ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer

Description

ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer

In the highly competitive world of CNC machining, the ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer stands out as an exceptional solution for boosting efficiency, precision, and productivity. This article explores the key features, benefits, and applications of this powerful spindle, demonstrating why it is a preferred choice for professionals in various industries.

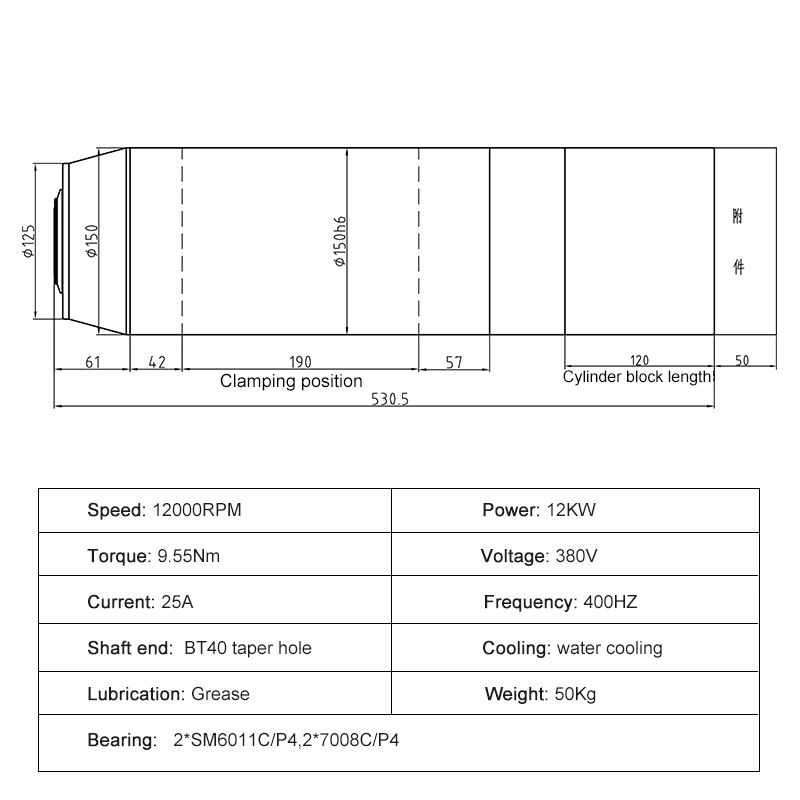

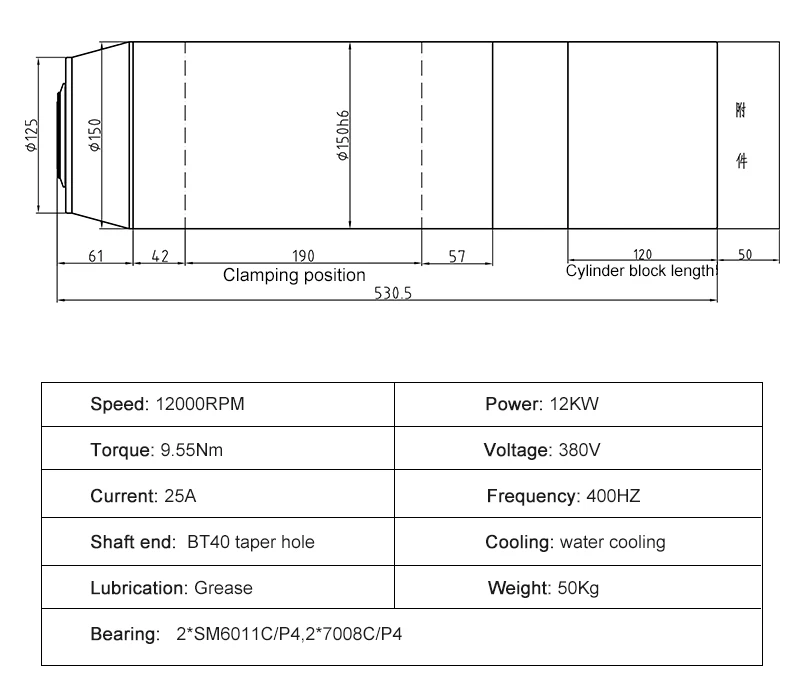

The specification of the ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer

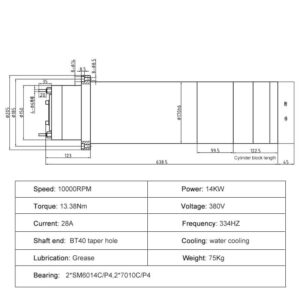

- Model: GDL150-40-12Z/12

- Diameter (mm): 150

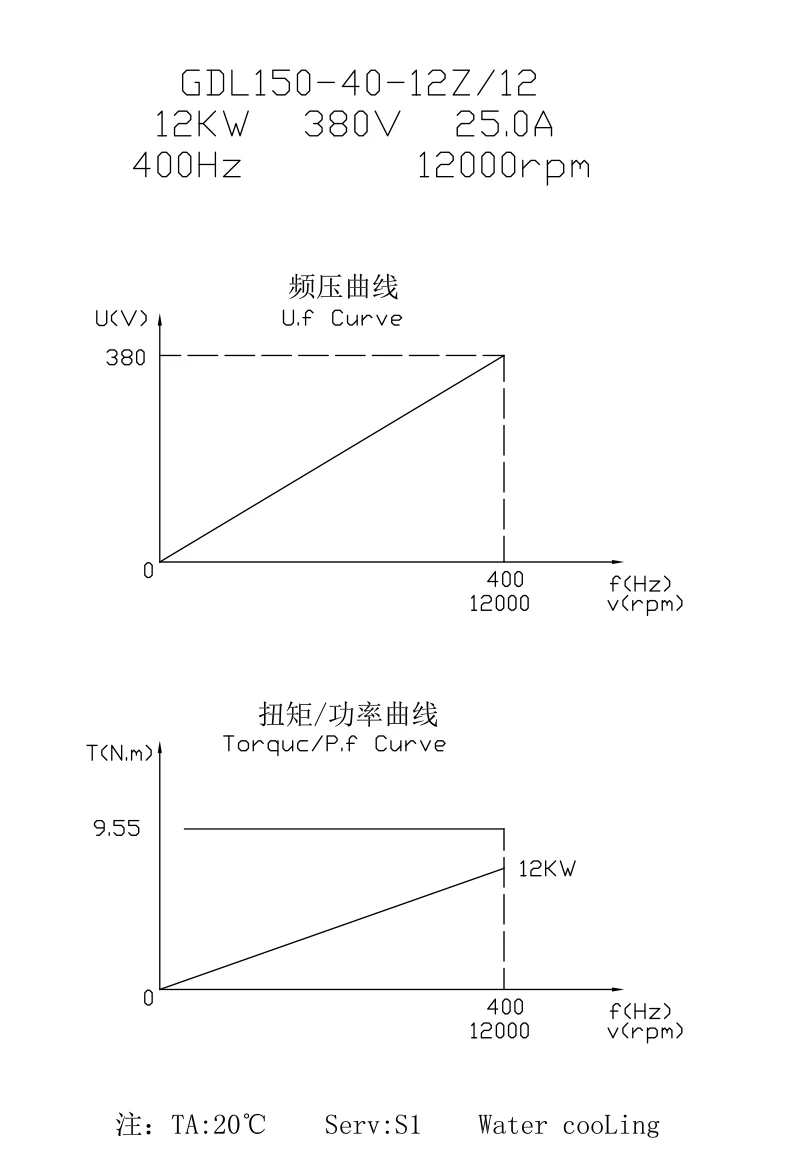

- Speed regulation mode: The three-phase output inverter can change the spindle speed by changing the frequency of the inverter.

