中国最大の CNC スピンドル卸売業者。木彫り、金属フライス加工、石彫りなどに使用するあらゆる種類の CNC スピンドルを提供しています。世界中に迅速に配送し、高品質のスピンドルを提供しています。

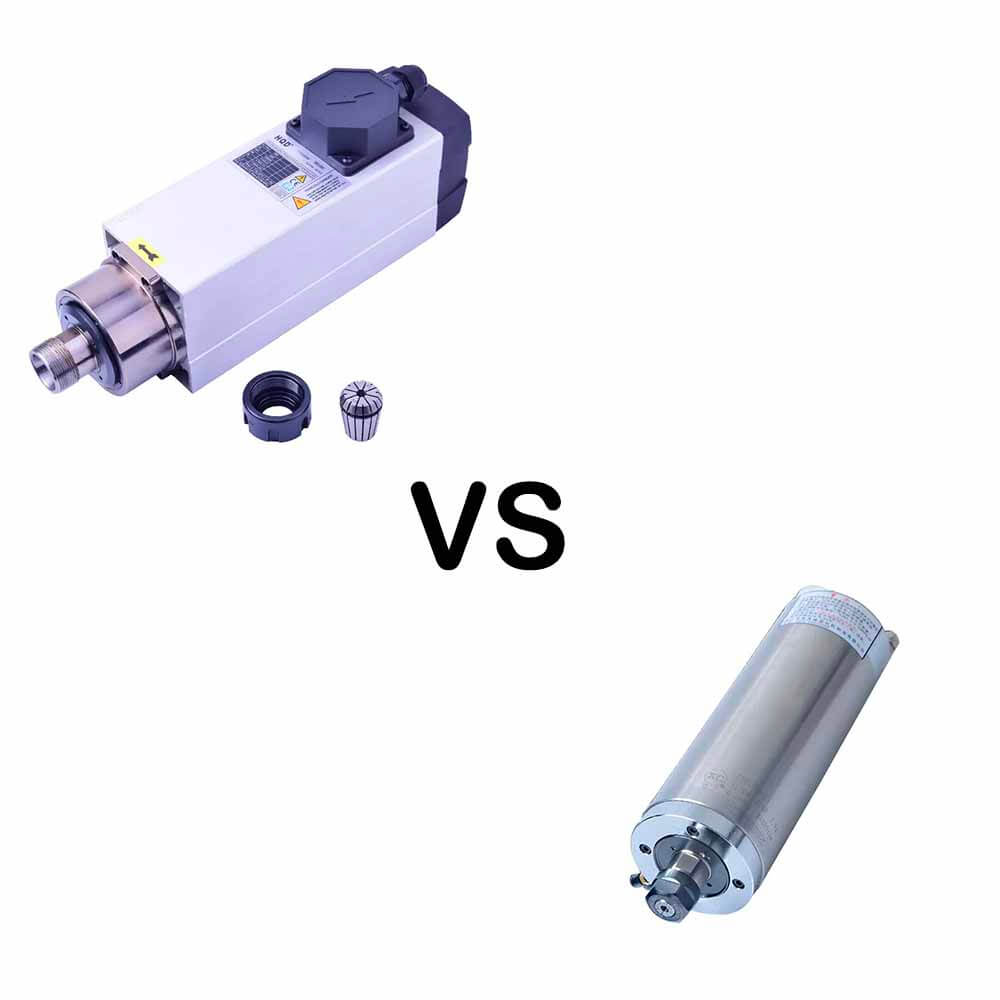

CNCルータースピンドルモーター:空冷式と水冷式

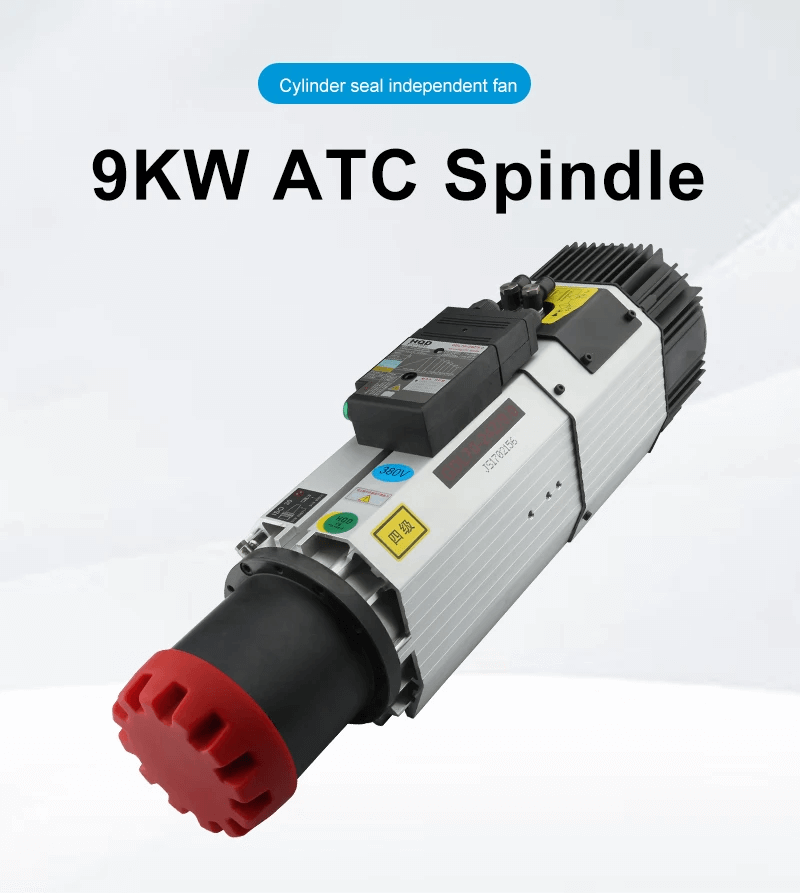

CNC マシンをアップグレードしてパフォーマンス、速度、自動化を向上させることをお考えの場合は、自動工具交換装置 (ATC) を備えた CNC スピンドルに投資すると大きな効果が得られます。

CNCルーター用高性能2.2kW水冷ATCスピンドル JGL-80 2.2R30-20

プロフェッショナルにとっても愛好家にとっても、スピンドルモーター ATC (自動工具交換装置) システムに投資することで、ワークフローを劇的に改善することができます。

最適なCNC ATCスピンドルを見つける - eBayからColombo Precisionまで

CNC マシンをアップグレードしてパフォーマンス、速度、自動化を向上させることをお考えの場合は、自動工具交換装置 (ATC) を備えた CNC スピンドルに投資すると大きな効果が得られます。