3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30

Description

3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30

The 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30 is designed to provide high precision and efficiency for machining various non-metal materials. With advanced features and robust construction, this spindle motor is ideal for professional CNC machining tasks.

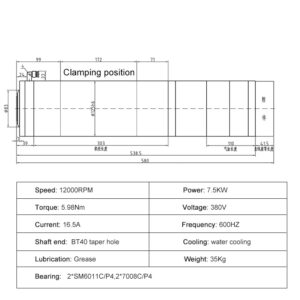

Technical Specifications

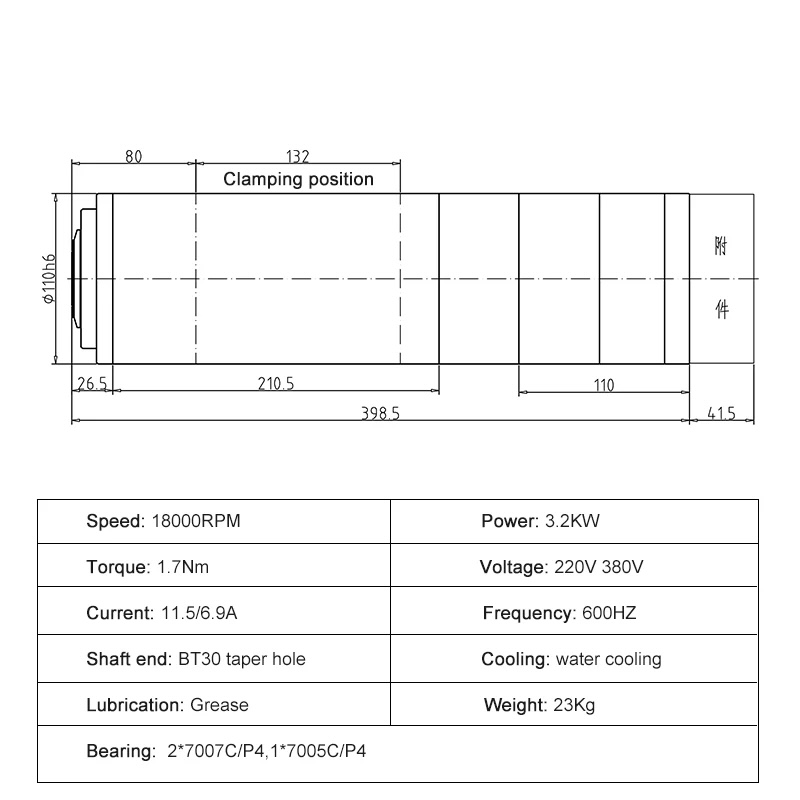

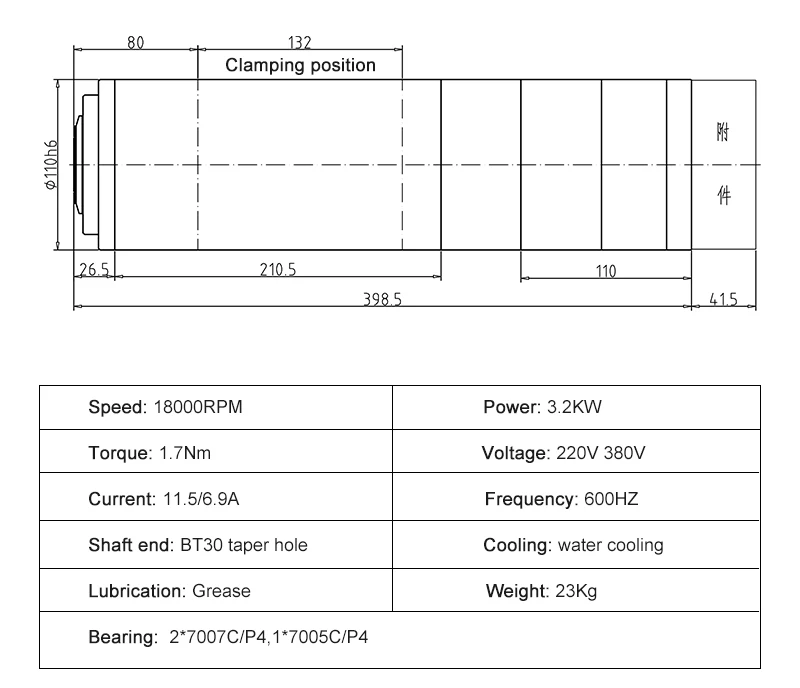

Model: GDL110-30-18Z/3.2

Diameter: 110 mm

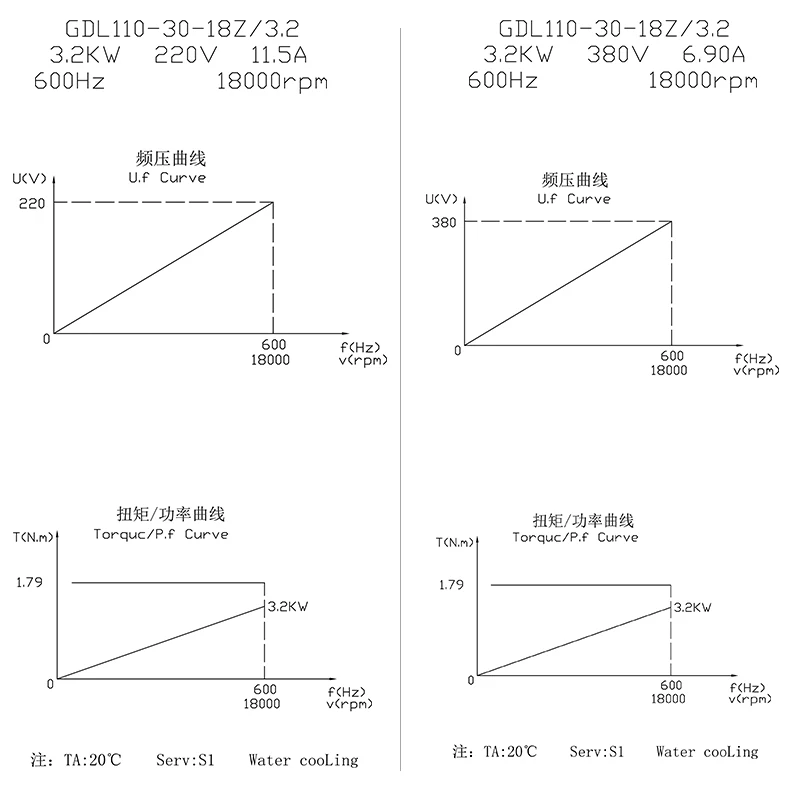

Speed Regulation: Utilizes a three-phase output inverter to adjust the spindle speed by changing the frequency

Cooling Method: Water cooling

Power: 3.2 kW

