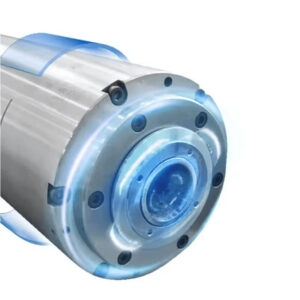

5.5KW BT30 ATC Water Cooled Spindle Motor Auto Tool Changer

Description

5.5KW BT30 ATC Water Cooled Spindle Motor Auto Tool Changer

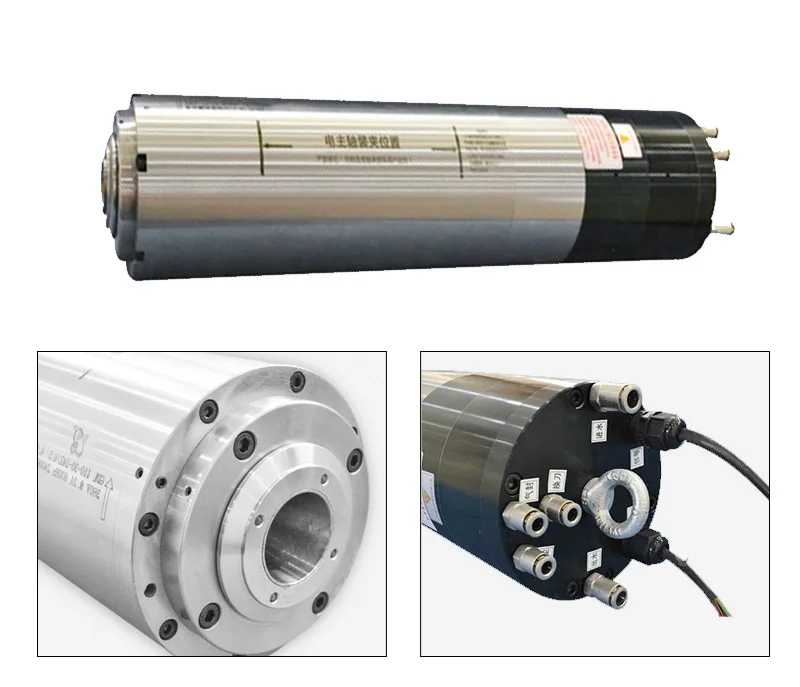

In the world of CNC (Computer Numerical Control) machining, the spindle motor is the heart of the machine, providing the power and precision needed for high-quality production. One of the standout products in this domain is the 5.5KW BT30 ATC Water Cooled Spindle Motor Auto Tool Changer. This spindle motor is a game-changer for industries requiring precision, speed, and efficiency.

