China biggest CNC Spindles Wholesale, Offer all kinds of cnc spindle for wood carving, metal milling, stone carving and so on. Offer higher quality spindle with Fast derlivery all over the worlds.

Precision and Efficiency CNC Router Spindle Motor for CNC Machines

A reliable spindle is the heart of any CNC router, and the right CNC router spindle motor ensures precision, durability, and smooth operation.

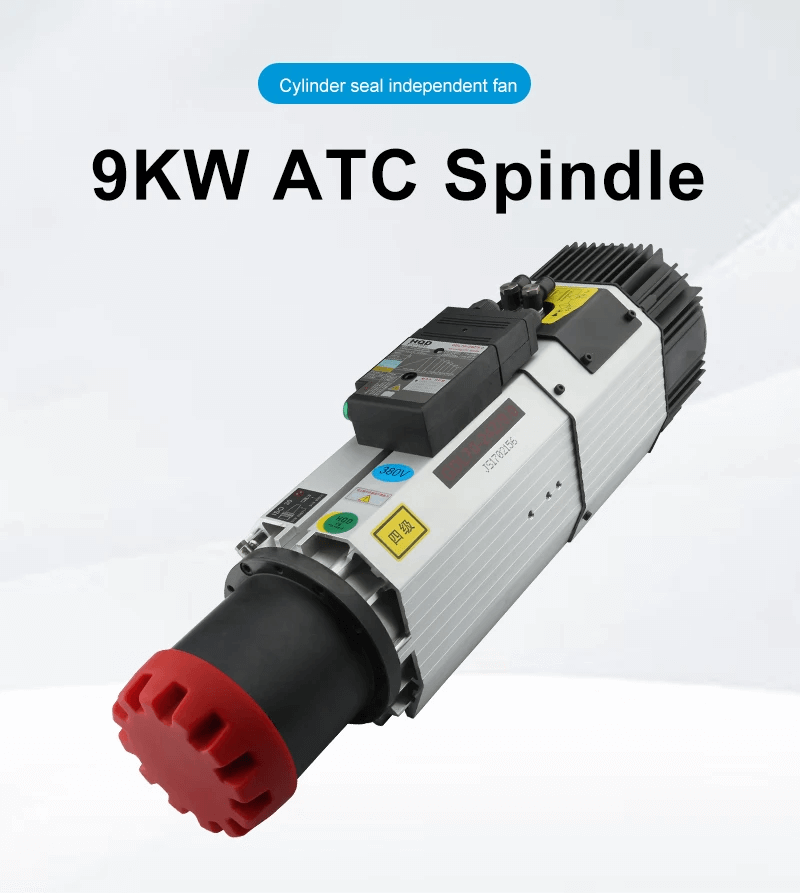

ATC Spindle Motor 9 kW – High-Performance CNC Router Spindle

A reliable spindle is the heart of any CNC router, and the ATC spindle motor HQD spindle motor series offers precision, durability, and high-speed performance for woodworking, metalworking, and other industrial applications.

Spindle Motors for Drilling: The 9kW Air Cooled High-Speed Solution

In the world of CNC machining and metalworking, selecting the right spindle motor is crucial for efficiency, accuracy, and durability.

Air Cooled Spindle Motors: The 9kW High Speed CNC Router Spindle Motor

In CNC machining, the spindle motor is the heart of the machine. It determines the quality, speed, and precision of the cutting process.

BT30 Spindle Motor, CNC Lathe Spindle Motor, and ATC Spindle Motor

In the world of CNC machining, the spindle motor is one of the most critical components that determines machine performance, precision, and reliability.

Router ATC Spindle: Boost Your CNC Router with Automatic Tool Changing

One component that dramatically improves CNC router capabilities is the ATC (Automatic Tool Changer) spindle.