Voltage: 220V/380V

Current: 11.5A (220V) / 6.5A (380V)

Frequency: 600 Hz

Speed: 18,000 RPM

Number of Poles: 4

Phase: 3-phase asynchronous driver

Rotation: Counterclockwise (viewed from the shaft end)

Tool Handle: BT30 ER32

Pull Stud: BT30-45°

Lubrication: Grease

Main Uses: Carving wood, bamboo, PCB, PVC, PMMA, plastic, ABS, and other non-metals

Connection and Installation Instructions for 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30

- Power Cord Connections:

- Three-color wires: Connect to U, V, W phases

- Yellow-green wire: Connect to ground

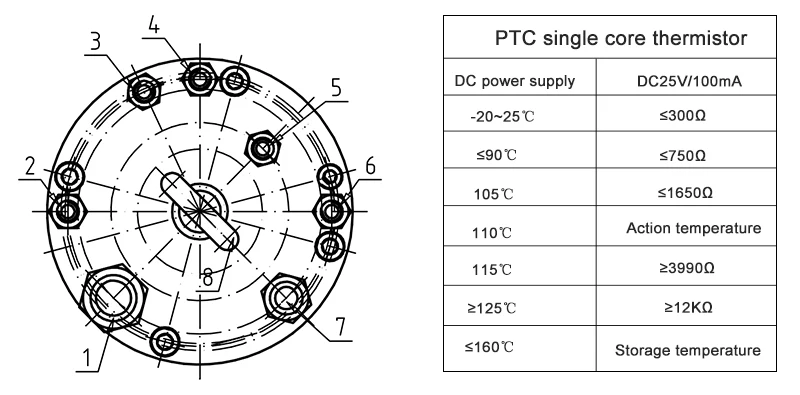

- Temperature control line: 110℃ thermistor two-phase connected to temperature control protector

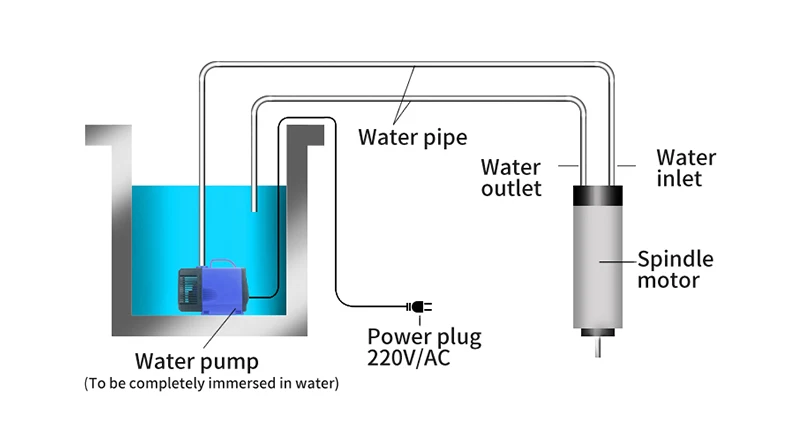

- Cooling Water Outlet:

