7.5KW Spindle Motor Air Cooled 4 Bearings CNC Square Spindle

Description

7.5KW Spindle Motor Air Cooled 4 Bearings CNC Square Spindle

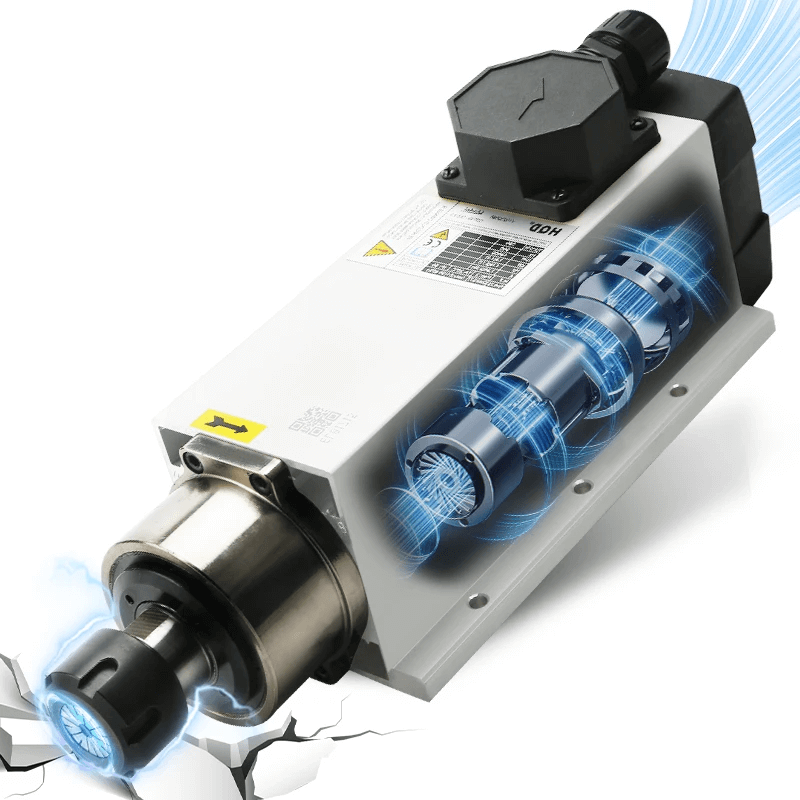

The 7.5KW spindle motor is a high-performance component designed for CNC machining, renowned for its air-cooled system and robust construction featuring 4 bearings. This article explores the capabilities, applications, and benefits of the 7.5KW air-cooled CNC spindles.

