ATC Spindle 12KW Automatic Tool Change Air cooled Spindle

Description

ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle

The ATC Spindle 12KW Automatic Tool Change Air Cooled Spindleis a top-tier solution in CNC machining, offering unparalleled power, efficiency, and precision. This advanced spindle motor, equipped with an automatic tool changer (ATC) and an efficient air-cooled system, is designed to meet the rigorous demands of modern industrial applications. This article explores its features, applications, benefits, and technical specifications, optimizing for SEO with related keywords to provide a comprehensive overview for potential users and buyers.

Features of ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle

- High Power Output:

- The 12KW CNC ATC Spindle Motor delivers exceptional power, making it ideal for heavy-duty machining tasks. Its robust performance ensures rapid material removal and precise machining, essential for complex and demanding projects.

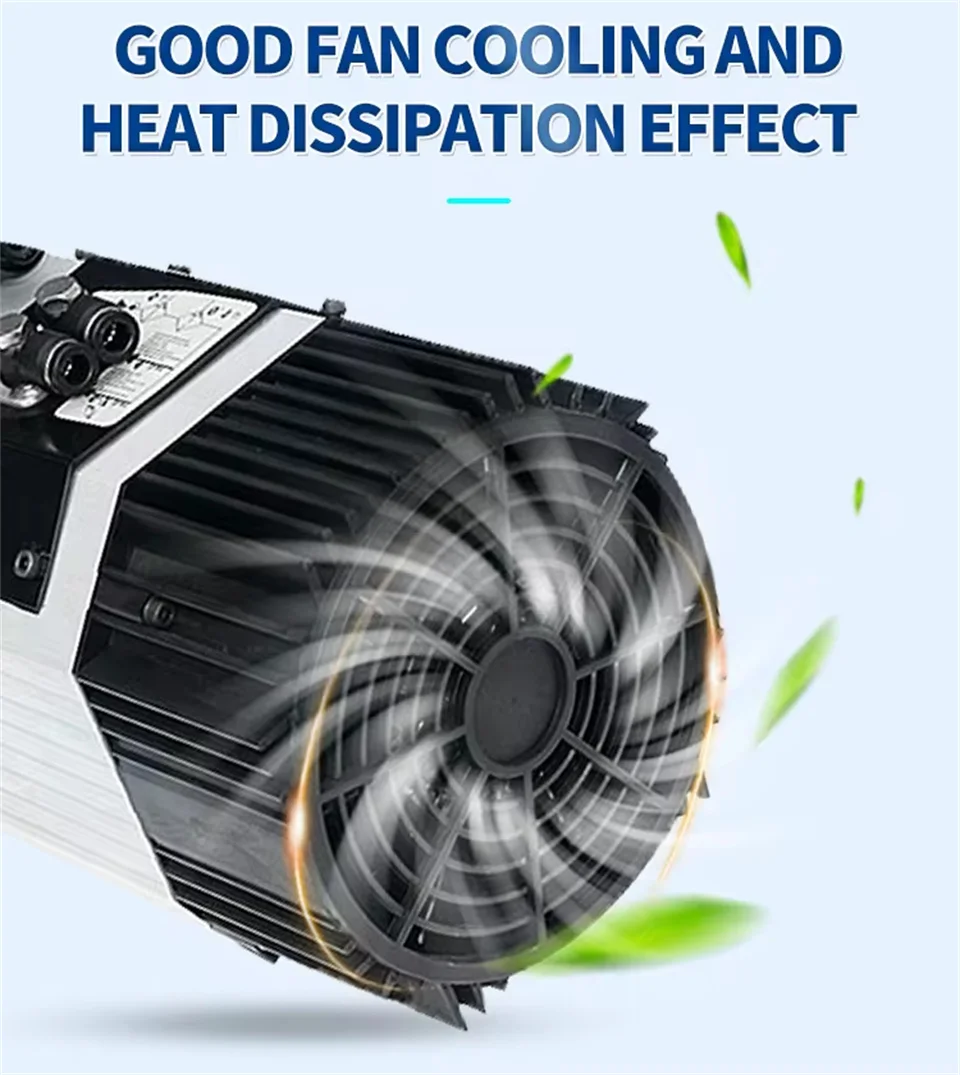

- Air-Cooled System:

