4.5KW ATC CNC Spindle Air Cooled Cooling Spindle Moter ISO30

Description

4.5KW ATC CNC Spindle Air Cooled Cooling Spindle Motor ISO30

4.5KW ATC CNC Spindle Air Cooled Cooling Spindle Moter ISO30 is a high-performance tool designed for advanced CNC machinery. This motor is engineered to provide efficient and reliable performance, making it a preferred choice for a wide range of industrial applications.

Introduction to the 4.5KW ATC CNC Spindle Air Cooled Cooling Spindle Motor ISO30

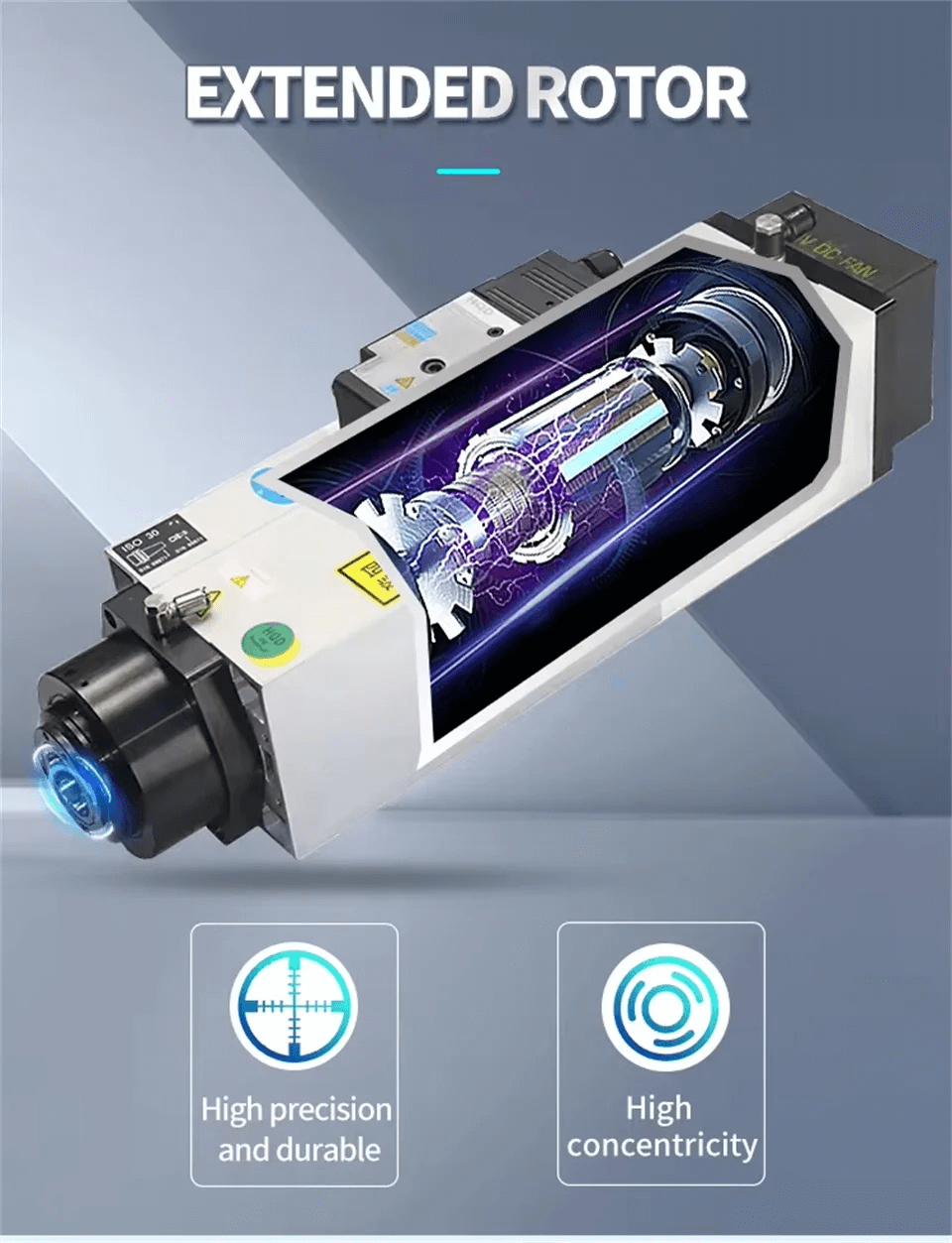

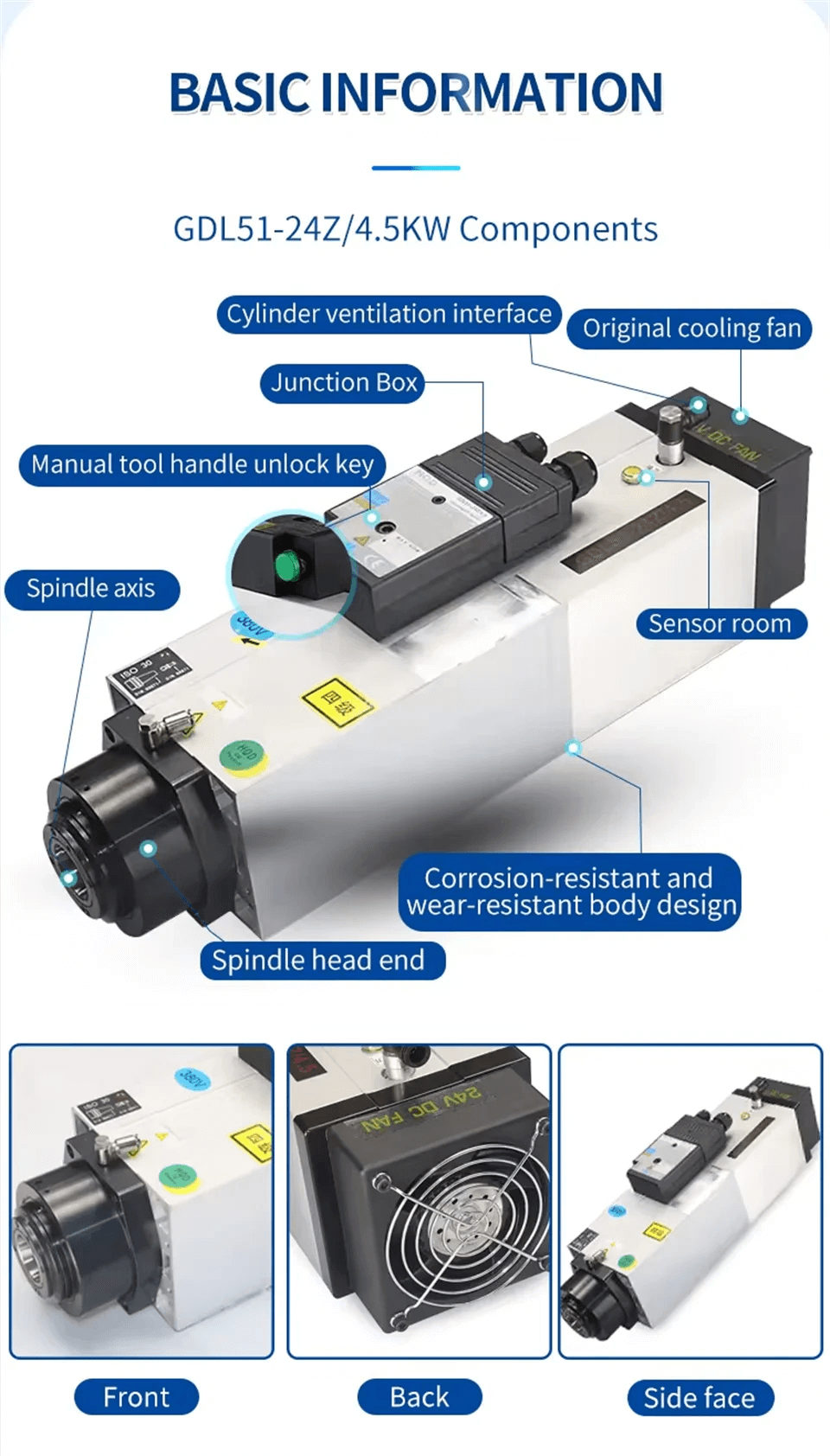

The 4.5KW ATC CNC spindle is a vital component in CNC machinery, known for its durability and precision. This spindle motor is equipped with an Automatic Tool Changer (ATC), which significantly enhances the efficiency of CNC operations by allowing for quick and seamless tool changes. The ISO30 tool holder compatibility ensures a wide range of tooling options, making it versatile for various machining tasks.