7.5KW Spindle Motor Air Cooled 4 Bearings CNC Square Spindle

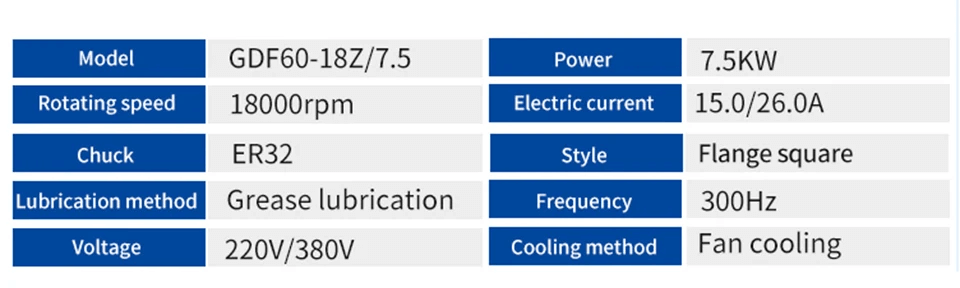

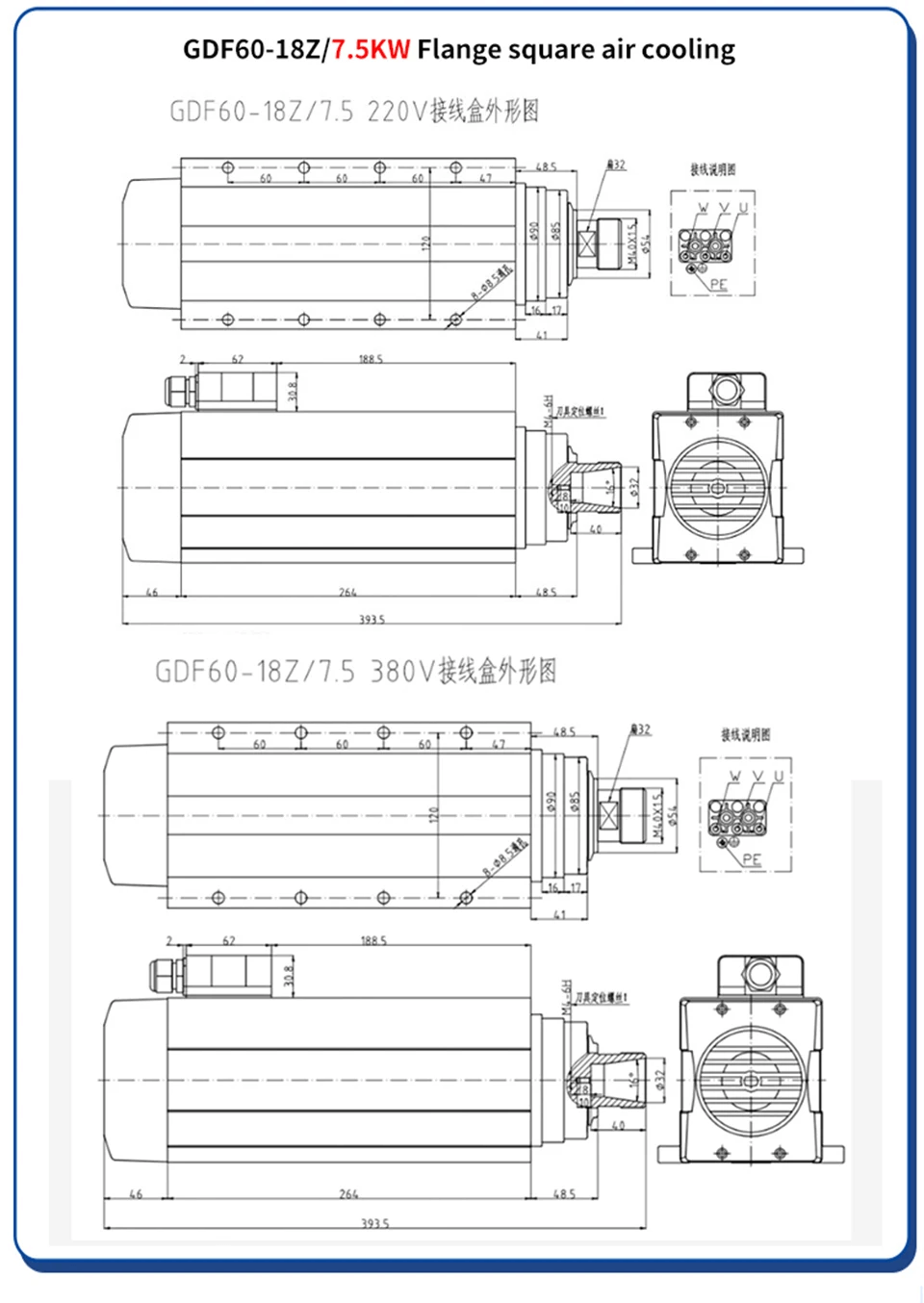

- Model: GDF46-18Z/7.5

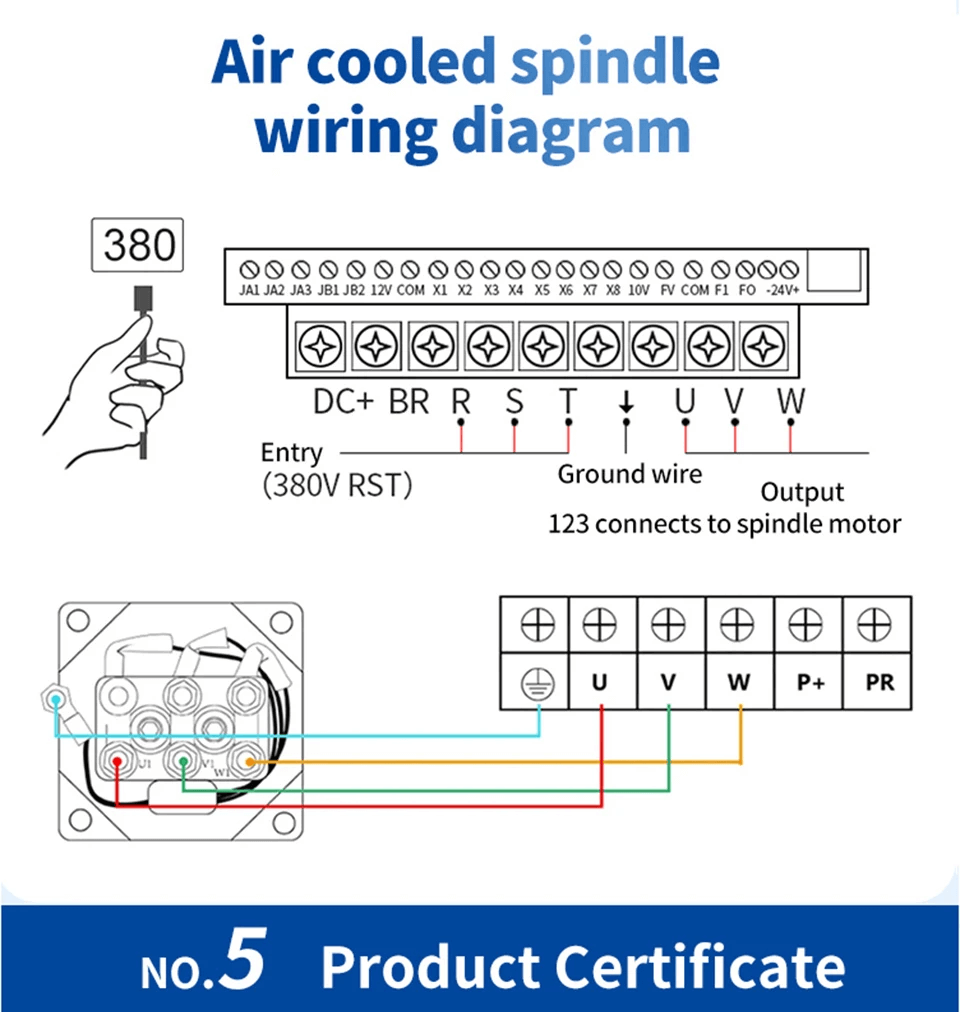

- Speed Regulation Mode: The spindle speed is adjusted using a three-phase output inverter, controlling frequency.

- Cooling Method: Air-cooled.

- Power Interface: Optional 5-pin waterproof air connector. Connections are labeled “1”, “2”, “3”, “4”, “5”, and “GND”. “1”, “2”, and “3” connect to the inverter (U, V, W), and “GND” connects to the inverter ground.

- (Attention! Connect spindle “4” to GND for personal safety!)

- Power: 7.5 kW (1 HP = 0.735 kW).

- Voltage: 380V.

- Current: 15A/26A

- Frequency: 0-300Hz.

- Speed: 0-18,000 RPM.

- Runout: Less than 0.01mm.

- Bearing Type: 2 × 7008C P4, 2 × 7002C P4 (4 ball bearings).

- Chuck: ER32.

- Clamping Tool Diameter: 1mm, 2mm, 3mm, 3.175mm (1/8″), 4mm, 5mm, 6mm, 6.35mm (1/4″), 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, 12.7mm (1/2″), 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm, 20mm.