The specification of 5.5KW BT30 ATC Water Cooled Spindle Motor Auto Tool Changer

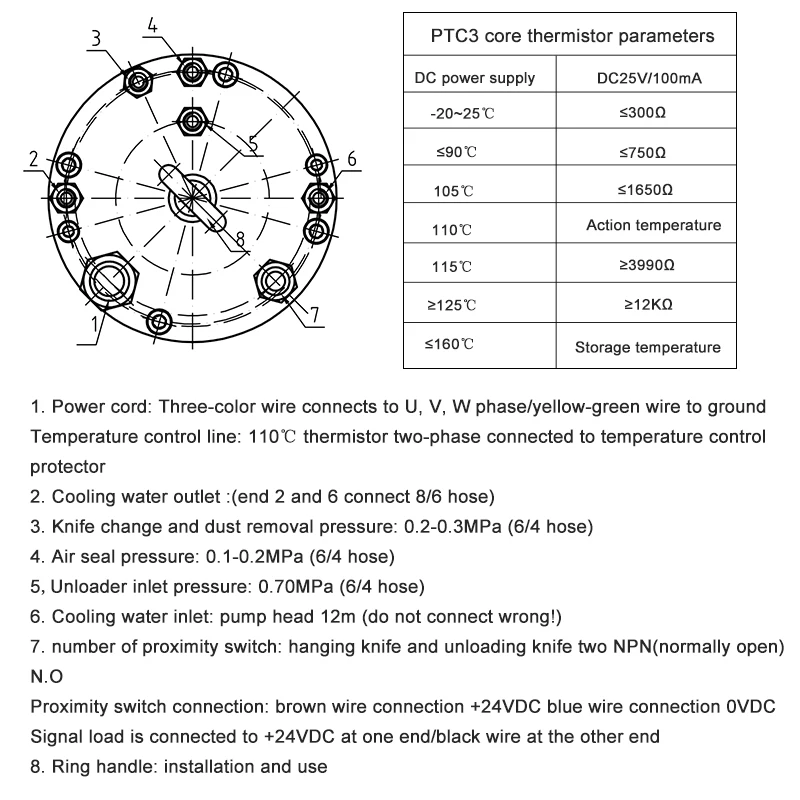

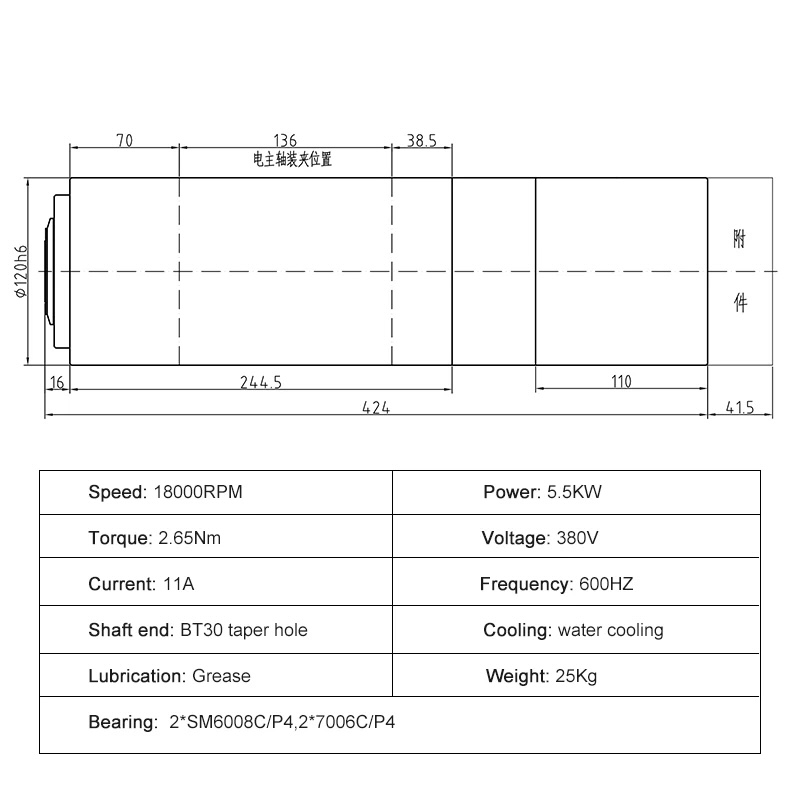

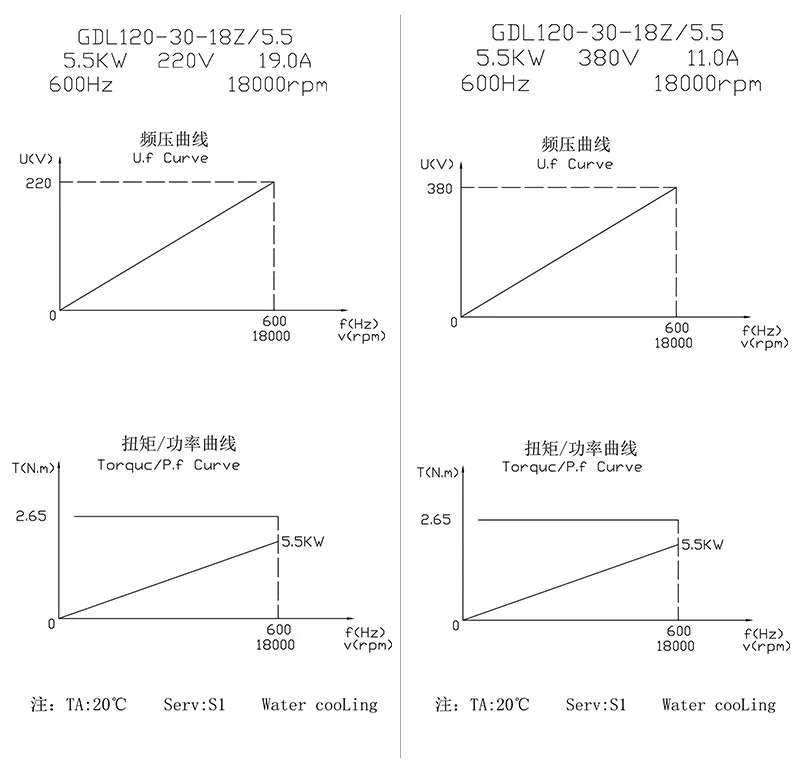

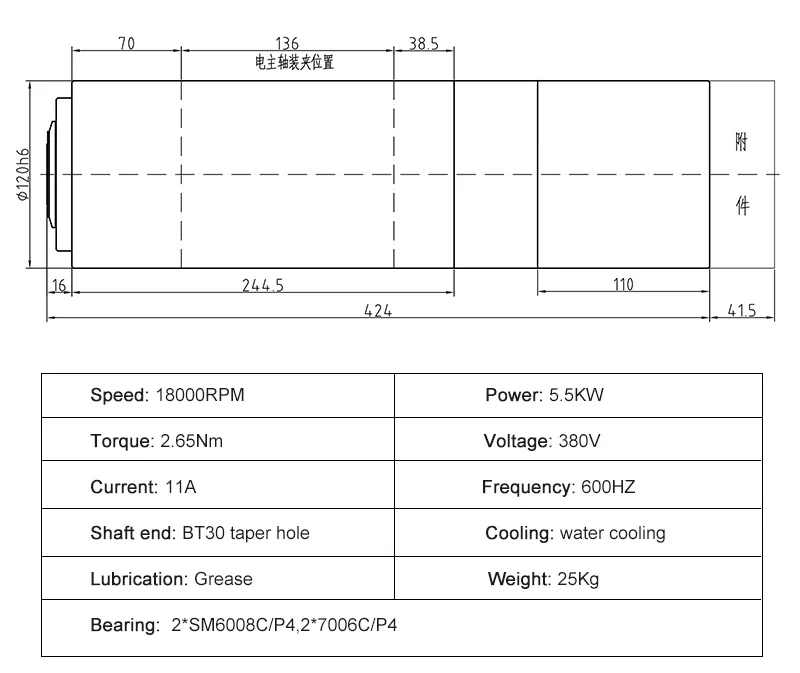

- Model: GDL120-30-18Z/5.5

- Diameter (mm): 120

- Speed regulation mode: The three-phase output inverter can change the spindle speed by changing the frequency of the inverter.

- Cooling method: water cooling

- Power: 5.5 kw

Voltage: 380 V - Current: 11 A

- Torque: 2.65 NM

- Frequency:600 HZ

- Speed: 18000 RPM

- Number of poles: 4 P

- Phase: 3 phase asynchronous driver

- Rotation: Seen from the shaft end, it rotates counterclockwise

- Tool handle: BT30 ER32

- Pull stud: BT30-45°

- Grease lubrication

Main use: Carving wood, bamboo, ordinary PCB, PVC, PMMA, plastic, two-color board (ABS) and other non-metals.

Key Features of the 5.5KW BT30 ATC Water Cooled Spindle Motor

When choosing a spindle motor, understanding its features is crucial. The 5.5KW BT30 ATC Water Cooled Spindle Motor Auto Tool Changer boasts a plethora of advanced features:

- Powerful 5.5KW Motor: The 5.5KW motor provides ample power for a wide range of machining tasks, from heavy-duty cutting to fine detailing.

- BT30 Tool Holder: The BT30 tool holder is renowned for its reliability and ease of use, ensuring quick tool changes and minimal downtime.

- Auto Tool Changer (ATC): The ATC feature automates the tool changing process, significantly improving workflow efficiency and reducing manual intervention.

- Water Cooling System: The water cooling system helps maintain optimal operating temperatures, ensuring the motor runs smoothly and prolonging its lifespan.

Advantages of Using a 5.5KW BT30 ATC Water Cooled Spindle Motor

The benefits of integrating the 5.5KW BT30 ATC Water Cooled Spindle Motor into your CNC machine are manifold:

