Китай най-големите CNC шпиндели на едро, предлагат всички видове cnc шпиндели за дърворезба, фрезоване на метал, каменна резба и т.н. Предложете шпиндел с по-високо качество с бърза доставка по целия свят.

Прецизен и ефикасен шпинделен двигател за CNC рутер за CNC машини

Надеждният шпиндел е сърцето на всеки CNC рутер, а правилният двигател на шпиндела на CNC рутер осигурява прецизност, издръжливост и плавна работа.

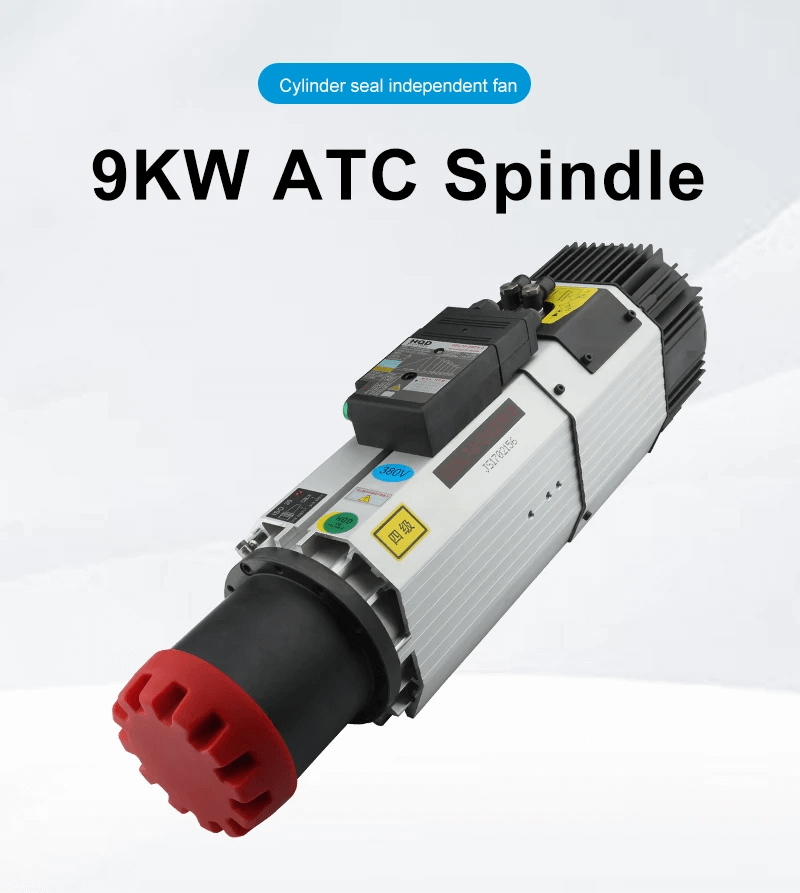

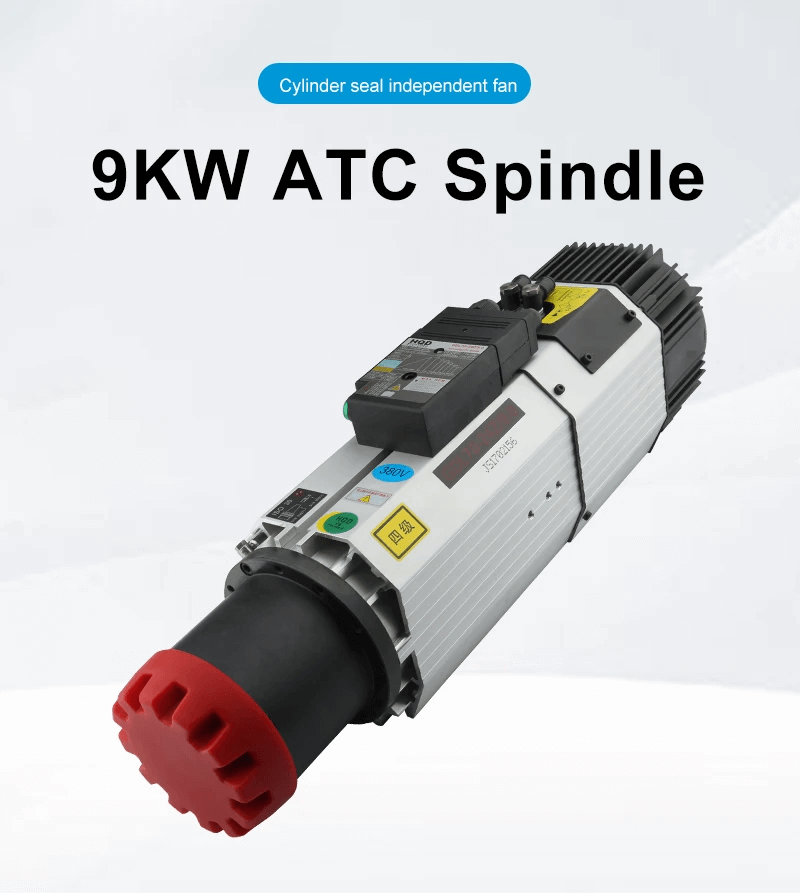

ATC шпинделен мотор 9 kW – Високопроизводителен шпиндел за CNC рутер

Надеждният шпиндел е сърцето на всеки CNC рутер, а серията шпинделни двигатели ATC HQD предлагат прецизност, издръжливост и високоскоростна производителност за дървообработване, металообработване и други промишлени приложения.

Шпинделни двигатели за пробиване: 9kW въздушно охлаждано високоскоростно решение

В света на CNC машинната обработка и металообработването, изборът на правилния шпинделен двигател е от решаващо значение за ефективността, точността и издръжливостта.

Шпинделни двигатели с въздушно охлаждане: 9kW високоскоростен шпинделен двигател за CNC рутер

При CNC обработката, шпинделният двигател е сърцето на машината. Той определя качеството, скоростта и прецизността на процеса на рязане.

BT30 шпинделен двигател, CNC шпинделен двигател за струг и ATC шпинделен двигател

В света на CNC обработката, шпинделният двигател е един от най-важните компоненти, който определя производителността, прецизността и надеждността на машината.

Шпиндел ATC за рутер: Подобрете вашия CNC рутер с автоматична смяна на инструменти

Един компонент, който драстично подобрява възможностите на CNC рутера, е шпинделът ATC (Автоматичен сменител на инструменти).