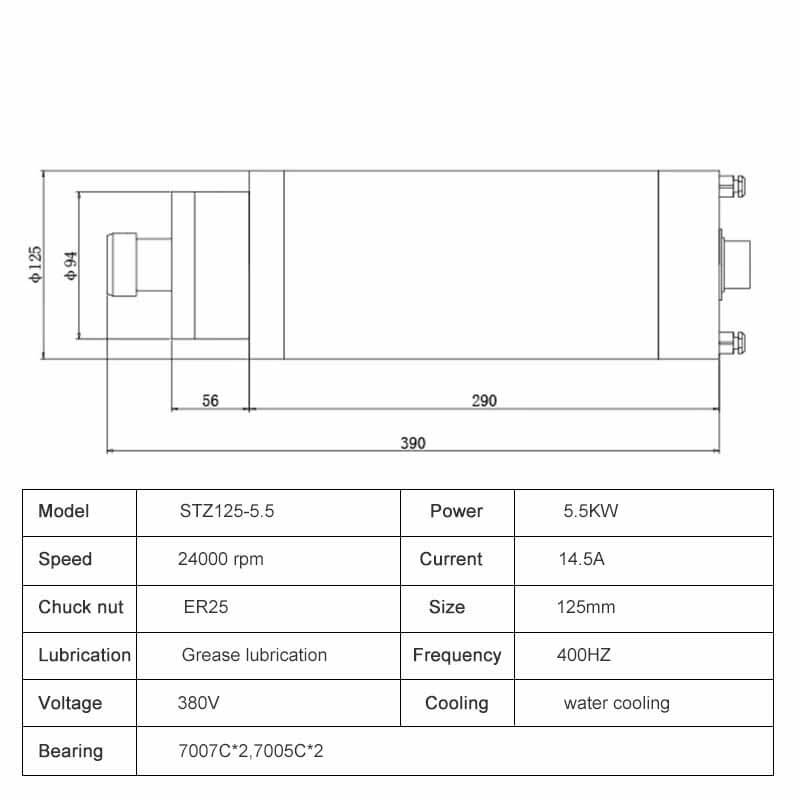

CNC 5.5KW ER25 Water-Cooled Spindle, 4 Bearings, 220V/380V

Description

CNC 5.5KW ER25 Water-Cooled Spindle, 4 Bearings, 220V/380V

- Middle body diameter: Φ125mm

- Speed regulation mode: change the spindle speed through the three-phase output inverter and adjust the frequency of the inverter.

- Cooling method: water cooling

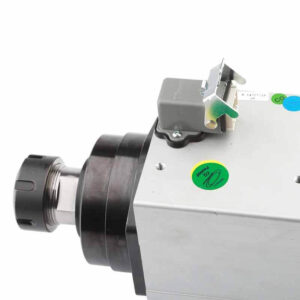

- Power interface: 4 pin waterproof aviation plug is optional. The aviation plugs marked “1”, “2”, “3”, “4”, “1”, “2”, “3” are connected to the inverter (U, V, W), and the 4 connected to the inverter will Ground the equipment.

- Power: 5.5kw

- Voltage: 220v 380v

- Current: 14.5A

- Frequency: 400Hz

- Speed: 24000rpm

- Bearing type: 7007C*2,7005C*2

- Chuck: ER25

- Grease lubrication

- Main purpose: used for wood, bamboo, ordinary PCB, PVC, PMMA, plastic, bamboo, two-color board (ABS) and other non-metallic carvings.

P4 Fully Sealed Angular Joint Bearings Extend Spindle Life

- Longer length provides greater torque and power.

- Precise assembly ensures higher spindle accuracy.

- Accuracy: 0.01mm, coaxial cable deviation: <0.0025mm.

Features:

- Equipped with 4 high-temperature resistant, low-heat bearings.

- Low friction and noise ball bearings for extended service life.

Instructions for Spindle Use and Maintenance

- Storage and Transport:

- During storage and transportation, the condition of the bearings in the high-speed grease may change. Before using the spindle, run it at a low speed for 30 minutes. Gradually increase the speed to 3000 rpm, running for 20 minutes at each step. Ensure the spindle and inverter are used together, with the inverter specifications and settings matching the spindle parameters.

- Inverter Connection:

- To connect the spindle to the inverter, solder the three-phase inverter power cord to pins 1 (U), 2 (V), and 3 (W), with pin 4 as the ground. After powering on, check the spindle rotation direction. If it is incorrect, immediately turn off the power and swap the two wires of the three-phase power supply connected to the inverter and spindle.

- Daily Start-Up:

- Before daily use, run the spindle at a low speed for 15-20 minutes. When clamping the cutter on the spindle, ensure the chuck nut, chuck, and cutter are thoroughly clean. The shank inserted into the chuck must be larger than 15mm.

Differences and Maintenance of Spindle Motors

- Cooling Methods:

- Water-Cooled Spindle: Uses water circulation to dissipate heat generated from high-speed rotation.

- Air-Cooled Spindle: Uses fan cooling to achieve the cooling effect.

- Noise:

- Water-Cooled Spindle: Operates with minimal noise.

- Air-Cooled Spindle: Generates significant noise due to the fan.

- Lifespan and Maintenance:

- Water-Cooled Spindle: Requires regular maintenance, including frequent water changes or using an industrial water cooler.

- Air-Cooled Spindle: Cools by blowing air over the heat sink, requiring less frequent maintenance.

- Material Use:

- For working with metal, hardwood, granite, or stone, a metal mandrel is recommended over a wooden one for better performance.

Operational Guidelines

- Frequency and Voltage:

- Connect the spindle frequency power supply to the rated voltage, ensuring the frequency matches the spindle’s technical parameters. Adjust spindle speed by changing the frequency, with voltage varying proportionally.

- Post-Use Maintenance:

- After use, blow out any remaining coolant in the pipeline with compressed air to prevent rust. Plug the water hole and oil the spindle. Use an anti-wave device and store in a dry place.

- Bearing Replacement:

- Bearing replacement should be done by professionals using special tools. Clean bearings thoroughly without removing the stator coil.