- Connect 8/6 hose to end points 2 and 6

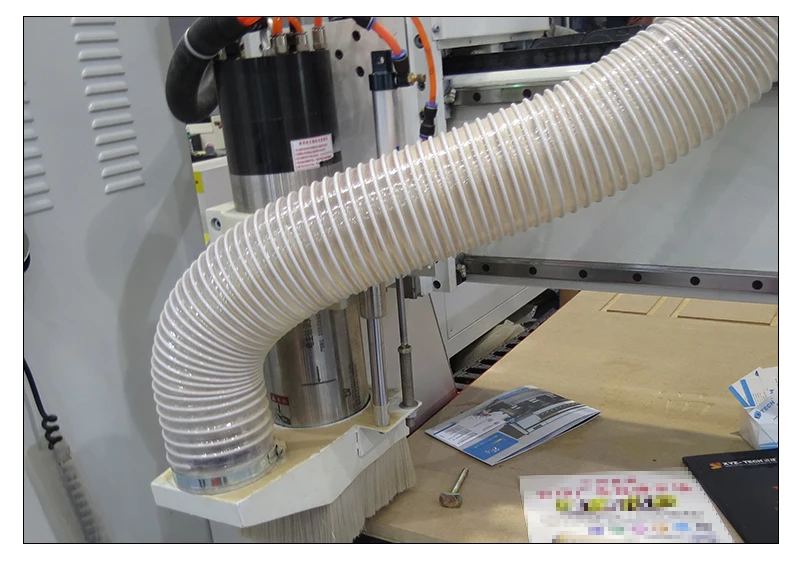

- Knife Change and Dust Removal Pressure:

- Maintain at 0.2 MPa using 6/4 hose

- Air Seal Pressure:

- Maintain at 0.1 MPa using 6/4 hose

- Unloader Inlet Pressure:

- Maintain at 0.70 MPa using 6/4 hose

- Cooling Water Inlet:

- Ensure pump head is at 12m (important: connect correctly!)

- Proximity Switches:

- Two NPN (normally open) proximity switches for hanging and unloading knives

- Connection: Brown wire to +24VDC, Blue wire to 0VDC, Signal load connected to +24VDC on one end, Black wire on the other end

- Ring Handle:

- For installation and use

Key Features of 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30

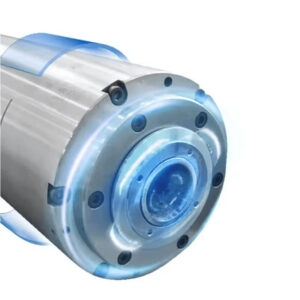

- Double Sealing and Air Sealing Structure:

- The 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30 boasts a unique double sealing air seal structure that significantly improves dustproof and waterproof performance, making it suitable for processing materials such as copper, aluminum, steel, and stone.

- BT30 Taper Holes:

- The spindle ends are connected with standard BT30 taper holes. The 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30 utilizes 4 high-precision P4 bearings, ensuring operational and machining accuracy.

Operational Guidelines for 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30

- Working Environment Temperature:

- This spindle motor operates optimally within a temperature range of -10℃ to 40℃.

- Initial Setup:

- Before installation, manually rotate the spindle head to check for smooth operation and absence of blockages.

Bearing Specifications

- P4 Fully Sealed Angular Contact Ceramic Bearings:

- These bearings extend the service life of the spindle and are designed for high temperatures and low friction. They provide low noise and increased longevity, ensuring the 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30 operates smoothly and efficiently.

- Temperature and Friction Resistance:

- Ceramic ball bearings are highly resistant to high temperatures and produce low heat, making them ideal for the demanding operations of the 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30.

Usage Precautions for 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30

- Water Pump Requirement:

- Always use the spindle with a water pump to prevent overheating and damage.

- Inverter Compatibility:

- Ensure the power of the inverter matches or exceeds the spindle’s power. Correctly set the inverter parameters before use to prevent immediate damage to both the spindle and the inverter.

- Noise Monitoring:

- If you notice unusual noise, stop the spindle immediately and check for bearing replacement needs.

By adhering to these guidelines and operational instructions, you can ensure that the 3.2KW Automatic Tool Change Water Cooled Spindle Motor BT30 provides precise and efficient machining for various non-metal materials, enhancing your CNC machining capabilities.