China grootste CNC-spillengroothandel, biedt allerlei soorten cnc-spindels voor houtsnijwerk, metaalfrezen, steenhouwen enzovoort. Bied een spindel van hogere kwaliteit met snelle levering over de hele wereld.

Precisie en efficiëntie CNC-freesspindelmotor voor CNC-machines

Een betrouwbare spindel is het hart van elke CNC-freesmachine. De juiste spindelmotor voor uw CNC-freesmachine zorgt voor precisie, duurzaamheid en een soepele werking.

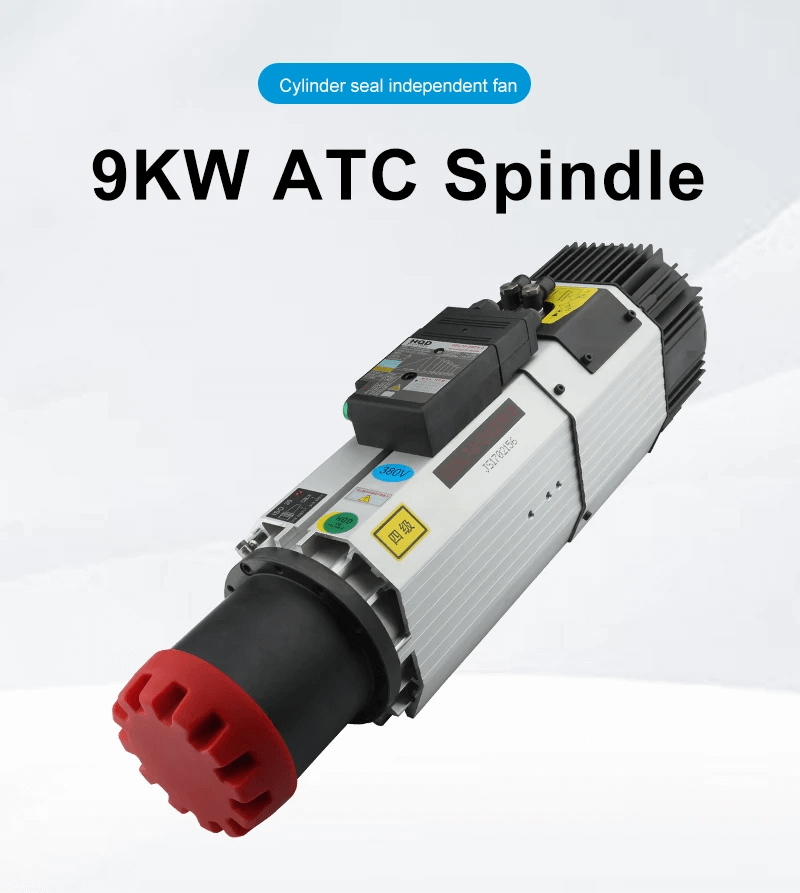

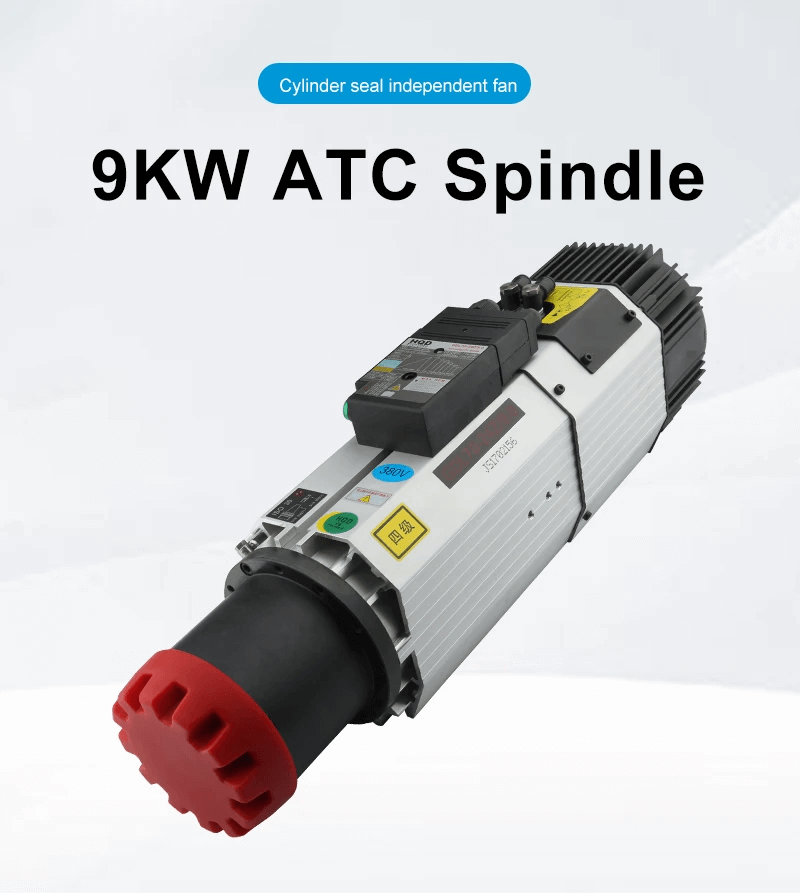

ATC-spindelmotor 9 kW – Hoogwaardige CNC-freesspindel

Een betrouwbare spindel is het hart van elke CNC-freesmachine. De ATC-spindelmotor uit de HQD-spindelmotorserie biedt precisie, duurzaamheid en hoge snelheidsprestaties voor houtbewerking, metaalbewerking en andere industriële toepassingen.

Spilmotoren voor boren: de 9 kW luchtgekoelde hogesnelheidsoplossing

In de wereld van CNC-bewerking en metaalbewerking is het selecteren van de juiste spindelmotor cruciaal voor efficiëntie, nauwkeurigheid en duurzaamheid.

Luchtgekoelde spindelmotoren: de 9 kW hogesnelheids CNC-freesspindelmotor

Bij CNC-bewerking is de spindelmotor het hart van de machine. Deze bepaalt de kwaliteit, snelheid en precisie van het snijproces.

BT30-spindelmotor, CNC-draaibankspindelmotor en ATC-spindelmotor

In de wereld van CNC-bewerking is de spindelmotor een van de belangrijkste componenten die de prestaties, precisie en betrouwbaarheid van de machine bepaalt.

Router ATC-spindel: verbeter uw CNC-freesmachine met automatische gereedschapswisseling

Een onderdeel dat de mogelijkheden van CNC-freesmachines aanzienlijk verbetert, is de ATC-spil (Automatic Tool Changer).