Features of the 4.5KW ATC CNC Spindle Air Cooled Cooling Spindle Motor ISO30

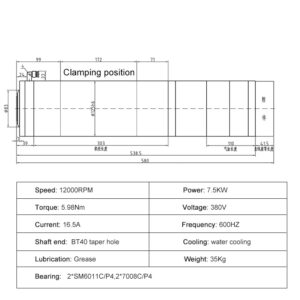

Brand: HQD

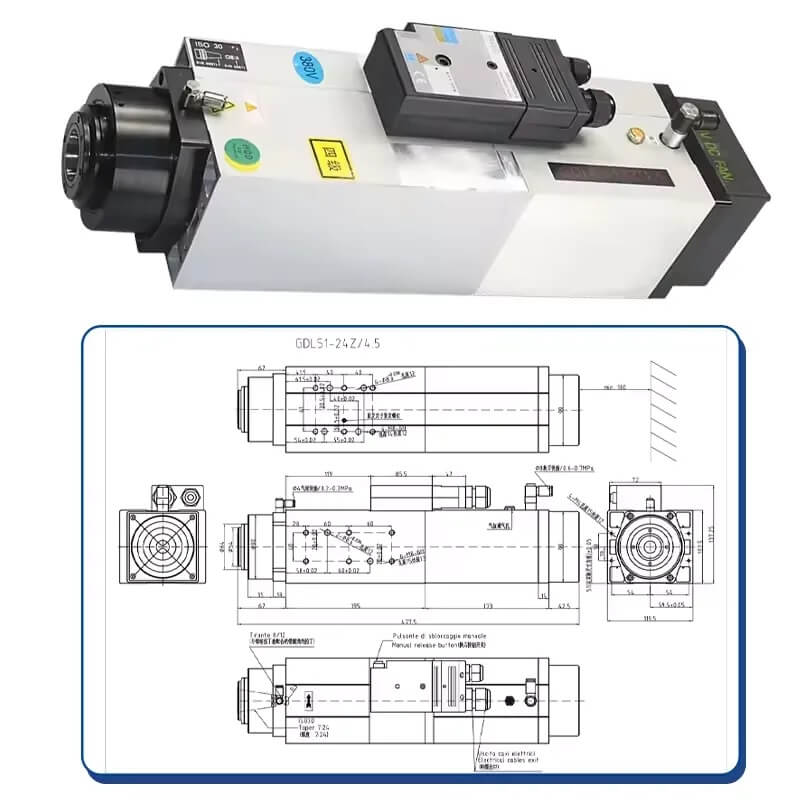

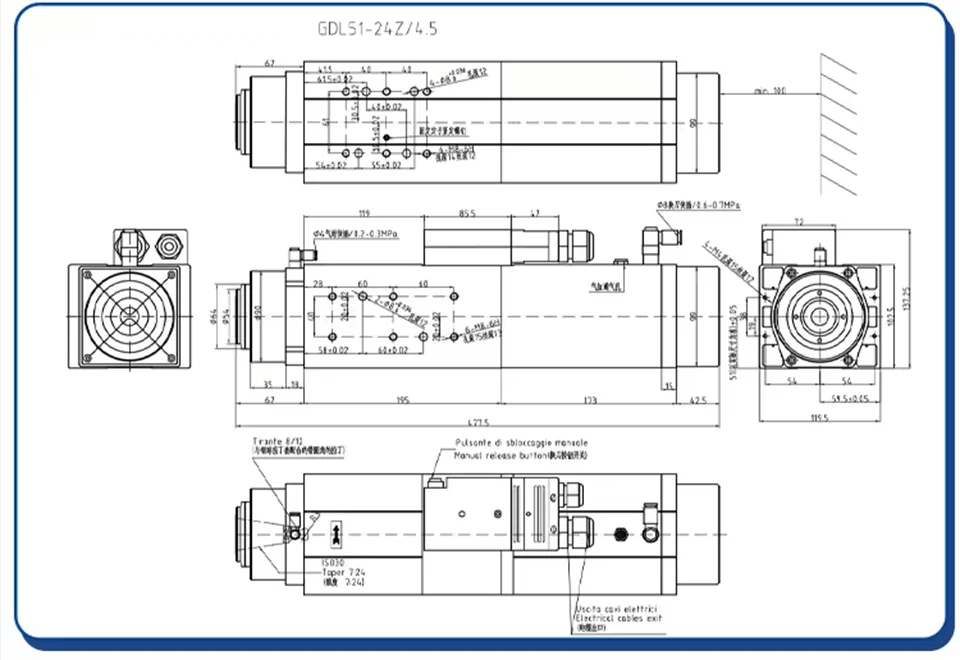

Model: GDL51-24Z/4.5

Power: 4.5KW

Current: 16.0/9.0A

Tool holder: ISO30

Number of poles: 4P

Bearing: 7008C*2pcs 7006C*2pcs

Rotating speed: 12000-24000rpm

Frequency: 400-800Hz

Voltage: 220v/380v

Cooling method: Fan cooling

Lubrication method: Grease lubrication

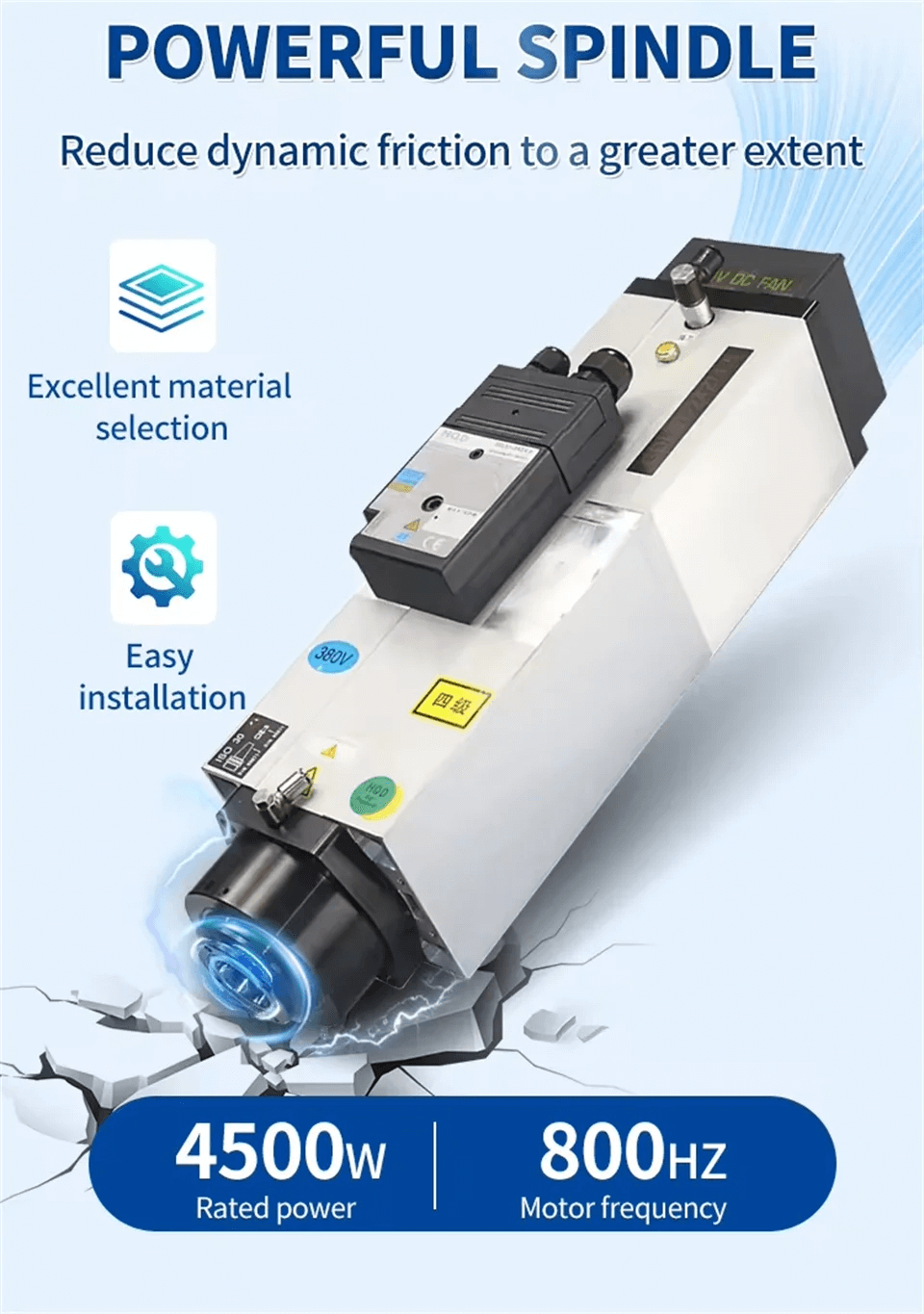

High Power and Performance

With a robust 4.5KW power output, this spindle motor is capable of handling demanding machining tasks with ease. Its high-speed operation ensures smooth and precise cutting, drilling, and milling, making it ideal for both wood and metalworking applications.

Air-Cooled System