- Enhanced Precision: The stability provided by the water cooling system, combined with the precision of the BT30 tool holder, results in highly accurate machining.

- Increased Productivity: The ATC feature minimizes the time spent on manual tool changes, allowing for continuous operation and higher productivity.

- Durability and Longevity: Efficient cooling and robust construction mean that this spindle motor is built to last, offering long-term reliability and performance.

Applications of the 5.5KW BT30 ATC Water Cooled Spindle Motor

This spindle motor is versatile and can be used across various industries:

- Aerospace: Ideal for machining aerospace components that require high precision and quality.

- Automotive: Suitable for manufacturing automotive parts, ensuring consistency and durability.

- Woodworking: Perfect for detailed woodworking tasks, from cabinetry to intricate designs.

- Metalworking: Capable of handling both heavy-duty cutting and fine metalwork.

Installation and Maintenance Tips

Proper installation and maintenance are key to getting the most out of your 5.5KW BT30 ATC Water Cooled Spindle Motor:

- Installation: Ensure that the spindle motor is correctly aligned and securely mounted. Follow the manufacturer’s guidelines for electrical connections and cooling system setup.

- Regular Maintenance: Regularly check the cooling system for leaks and ensure that the water is clean. Lubricate moving parts as recommended and inspect the motor for any signs of wear or damage.

Conclusion of 5.5KW BT30 ATC Water Cooled Spindle Motor Auto Tool Changer

The 5.5KW BT30 ATC Water Cooled Spindle Motor Auto Tool Changer is a powerful, efficient, and versatile component for any CNC machine. Its advanced features and robust design make it an excellent choice for industries requiring high precision and reliability. By integrating this spindle motor into your machining setup, you can enhance productivity, ensure quality, and achieve superior results.