Hiina suurim CNC-spindlite hulgimüük, pakub igasuguseid CNC-spindleid puidu nikerdamiseks, metalli freesimiseks, kivi nikerdamiseks ja nii edasi. Pakkuge kvaliteetsemat spindlit kiire kohaletoimetamisega kõikjal maailmas.

Täppis- ja efektiivsusega CNC-ruuteri spindlimootor CNC-masinatele

Usaldusväärne spindl on iga CNC-freespingi süda ja õige CNC-freespingi spindlimootor tagab täpsuse, vastupidavuse ja sujuva töö.

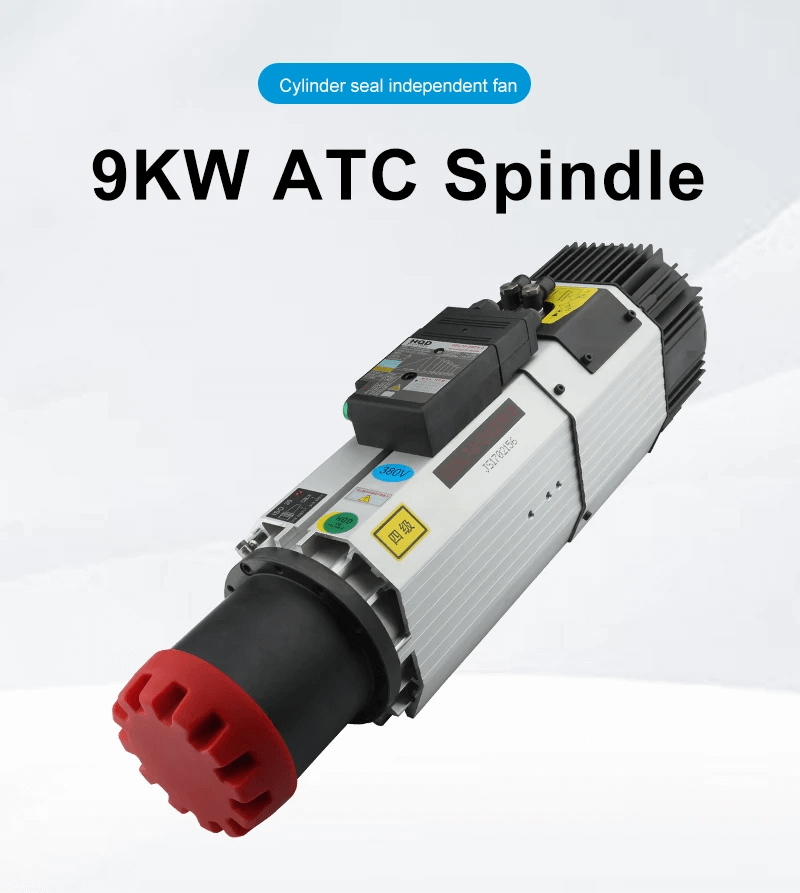

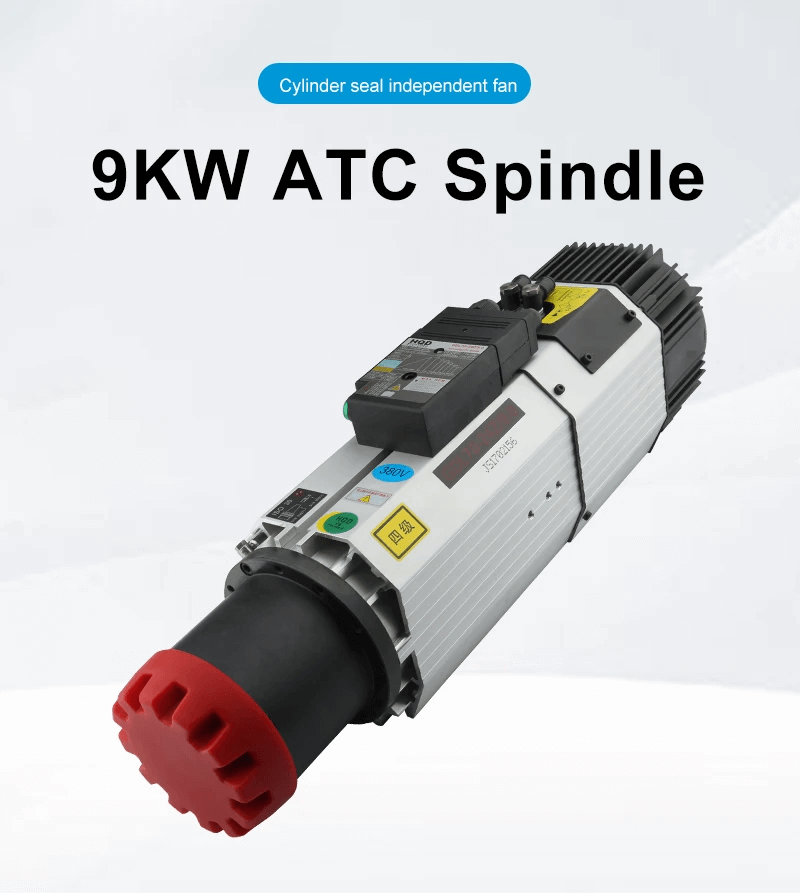

ATC spindlimootor 9 kW – suure jõudlusega CNC-freespink

Usaldusväärne spindl on iga CNC-freespingi süda ja ATC spindlimootori HQD spindlimootorite seeria pakub täpsust, vastupidavust ja kiiret jõudlust puidutöötlemiseks, metallitöötlemiseks ja muudeks tööstuslikeks rakendusteks.

Spindlimootorid puurimiseks: 9 kW õhkjahutusega kiire lahendus

CNC-töötlemise ja metallitöötlemise maailmas on õige spindlimootori valimine efektiivsuse, täpsuse ja vastupidavuse tagamiseks ülioluline.

Õhkjahutusega spindlimootorid: 9 kW kiire CNC-freespinki spindlimootor

CNC-töötluses on spindlimootor masina süda. See määrab lõikeprotsessi kvaliteedi, kiiruse ja täpsuse.

BT30 spindlimootor, CNC treipingi spindlimootor ja ATC spindlimootor

CNC-töötlemise maailmas on spindlimootor üks olulisemaid komponente, mis määrab masina jõudluse, täpsuse ja töökindluse.

Freesi ATC spindel: täiusta oma CNC-freeserit automaatse tööriistavahetusega

Üks komponent, mis CNC-freesi võimalusi märkimisväärselt parandab, on ATC (automaatse tööriistavahetaja) spindel.