3.0kw ER20 Air-Cooled Spindle Motor 4 Bearings Square Flange

Description

3.0kw ER20 Air-Cooled Spindle Motor 4 Bearings Square Flange

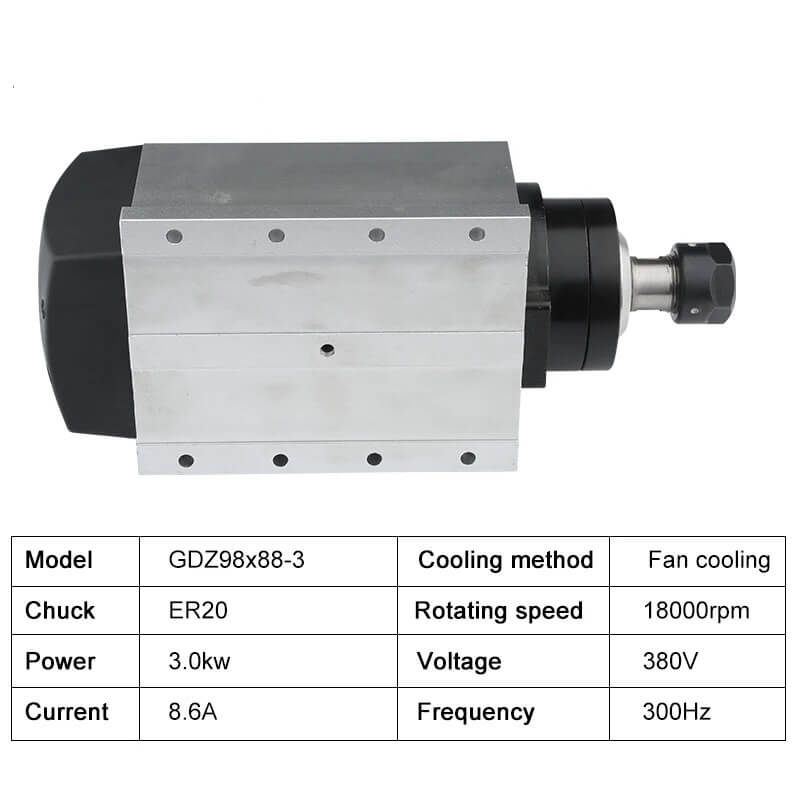

The CNC Spindle Basic Parameter

- Model: GDF46-18Z/2.2

- Power: 2.2KW

- Chuck: ER20

- Cooling: Air Cooled

- Rotating Speed: 18000rpm

- Electric Current: 4.4A/7.8A

- Spindle Frequency: 300Hz

- Lubrication Method: Grease Lubrication

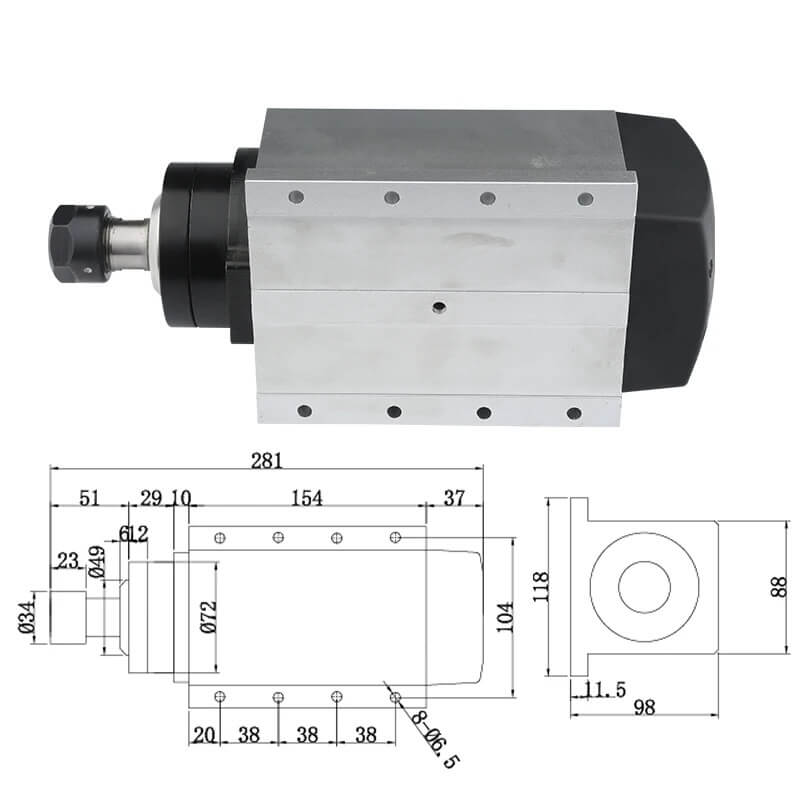

Parameters of the 3.0kw ER20 Air-Cooled Spindle Motor

The 3.0kw ER20 air-cooled spindle motor with a square flange is designed for high-performance machining tasks. Here are its key parameters:

– Power Output:3.0kw, providing robust power for demanding applications.

– Speed:Capable of achieving speeds up to 24,000 RPM for high-efficiency cutting and engraving.

– Collet Size:ER20, accommodating a variety of tool sizes for versatile machining.

– Cooling System:Air-cooled design for straightforward maintenance and reliable operation.

– Bearings:Equipped with 4 high-quality bearings to ensure smooth and stable performance.

– Mounting:Square flange design for easy and secure mounting on various CNC machines.

Applications of the 3.0kw ER20 Air-Cooled Spindle Motor

This powerful spindle motor is suitable for a wide range of CNC applications, including:

– Woodworking:Perfect for CNC routers used in carving, cutting, and shaping wood materials.

– Metalworking:Suitable for machining non-ferrous metals like aluminum and brass with precision.

– Plastics and Composites:Efficient in cutting and engraving plastic materials and composites.

– Sign Making:Ideal for creating detailed signs and displays from various materials.

– Prototyping:Essential for rapid prototyping, providing the speed and accuracy needed for detailed models.

Industry and Materials for the 3.0kw ER20 Air-Cooled Spindle Motor

The 3.0kw ER20 air-cooled spindle motor with 4 bearings and a square flange is used across multiple industries due to its versatility and reliability:

– Manufacturing:Enhances productivity in manufacturing by delivering consistent performance.

– Automotive:Used in machining automotive parts, molds, and prototypes.

– Aerospace: Beneficial in aerospace applications for machining lightweight metals and composites.

– Furniture:Used in the furniture industry for precise cutting and shaping of wood and MDF.

– Signage:Essential in the signage industry for engraving and cutting materials like acrylic and aluminum.

The materials suitable for machining with this spindle motor include:

– Wood:Softwoods and hardwoods.

– Metals:Aluminum, brass, and other non-ferrous metals.

– Plastics:Acrylic, polycarbonate, and other common plastics.

– Composites:Fiberglass, carbon fiber, and other composite materials.

In summary, the 3.0kw ER20 air-cooled spindle motor with 4 bearings and a square flange is a powerful and versatile tool, essential for various industrial applications. Its robust design ensures high performance and longevity, making it a critical component in modern CNC machining.