The advanced air-cooled cooling system efficiently manages heat dissipation, preventing overheating and ensuring consistent performance. This feature simplifies maintenance and reduces the need for external cooling setups. - Automatic Tool Changer (ATC):

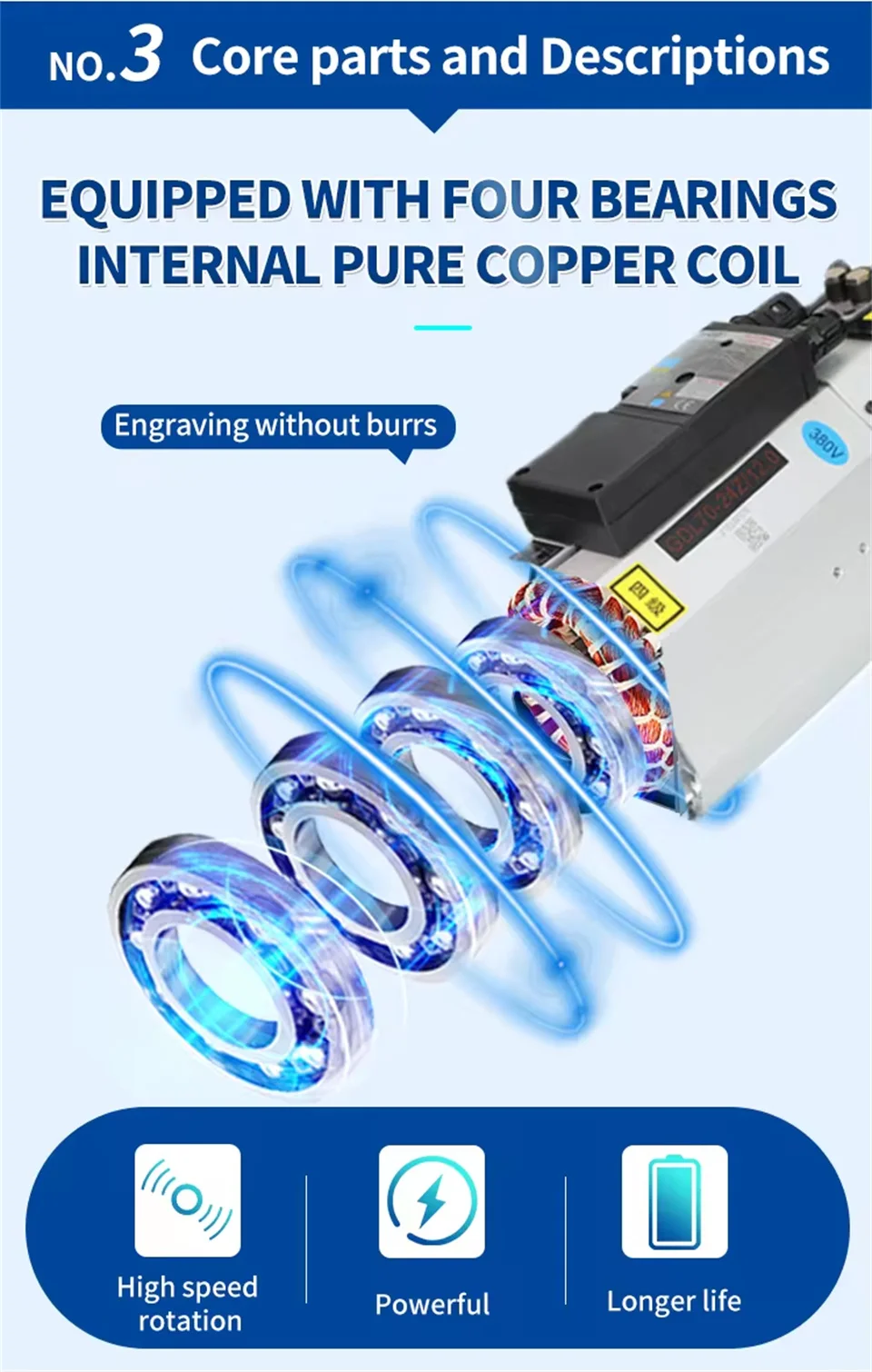

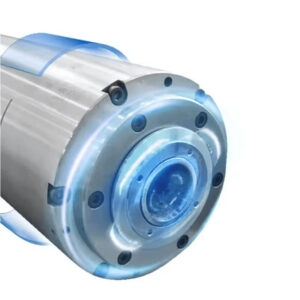

The integrated ATC enhances productivity by allowing quick and seamless tool changes. This reduces manual intervention, minimizes downtime, and boosts overall machining efficiency. - Precision Bearings:

Equipped with high-precision ceramic bearings, the spindle motor minimizes friction and vibration. This configuration ensures smooth operation, high accuracy, and superior surface finishes. - Versatile Compatibility:

This spindle motor is compatible with various materials, including wood, metals, plastics, and composites. Its versatility makes it suitable for a wide range of applications, from milling and drilling to engraving and cutting.Applications of ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle

The ATC Spindle 12KW Automatic Tool Change Air Cooled Spindleis widely used across multiple industries:

– Woodworking:Ideal for precision carving, shaping, and cutting wood, enhancing the production of furniture, cabinetry, and artistic creations.

– Metalworking:Efficient in machining metals such as aluminum, brass, and stainless steel, crucial for automotive, aerospace, and industrial components.

– Plastic and Composite Machining:Ensures accurate processing of plastics and composite materials, commonly used in electronics, consumer goods, and prototyping applications.

– Engraving and Prototyping:Facilitates detailed engraving and rapid prototyping, delivering intricate designs and high-quality finishes.

Benefits of Using ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle

-Enhanced Productivity: The automatic tool changer significantly reduces manual tool changes, decreasing downtime and increasing machining efficiency.

-Superior Performance: The 12KW power output and precision engineering provide high torque and speed capabilities, essential for complex machining operations.

-Reliability: Built with durable materials and advanced ceramic bearings, the spindle motor ensures reliable performance, minimal maintenance, and extended operational lifespan.

-Precision: Maintains tight tolerances and minimal runout, enabling precise machining and consistent production of high-quality components.

-Cost Efficiency: The efficient air-cooling system reduces maintenance needs and operational costs, optimizing overall productivity.