- Cooling method: water cooling

- Power: 12kw

- Voltage: 380V

- Current: 25A

- Torque: 9.55Nm

- Frequency:400HZ

- Speed: 12000RPM

- Number of poles: 4P

- Phase: 3 phase asynchronous driver

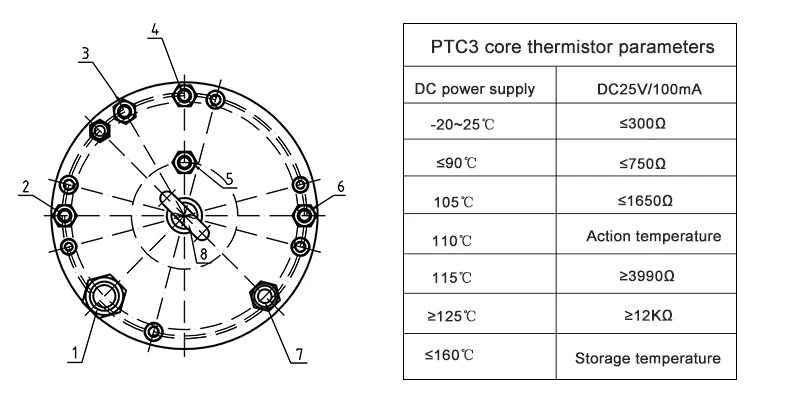

- Bearing: 2*SM6011C/P4,2*7008C/P4

- Rotation: Seen from the shaft end, it rotates counterclockwise

- Tool handle: BT40

- Pull stud: BT40-45°

- Grease lubrication

- Main use: Carving wood, bamboo, ordinary PCB, PVC, PMMA, plastic, two-color board (ABS) and other non-metals.

Key Features of the ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer

High-Power 12kw Motor

The 12kw CNC spindle motor delivers significant power, making it suitable for a broad range of machining tasks. Its robust power output ensures efficient cutting, milling, and drilling of diverse materials, including metals, plastics, and composites. This high power capacity allows for seamless performance even during demanding operations.