The air-cooled design of this spindle motor offers several advantages. It eliminates the need for a liquid cooling system, reducing maintenance and operational costs. The efficient cooling mechanism ensures that the motor operates at optimal temperatures, thereby extending its lifespan and ensuring consistent performance.

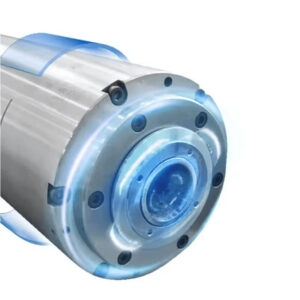

ISO30 Tool Holder

The ISO30 tool holder compatibility provides flexibility in tooling options. This standard tool holder is widely used in the industry, allowing for easy integration and interchangeability with existing CNC machinery. The ATC functionality further enhances the versatility of this spindle motor, enabling quick tool changes and minimizing downtime.

Applications of the 4.5KW ATC CNC Spindle Air Cooled Cooling Spindle Moter ISO30

Woodworking

In the woodworking industry, the 4.5KW ATC CNC spindle is invaluable for tasks such as cutting, engraving, and drilling. Its high-speed operation and precision make it perfect for creating intricate designs and patterns on wood surfaces.

Plastics and Composites

The versatility of the 4.5KW ATC CNC spindle extends to machining plastics and composite materials. Its precision and reliability make it suitable for producing high-quality parts and components from these materials.

Advantages of Choosing a 4.5KW Air-Cooled CNC Spindle

Reduced Maintenance

The air-cooled design of this spindle motor reduces the complexity of the cooling system, thereby minimizing maintenance requirements. This results in lower operational costs and less downtime for maintenance activities.

Enhanced Efficiency

The ATC functionality of the spindle motor significantly enhances the efficiency of CNC operations. By allowing for quick and automatic tool changes, it reduces cycle times and increases productivity.

