4.5KW ATC Water Cooled Spindle Motor Automatic Tool Changer

Description

The 4.5KW ATC Water Cooled Spindle Motor Automatic Tool Changer represents a significant advancement in CNC (Computer Numerical Control) technology, offering enhanced performance, reliability, and efficiency. This innovative spindle motor is designed for various industrial applications, providing a robust solution for tasks that demand precision and high-speed operations. In this article, we will explore the key features, benefits, and applications of this state-of-the-art spindle motor, along with related keywords to optimize understanding and searchability.

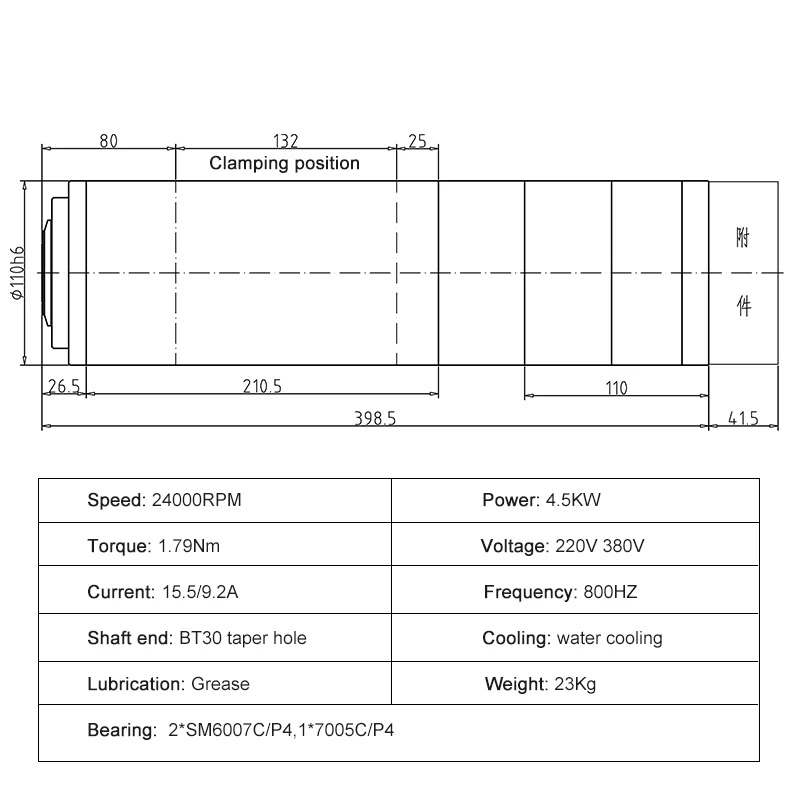

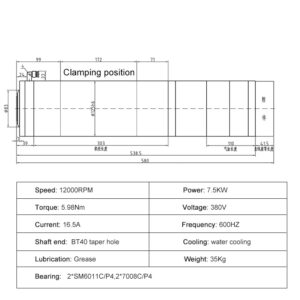

The specifcaition of 4.5KW ATC Water Cooled Spindle Motor Automatic Tool Changer

- Model: GDL110-30-24Z/4.5

- Diameter (mm):110

- Speed regulation mode:The three-phase output inverter can change the spindle speed by changing the frequency of the inverter.

- Cooling method: water cooling

- Power:4.5kw

- Voltage:220V 380V

- Current:15.5/9.2A

- Torque:1.79Nm

- Frequency:800Hz

- Speed:24000RPM

- Number of poles:4 P

- Phase:3 phase asynchronous driver

- Rotation:Seen from the shaft end, it rotates counterclockwise

- Tool handle:BT30 ER32

- Pull stud:BT30-45°

- Grease lubrication

- Main use:Carving wood, bamboo, ordinary PCB, PVC, PMMA, plastic, two-color board (ABS) and other non-metals.

Key Features of the 4.5KW ATC Water Cooled Spindle Motor Automatic Tool Changer

The 4.5KW ATC Water Cooled Spindle Motor is packed with features that make it an essential component for modern CNC machines. Below are some of the standout attributes:

High Power and Efficiency

With a power rating of 4.5KW, this CNC spindle motor delivers impressive torque and speed, enabling efficient cutting, milling, and drilling operations. The high power ensures that the motor can handle a wide range of materials, from metals to plastics, with ease.

Advanced Cooling System

The water-cooled spindle system ensures optimal temperature control, reducing the risk of overheating during prolonged operations. This cooling method enhances the motor’s lifespan and maintains consistent performance, even in demanding environments.

Automatic Tool Changer (ATC)

One of the most significant features of this CNC spindle motor is the Automatic Tool Changer (ATC). The ATC system allows for quick and seamless tool changes without manual intervention, significantly reducing downtime and increasing productivity. This feature is especially beneficial in high-volume production settings where efficiency is paramount.

Precision and Stability

The 4.5KW ATC Water Cooled Spindle Motor is engineered for precision, offering minimal runout and high stability. This accuracy is crucial for applications that require fine detail and exact tolerances, ensuring that every operation meets the required specifications.

Benefits of Using a 4.5KW ATC Water Cooled Spindle Motor

Implementing a 4.5KW ATC Water Cooled Spindle Motor in your CNC machine brings several advantages:

Increased Productivity

The combination of high power, efficient cooling, and the ATC system translates to increased productivity. Operators can perform multiple operations without stopping to change tools manually, streamlining the manufacturing process.

Enhanced Quality

The precision and stability of this CNC spindle motor ensure high-quality finishes and accurate cuts, reducing the likelihood of errors and rework. This improvement in quality can lead to cost savings and higher customer satisfaction.

Longevity and Reliability

The water-cooled spindle design and robust construction of the 4.5KW ATC spindle motor enhance its durability and reliability. The motor can operate continuously for long periods without performance degradation, making it a cost-effective investment for industrial applications.

Applications of the 4.5KW ATC Water Cooled Spindle Motor Automatic Tool Changer

This spindle motor is versatile and suitable for a wide range of applications, including:

CNC Machining Centers

In CNC machining centers, the 4.5KW ATC Water Cooled Spindle Motor is ideal for tasks such as milling, drilling, and engraving. Its high precision and power make it suitable for both large-scale industrial operations and small-scale custom projects.

Woodworking

For woodworking applications, this CNC spindle motor provides the speed and accuracy needed for intricate designs and detailed carvings. The ATC system is particularly useful for changing between different cutting tools, enhancing workflow efficiency.

Metalworking

In metalworking, the 4.5KW ATC Water Cooled Spindle Motor can handle various metals, providing clean and precise cuts. The cooling system ensures that the motor remains at an optimal temperature, even when working with tough materials.

Conclusion of 4.5KW ATC Water Cooled Spindle Motor Automatic Tool Changer

The 4.5KW ATC Water Cooled Spindle Motor Automatic Tool Changer is a powerful and versatile tool that brings numerous benefits to CNC machining and other industrial applications. Its advanced features, including the efficient cooling system and ATC capability, make it a valuable asset for enhancing productivity, quality, and reliability.

By integrating this spindle motor into your operations, you can achieve higher efficiency and precision, ensuring that your manufacturing processes meet the highest standards. Whether you are involved in woodworking, metalworking, or other CNC applications, the 4.5KW ATC Water Cooled Spindle Motor is an investment that can significantly improve your operational capabilities.