Advanced Water Cooling System

The spindle is equipped with an advanced water cooling system that maintains optimal operating temperatures during prolonged use. The water cooling mechanism prevents overheating, ensuring consistent performance and extending the spindle’s lifespan. This feature is particularly beneficial for high-speed and continuous machining processes.

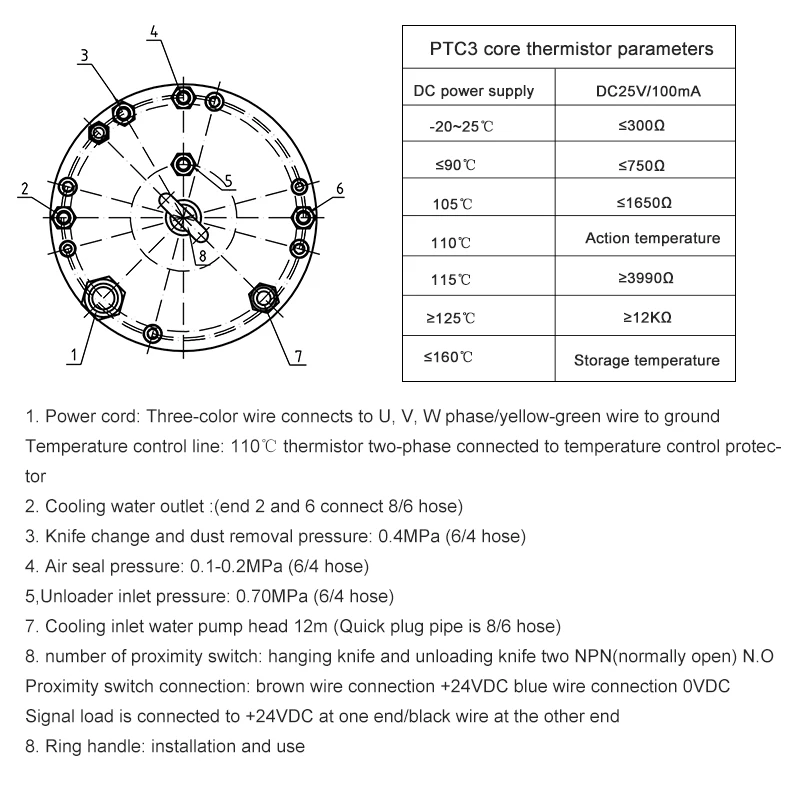

Automatic Tool Changer (ATC)

The integrated automatic tool changer (ATC) is a significant advantage, enabling rapid and seamless tool changes. This automation minimizes manual intervention, boosting productivity and allowing for complex machining tasks to be completed more efficiently. The ATC feature is essential for operations that require multiple tools in quick succession.

Benefits of Using the ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer

Superior Precision and Accuracy

The ATC Spindle 12kw Water Cooled Spindle excels in delivering superior precision and accuracy. Its design ensures minimal runout and vibration, resulting in highly accurate machining outcomes. This precision is critical for industries such as aerospace, automotive, and mold making, where exact tolerances are required.

Enhanced Productivity

With its powerful motor, efficient cooling, and automatic tool changing capability, this spindle significantly enhances productivity. Machinists can perform complex operations faster and with greater reliability, meeting tight production deadlines and improving overall throughput. The ability to handle demanding tasks effortlessly makes this spindle a valuable asset.

Long-Lasting Durability

Investing in the ATC Spindle 12kw Water Cooled Spindle means investing in a durable and reliable piece of equipment. The advanced water cooling system not only enhances performance but also contributes to the spindle’s longevity by preventing overheating and reducing wear and tear. This durability ensures a high return on investment, as the spindle can withstand the demands of daily use in challenging environments.

Applications of the ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer

CNC Milling and Drilling

The ATC Spindle 12kw Water Cooled Spindle is ideal for CNC milling and drilling operations. Its high power and precision make it suitable for creating intricate components and parts with high dimensional accuracy. Whether it’s milling metal parts or drilling precise holes, this spindle delivers exceptional performance.

Woodworking and Cabinetry

In the woodworking industry, precision and speed are crucial. The water-cooled spindle ensures that intricate designs and cuts can be made efficiently without compromising on quality. This makes it perfect for furniture making, cabinetry, and other woodworking applications.

Machining Composite Materials

Machining composite materials requires a spindle that can handle varying densities and toughness. The 12kw ATC Spindle excels in this area, providing the necessary power and stability to machine composites accurately, making it an excellent choice for the aerospace and automotive industries.

Conclusion of ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer

The ATC Spindle 12kw Water Cooled Spindle Automatic Tool Changer is a remarkable addition to any CNC machining setup. Its combination of high power, advanced water cooling, and automatic tool changing capability ensures superior precision, enhanced productivity, and exceptional durability. Whether you’re involved in metalworking, woodworking, or composite machining, this spindle offers the performance and reliability needed to elevate your operations.