중국 최대 CNC 스핀들 도매, 나무 조각, 금속 밀링, 석재 조각 등에 대한 모든 종류의 CNC 스핀들을 제공합니다. 전 세계에 빠른 배송으로 더 높은 품질의 스핀들을 제공합니다.

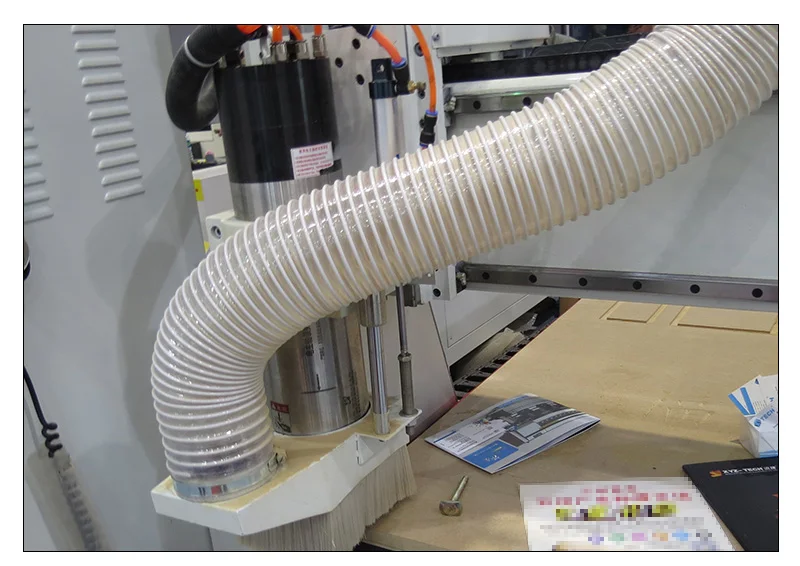

CNC 기계용 정밀하고 효율적인 CNC 라우터 스핀들 모터

신뢰할 수 있는 스핀들은 모든 CNC 라우터의 핵심이며, 올바른 CNC 라우터 스핀들 모터는 정밀성, 내구성 및 원활한 작동을 보장합니다.

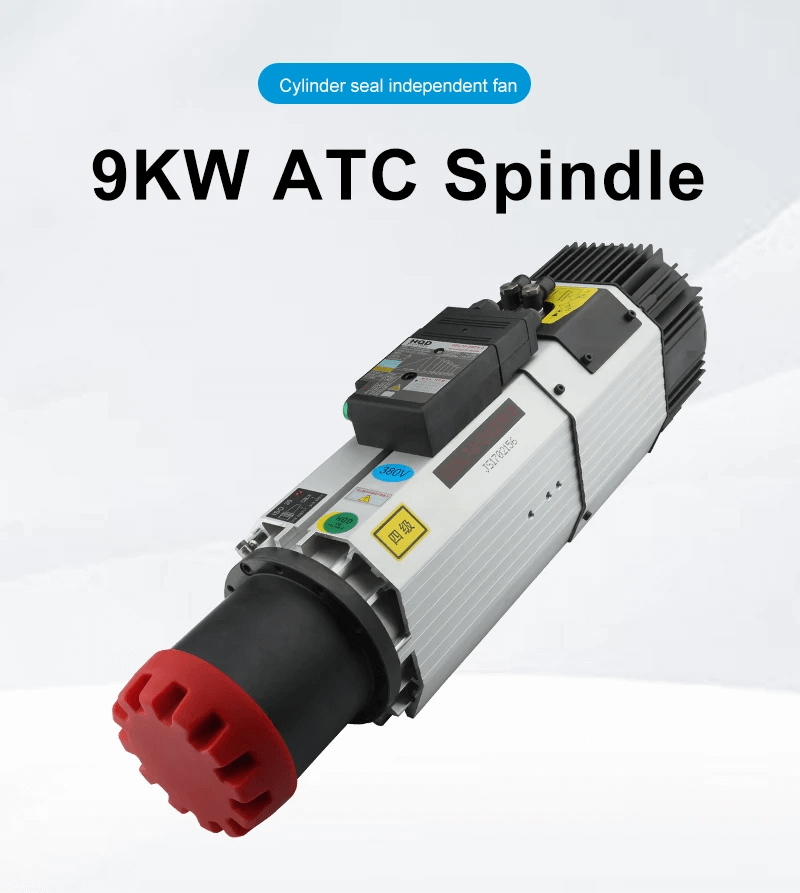

ATC 스핀들 모터 9kW – 고성능 CNC 라우터 스핀들

신뢰할 수 있는 스핀들은 모든 CNC 라우터의 핵심이며, ATC 스핀들 모터 HQD 스핀들 모터 시리즈는 목공, 금속 가공 및 기타 산업용 응용 분야에 정밀성, 내구성 및 고속 성능을 제공합니다.

드릴링용 스핀들 모터: 9kW 공랭식 고속 솔루션

CNC 가공 및 금속 가공 분야에서는 효율성, 정확성, 내구성을 위해 올바른 스핀들 모터를 선택하는 것이 매우 중요합니다.

공랭식 스핀들 모터: 9kW 고속 CNC 라우터 스핀들 모터

CNC 가공에서 스핀들 모터는 기계의 핵심입니다. 절삭 공정의 품질, 속도, 그리고 정밀도를 결정합니다.

BT30 스핀들 모터, CNC 선반 스핀들 모터 및 ATC 스핀들 모터

CNC 가공 분야에서 스핀들 모터는 기계 성능, 정밀도, 안정성을 결정하는 가장 중요한 구성 요소 중 하나입니다.

라우터 ATC 스핀들: 자동 공구 교환으로 CNC 라우터 성능 향상

CNC 라우터의 성능을 획기적으로 향상시키는 구성 요소 중 하나는 ATC(자동 공구 교환기) 스핀들입니다.