Chinas größter CNC-Spindelgroßhändler. Bietet alle Arten von CNC-Spindeln für Holzschnitzerei, Metallfräsen, Steinschnitzerei usw. Bietet Spindeln höherer Qualität mit schneller Lieferung in die ganze Welt.

Präziser und effizienter CNC-Frässpindelmotor für CNC-Maschinen

Eine zuverlässige Spindel ist das Herzstück jedes CNC-Fräsers und der richtige Spindelmotor des CNC-Fräsers sorgt für Präzision, Haltbarkeit und reibungslosen Betrieb.

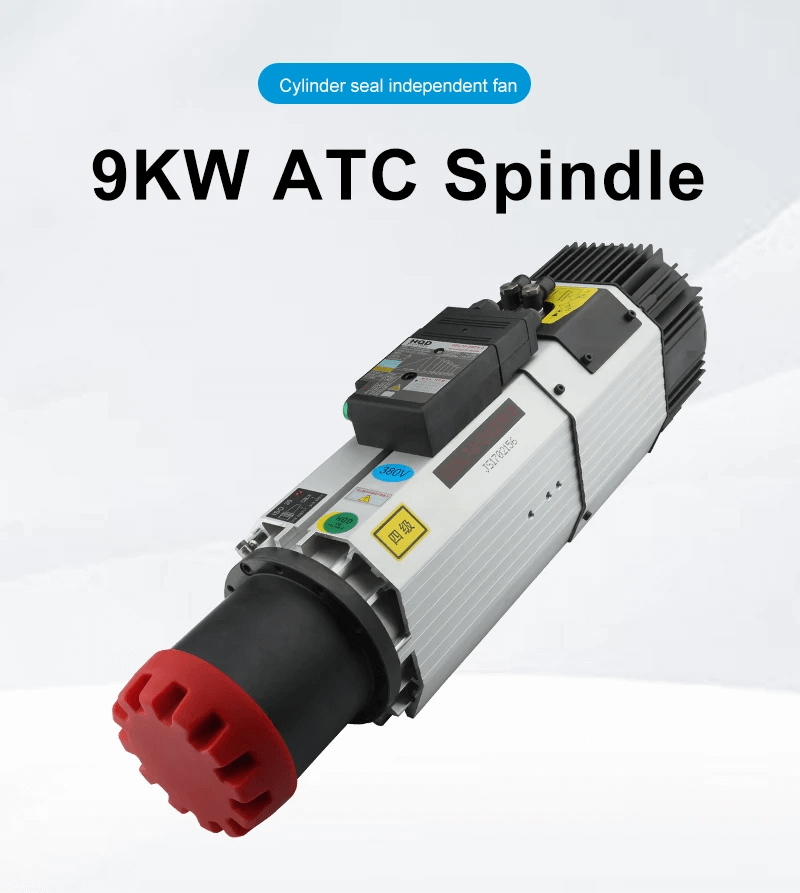

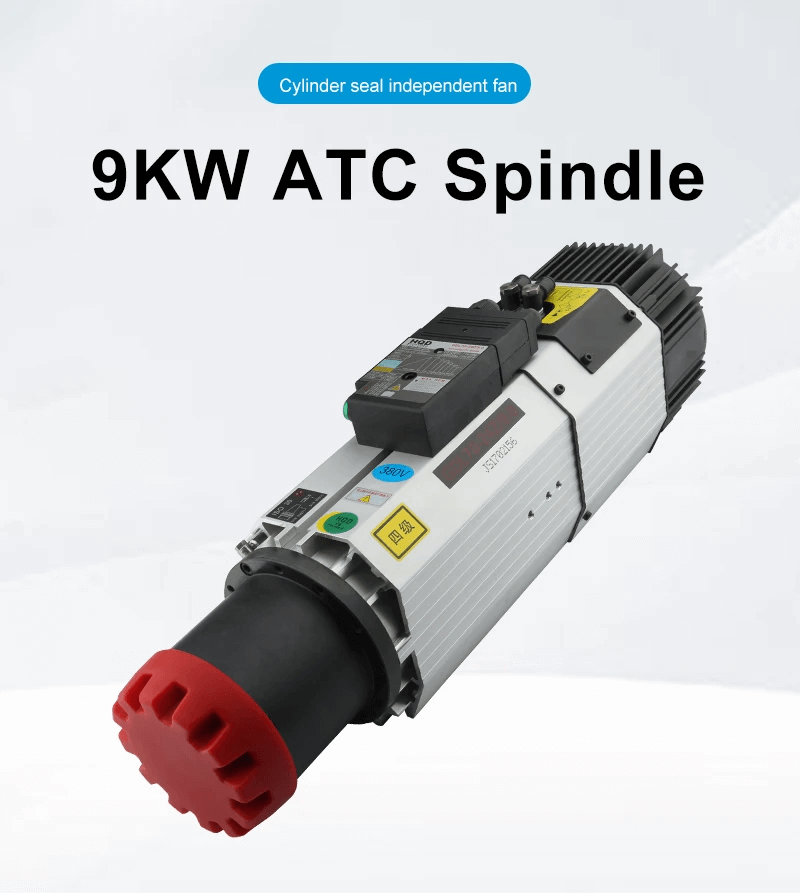

ATC Spindelmotor 9 kW – Hochleistungs-CNC-Frässpindel

Eine zuverlässige Spindel ist das Herzstück jedes CNC-Fräsers, und die Spindelmotoren der ATC-HQD-Serie bieten Präzision, Haltbarkeit und Hochgeschwindigkeitsleistung für die Holz- und Metallbearbeitung sowie andere industrielle Anwendungen.

Spindelmotoren zum Bohren: Die luftgekühlte 9-kW-Hochgeschwindigkeitslösung

In der Welt der CNC-Bearbeitung und Metallverarbeitung ist die Auswahl des richtigen Spindelmotors entscheidend für Effizienz, Genauigkeit und Haltbarkeit.

Luftgekühlte Spindelmotoren: Der 9-kW-Hochgeschwindigkeits-Spindelmotor für CNC-Fräser

Bei der CNC-Bearbeitung ist der Spindelmotor das Herzstück der Maschine. Er bestimmt die Qualität, Geschwindigkeit und Präzision des Schneidprozesses.

BT30-Spindelmotor, CNC-Drehmaschinen-Spindelmotor und ATC-Spindelmotor

In der Welt der CNC-Bearbeitung ist der Spindelmotor eine der wichtigsten Komponenten, die die Leistung, Präzision und Zuverlässigkeit der Maschine bestimmt.

Router-ATC-Spindel: Steigern Sie Ihren CNC-Router mit automatischem Werkzeugwechsel

Eine Komponente, die die Fähigkeiten eines CNC-Fräsers erheblich verbessert, ist die ATC-Spindel (Automatic Tool Changer).