4.5kw Water Cooled Spindle Motor chuck ER20 Machine Spindle

Description

4.5KW Water Cooled Spindle Motor Chuck ER20 Machine Spindle

Introduction

The 4.5KW Water Cooled Spindle Motor chuck ER20 Machine Spindle is a powerhouse in the world of CNC machining. Designed for high-performance and precision, this spindle motor is ideal for various demanding applications. This article explores the features, parameters, applications, suitable materials, and industry areas for this advanced spindle motor, providing a comprehensive guide for professionals and enthusiasts.

Features of the 4.5KW Water Cooled Spindle Motor Chuck ER20 Machine Spindle

High Power Output

With a robust 4.5KW power output, this spindle motor delivers exceptional performance for heavy-duty machining tasks. It provides the necessary torque and speed for efficient and precise material removal, making it suitable for a wide range of applications.

Efficient Water Cooling System

The integrated water cooling system ensures that the spindle operates at optimal temperatures, preventing overheating during extended use. This not only enhances performance but also prolongs the lifespan of the spindle motor, ensuring reliable and continuous operation.

Precision and Stability

The spindle motor features high-precision bearings and an ER20 chuck, offering superior stability and accuracy. This ensures smooth and precise cuts, which is crucial for detailed machining and engraving projects.

Low Noise Operation

Compared to air-cooled alternatives, this water-cooled spindle operates at significantly lower noise levels. This feature is particularly beneficial for environments where noise reduction is important, creating a more comfortable working space.

Durability and Reliability

Constructed from high-quality materials, the 4.5KW Water Cooled Spindle Motor chuck ER20 Machine Spindle is built to withstand continuous use in demanding conditions. Its robust design reduces the need for frequent maintenance and ensures long-term reliability.

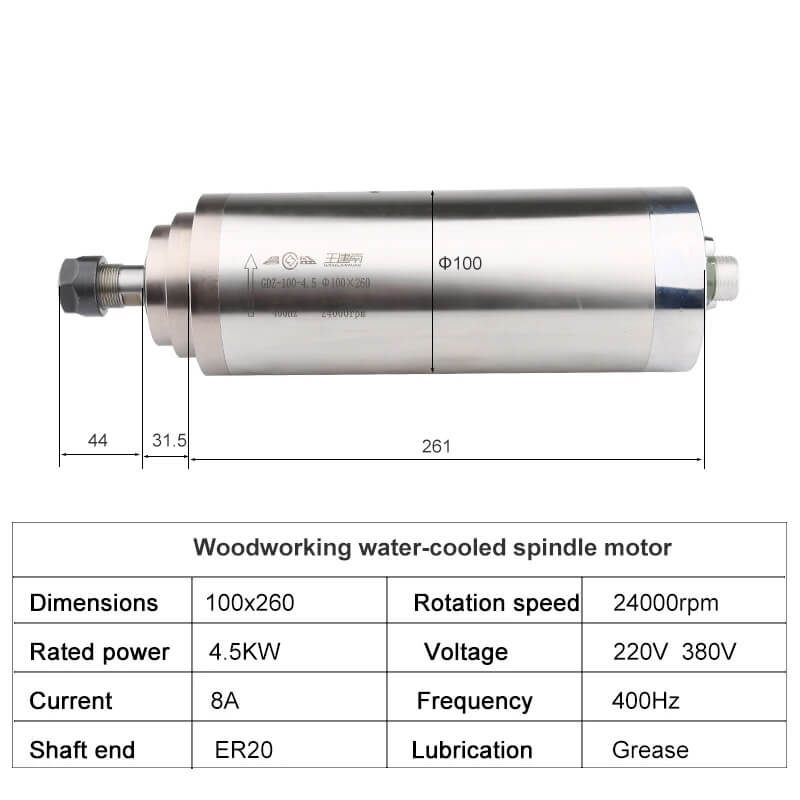

Key Parameters

- iddle body diameter: Φ100*260mm

- Speed regulation mode: change the spindle speed through the three-phase output inverter and adjusting the frequency of the inverter.