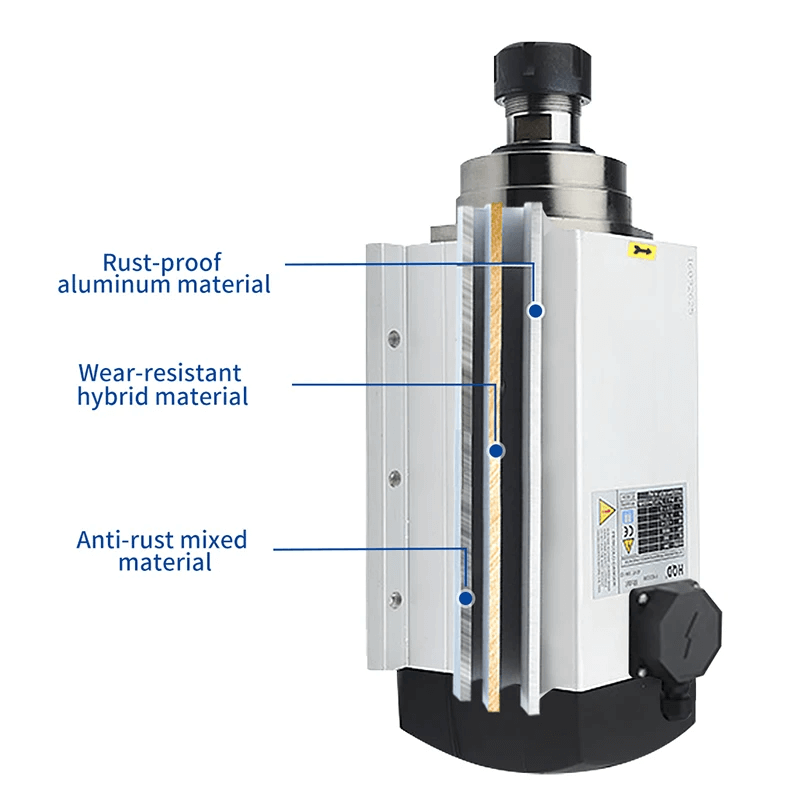

- Lubrication: Grease lubrication.

- Main Use: Specifically designed for carving non-metal materials such as wood, bamboo, PVC, PMMA, and two-color boards (ABS). It can also engrave soft metal surfaces like gold, silver, copper, aluminum, and lead.

- (Note: This spindle is suitable for woodworking and aluminum products, not steel. For steel applications, please consider a metal-specific spindle. Thank you!)

- Power and Efficiency:

The 7.5KW spindle motor delivers substantial power, making it suitable for heavy-duty machining operations. Its efficiency ensures rapid material removal and precise machining, enhancing productivity. - Cooling System:

Equipped with an air-cooled mechanism, this spindle motor efficiently dissipates heat during operation. This cooling method reduces maintenance requirements and ensures consistent performance over extended periods. - Bearing Configuration:

Featuring 4 bearings, including high-precision ceramic bearings, the spindle motor maintains stability and minimizes vibration, crucial for achieving smooth finishes and accurate cuts. - Versatility in Applications:

The spindle motor is versatile, capable of machining a wide range of materials including wood, plastics, composites, and non-ferrous metals. It is ideal for tasks such as milling, drilling, engraving, and cutting, catering to diverse industrial needs. - Compatibility and Integration:

Designed for seamless integration into CNC machines, the spindle motor supports various collet sizes and interfaces with standard CNC controllers. Its robust design ensures reliability in demanding manufacturing environments.

Applications of 7.5KW Spindle Motor Air Cooled 4 Bearings CNC Square Spindle

The 7.5KW spindle motor finds application across multiple industries:

– Woodworking: Carving, cutting, and shaping wood for furniture, cabinetry, and artistic creations.

– Metalworking: Precision milling, drilling, and engraving of metals like aluminum, brass, and copper for automotive and aerospace components.

– Plastic and Composite Machining: Accurate machining of plastics and composite materials used in electronics, consumer goods, and industrial applications.

– Engraving and Prototyping: Detailed engraving and rapid prototyping in various materials, ensuring intricate designs and high-quality finishes.

Benefits of Using7.5KW Spindle Motor Air Cooled 4 Bearings CNC Square Spindle

– High Performance: Provides high torque and speed capabilities, essential for achieving complex machining tasks efficiently.

– Reliability: Built with durable materials and advanced cooling technology, ensuring consistent performance and extended operational life.

– Precision: Maintains tight tolerances and minimal runout, enabling precise machining and superior surface finishes.

– Cost Efficiency: Enhances productivity and reduces downtime with its efficient cooling system and low maintenance requirements.

Conclusion

The 7.5KW spindle motor with air-cooled technology and 4 bearings is an indispensable tool for modern CNC machining operations. Its power, reliability, and versatility make it suitable for a wide range of applications across woodworking, metalworking, plastics machining, and beyond. Whether for small-scale production or large-scale manufacturing, this spindle motor ensures optimal performance and exceptional results.