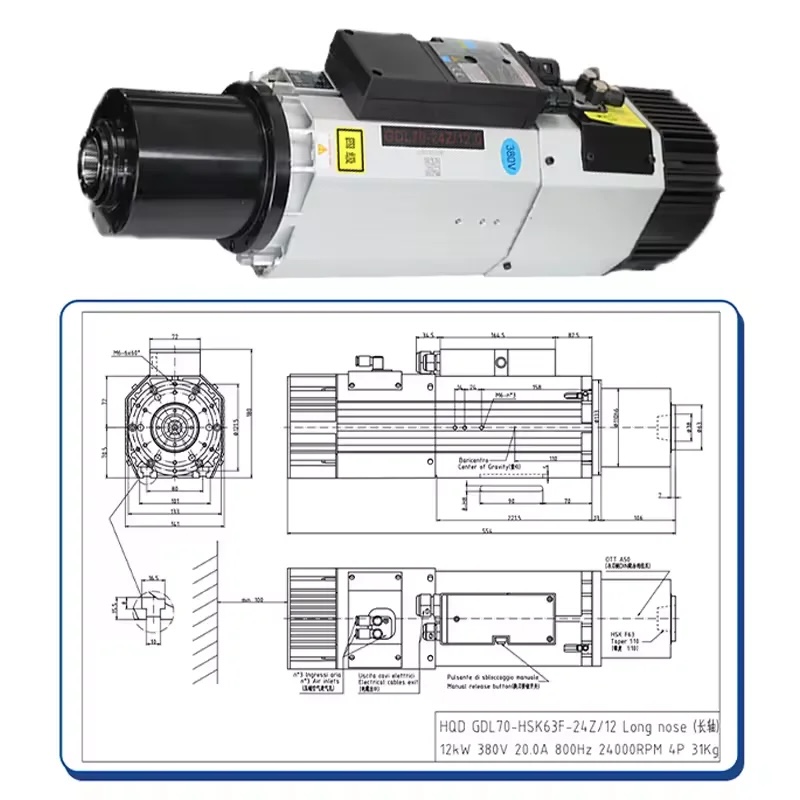

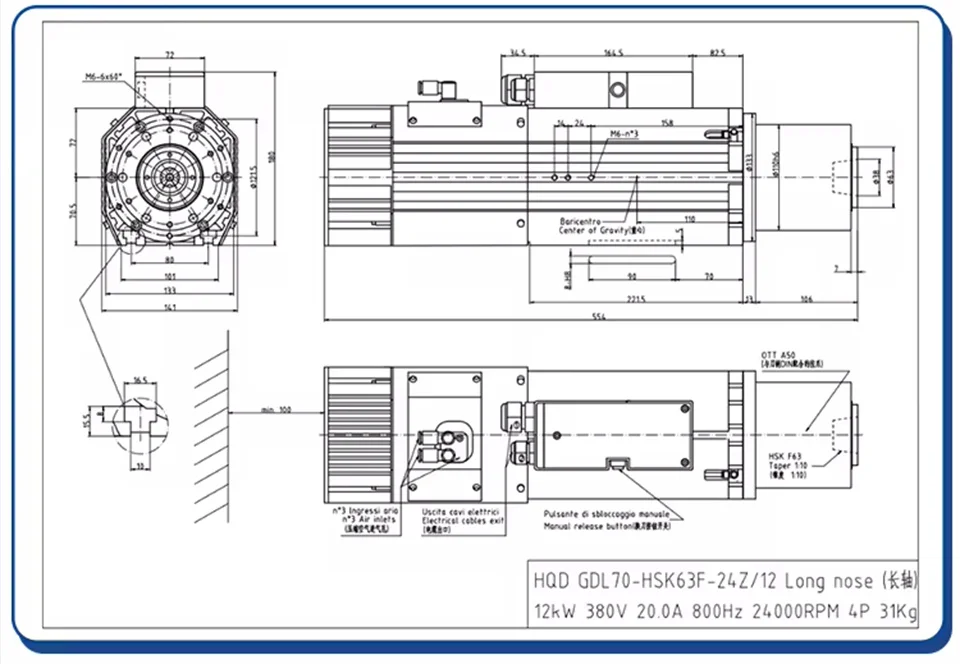

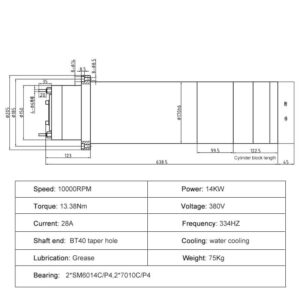

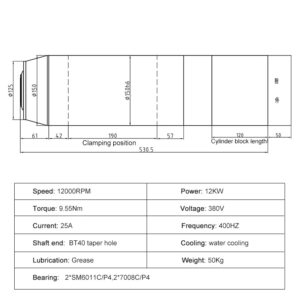

Technical Specifications

– Power Output: 12KW

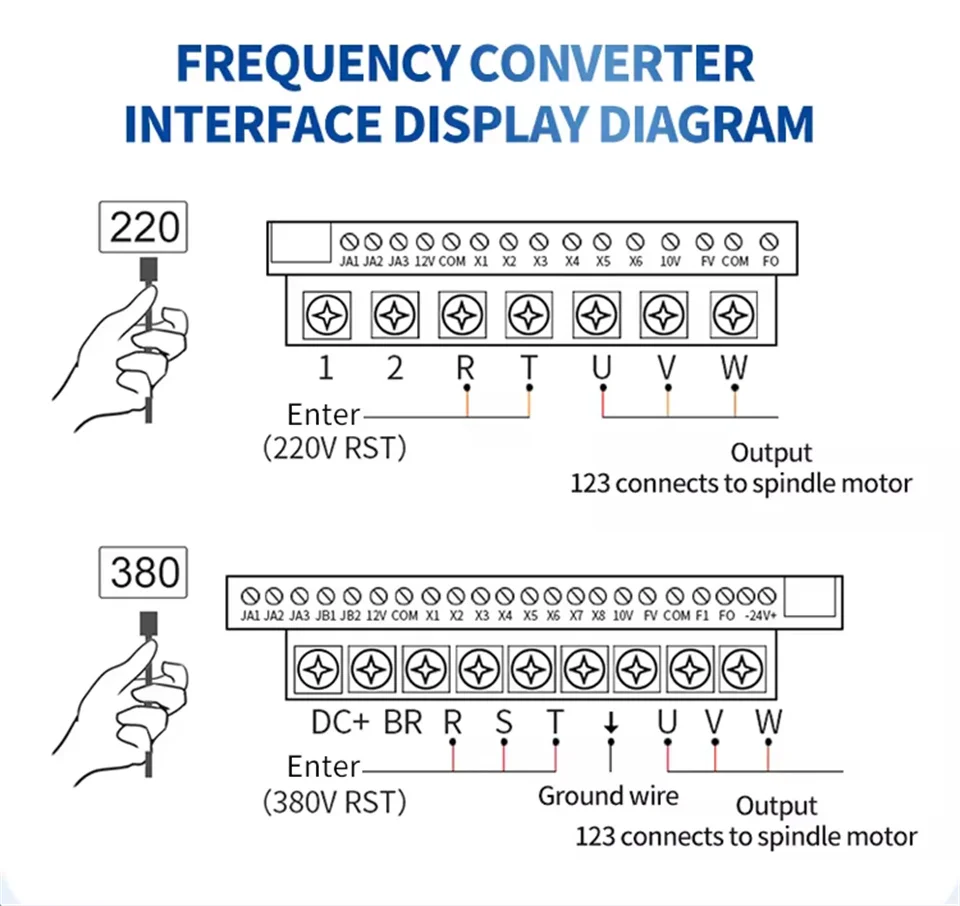

– Cooling System: Air-cooled

– Bearings: High-precision ceramic bearings

– Tool Changer: Automatic Tool Changer (ATC)

– Material Compatibility: Wood, metals, plastics, and composites

– Applications: Milling, drilling, engraving, and cutting

Why Choose the ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle?

Choosing the ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle offers several advantages:

– Efficiency: Enhanced cooling system and ATC reduce operational downtime and improve machining throughput.

– Versatility: Capable of handling a diverse range of materials and applications, making it a flexible solution for various industries.

– Durability: High-quality construction and precision bearings ensure long-lasting performance and reliability.

– Cost-Effective: Reduces the need for frequent maintenance and minimizes operational costs, offering a high return on investment.

Conclusion

The ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle is a powerful and efficient solution for modern CNC machining. Its high power output, efficient air-cooled system, and automatic tool changer make it a valuable asset for various industrial applications. Whether you are involved in woodworking, metalworking, plastic machining, or prototyping, this spindle motor ensures superior performance, reliability, and precision.

Investing in the ATC Spindle 12KW Automatic Tool Change Air Cooled Spindle not only enhances your machining capabilities but also provides a competitive edge in the fast-paced manufacturing landscape. Embrace this advanced technology to achieve optimal machining results and drive your production efficiency to new heights.