- Cooling method: water cooling

- Power interface: optional YH20-4 pin waterproof aviation plug. Aviation plugs marked “1”, “2”, “3”, “4”, “1”, “2”, “3” are connected to the inverter (U, V, W), and 4 are connected to the inverter Ground the equipment.

- Power: 4.5kw

- Voltage: 220v 380V

- Current: 8A

- Frequency: 400Hz

- Speed: 24000rpm

- Runout: less than 0.01mm

- Number of phases: 3

- Chuck: ER20

- Grease lubrication

- Main purpose: used for wood, bamboo, ordinary PCB, PVC, PMMA, plastic, bamboo, two-color board (ABS) and other non-metallic carving

Applications of the 4.5KW Water Cooled Spindle Motor Chuck ER20 Machine Spindle

Wood Engraving

This spindle motor is perfect for wood engraving applications. It excels in tasks such as cutting, carving, and detailed engraving, ensuring high precision and efficiency in every operation.

CNC Machining

Beyond wood engraving, this spindle motor is suitable for various CNC machining applications, including milling and drilling. Its high power and precision capabilities make it a versatile tool in the CNC machining arsenal.

Sign Making

In the sign-making industry, precision and detail are paramount. This spindle motor provides the necessary performance to create intricate and professional signs from various materials.

Prototyping and Custom Fabrication

For prototyping and custom fabrication, this spindle motor offers the flexibility and accuracy needed to create prototypes and custom parts with ease. Its reliable performance ensures high-quality results in every project.

Suitable Materials for the 4.5KW Water Cooled Spindle Motor Chuck ER20 Machine Spindle

- Wood: Softwood, hardwood, plywood, MDF

- Metals: Light metals such as aluminum

- Plastics: Acrylic, PVC, ABS, polycarbonate

- Composites: Carbon fiber, fiberglass, laminates

Industry Areas Benefiting from the 4.5KW Water Cooled Spindle Motor Chuck ER20 Machine Spindle

Furniture Manufacturing

In the furniture manufacturing industry, precision and quality are essential. This spindle motor ensures accurate and detailed cuts, making it ideal for creating high-quality furniture pieces.

Sign Making

Sign making requires precise cutting and engraving capabilities. This spindle motor provides the necessary power and stability to create professional signs from various materials.

Woodworking Shops

Woodworking shops benefit greatly from the versatility and precision of this spindle motor. It can handle a variety of tasks, from intricate engravings to heavy-duty cutting and carving.

DIY Enthusiasts and Hobbyists

DIY enthusiasts and hobbyists can also benefit from this spindle motor. Its user-friendly design and high performance make it suitable for a wide range of DIY projects, from crafting to home improvement.

Focus FAQ for 4.5KW Water Cooled Spindle Motor Chuck ER20 Machine Spindle

What is a CNC spindle motor?

A CNC spindle motor is a crucial component of CNC machines, providing the rotational force needed for cutting, carving, and engraving materials with high precision and efficiency.

What are the benefits of a water cooled spindle motor?

Water cooled spindle motors offer efficient heat dissipation, reduced noise levels, and prolonged operational life compared to air-cooled counterparts. They are ideal for continuous and heavy-duty machining tasks.

How do I maintain a water cooled spindle motor?

Regularly inspect and clean the cooling system to prevent clogs, check for wear and tear on moving parts, and ensure proper lubrication as per the manufacturer’s guidelines. Proper maintenance ensures optimal performance and longevity.

Can this spindle motor be used for metalworking?

Yes, this spindle motor can handle light metalworking tasks, such as machining aluminum. However, it is primarily designed for wood and plastic materials.

What factors should I consider when choosing a CNC spindle motor?

Consider the power output, cooling method, speed range, chuck size, compatibility with your CNC machine, and the specific requirements of your application. Consulting with the manufacturer or a professional can help you make an informed decision.

Conclusion

The 4.5KW Water Cooled Spindle Motor chuck ER20 Machine Spindle is a powerful and versatile tool designed to meet the demands of high-precision and heavy-duty machining tasks. Its efficient cooling system, precision bearings, and robust construction make it an invaluable asset in various industries. By understanding its features, parameters, applications, and suitable materials, you can maximize its potential and achieve exceptional results in your projects.