Longevity and Reliability

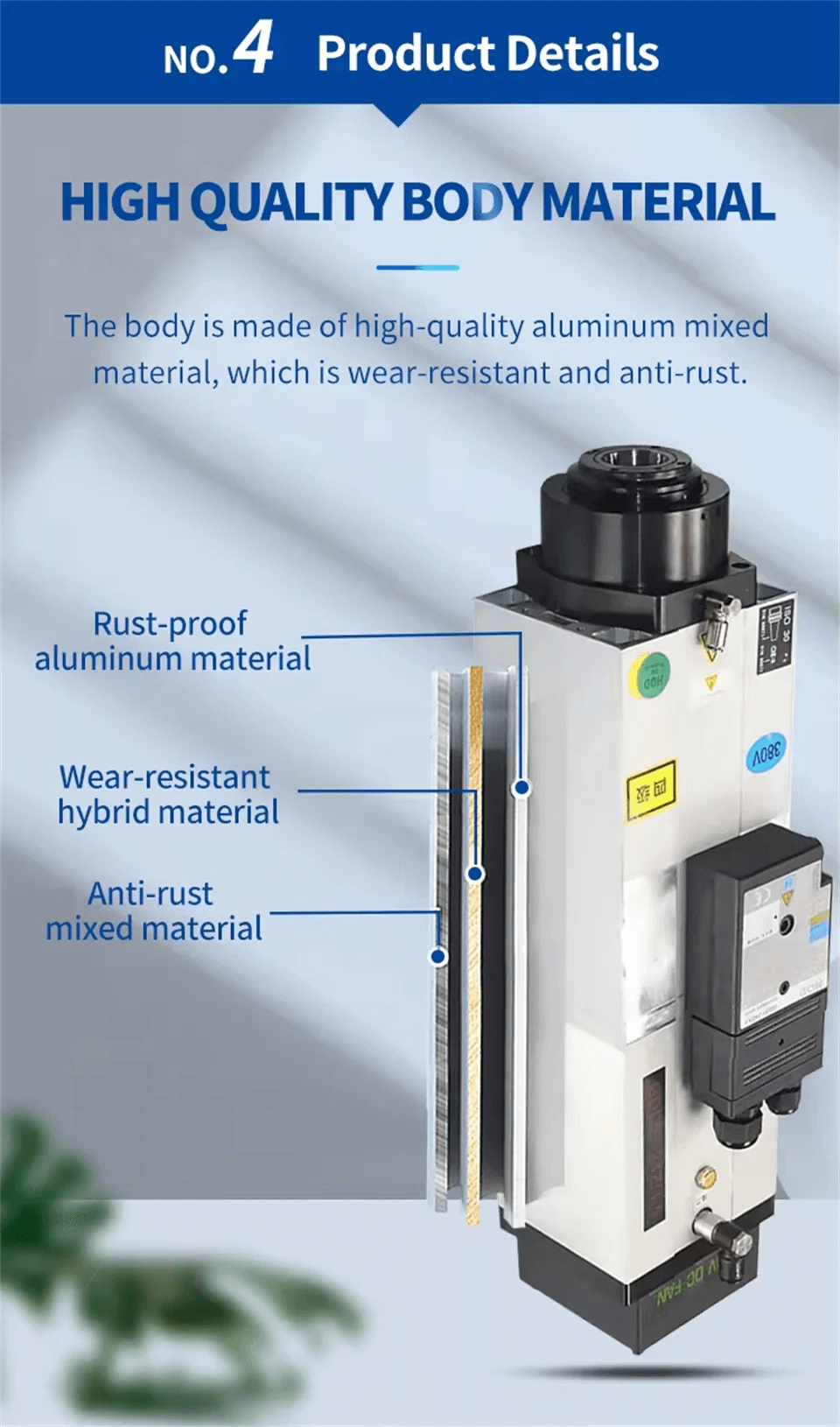

Built with high-quality materials and advanced engineering, the 4.5KW ATC CNC spindle is designed for long-term reliability. Its robust construction ensures that it can withstand the rigors of continuous operation in industrial environments.

Conclusion of 4.5KW ATC CNC Spindle Air Cooled Cooling Spindle Moter ISO30

The 4.5KW ATC CNC spindle air-cooled cooling spindle motor ISO30 is an excellent choice for industries seeking a powerful, efficient, and reliable spindle motor. Its combination of high power output, air-cooled system, and ATC functionality makes it suitable for a wide range of applications, from woodworking to metalworking and beyond. By investing in this advanced spindle motor, businesses can enhance their CNC operations, improve productivity, and reduce maintenance costs.