Los husillos CNC más grandes de China al por mayor, ofrecen todo tipo de husillos CNC para tallado en madera, fresado de metales, tallado en piedra, etc. Ofrezca husillos de mayor calidad con entrega rápida en todo el mundo.

Motor de husillo de fresadora CNC de precisión y eficiencia para máquinas CNC

Un husillo confiable es el corazón de cualquier enrutador CNC, y el motor de husillo de enrutador CNC adecuado garantiza precisión, durabilidad y un funcionamiento suave.

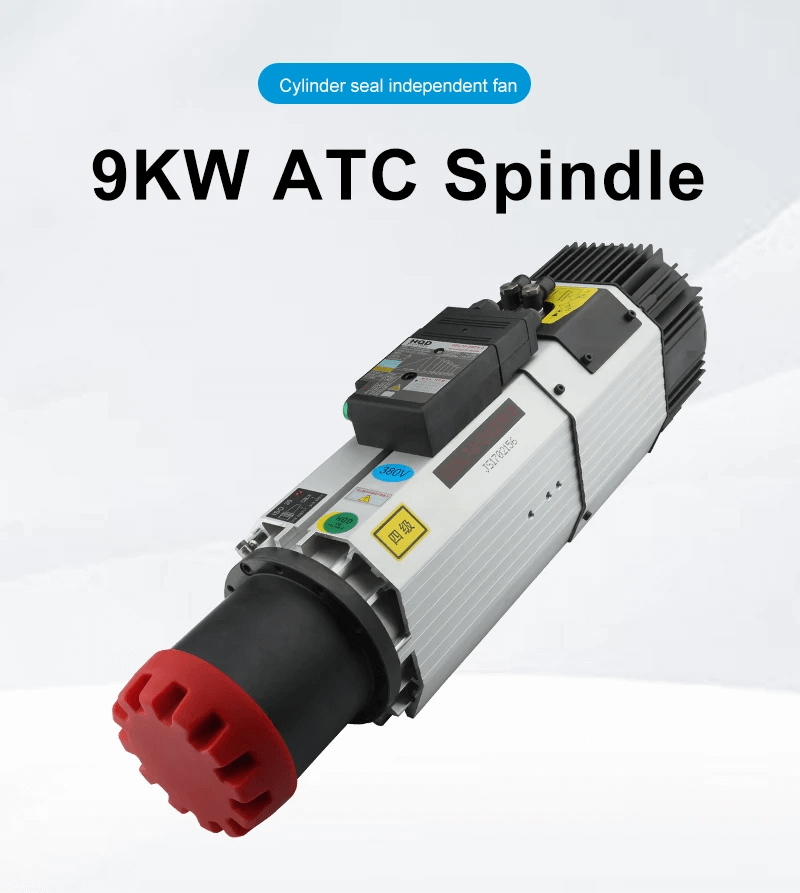

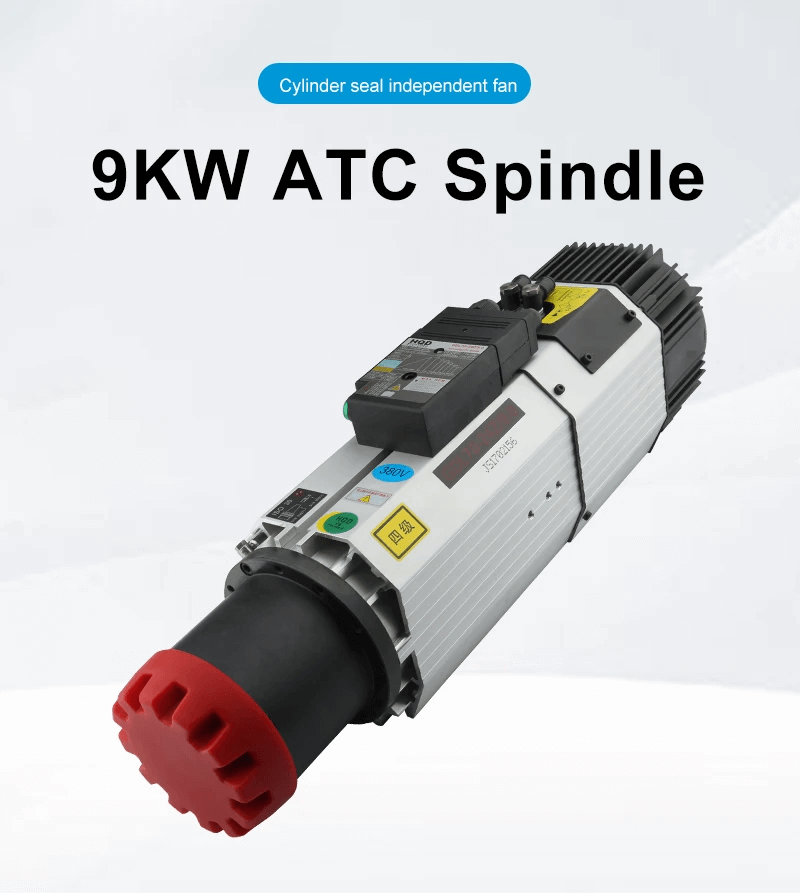

Motor de husillo ATC de 9 kW: husillo de fresadora CNC de alto rendimiento

Un husillo confiable es el corazón de cualquier enrutador CNC, y la serie de motores de husillo ATC HQD ofrece precisión, durabilidad y rendimiento de alta velocidad para trabajar la madera, el metal y otras aplicaciones industriales.

Motores de husillo para perforación: la solución de alta velocidad refrigerada por aire de 9 kW

En el mundo del mecanizado CNC y la metalurgia, seleccionar el motor de husillo adecuado es crucial para lograr eficiencia, precisión y durabilidad.

Motores de husillo refrigerados por aire: motor de husillo de fresadora CNC de alta velocidad de 9 kW

En el mecanizado CNC, el motor del husillo es el corazón de la máquina. Determina la calidad, la velocidad y la precisión del proceso de corte.

Motor de husillo BT30, motor de husillo de torno CNC y motor de husillo ATC

En el mundo del mecanizado CNC, el motor del husillo es uno de los componentes más críticos que determinan el rendimiento, la precisión y la confiabilidad de la máquina.

Husillo ATC para fresadora: potencie su fresadora CNC con cambio automático de herramientas

Un componente que mejora drásticamente las capacidades del enrutador CNC es el husillo ATC (cambiador automático de herramientas).