China biggest CNC Spindles Wholesale, Offer all kinds of cnc spindle for wood carving, metal milling, stone carving and so on. Offer higher quality spindle with Fast derlivery all over the worlds.

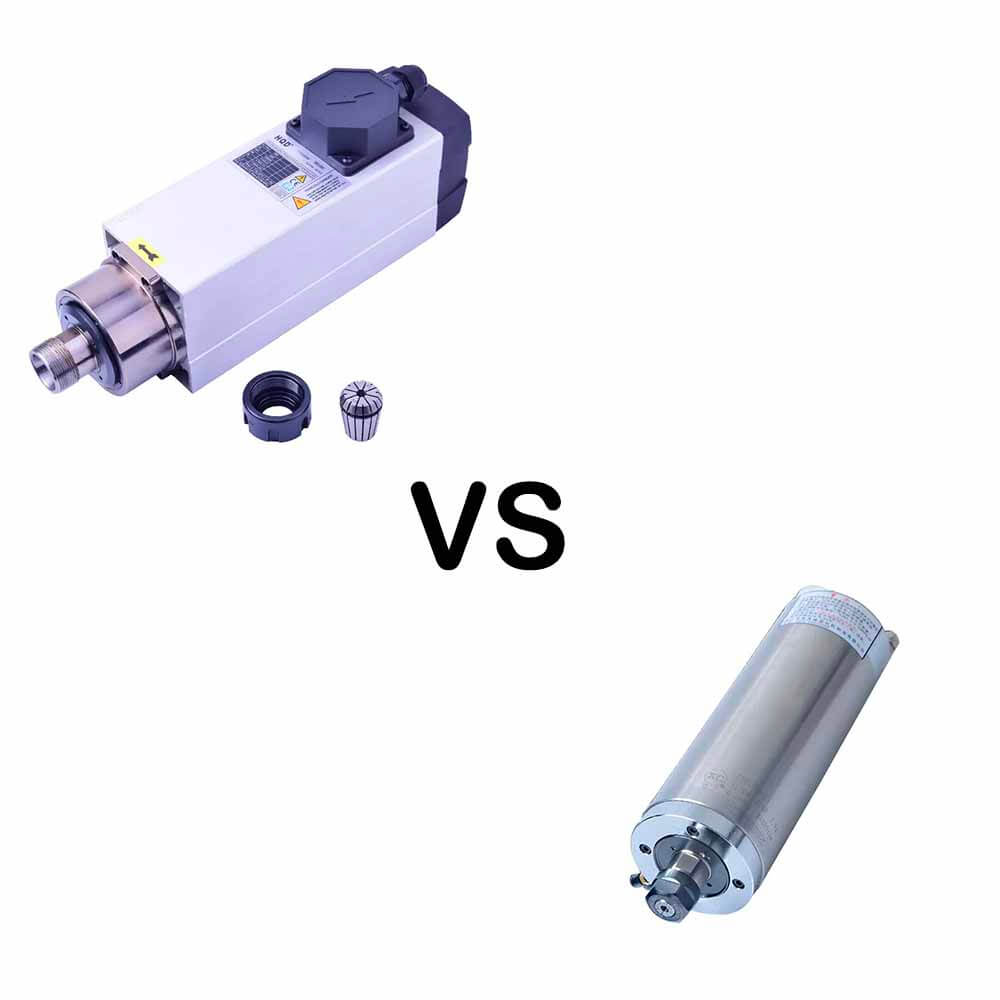

CNC Router Spindle Motor: Air Cooled vs Water Cooled

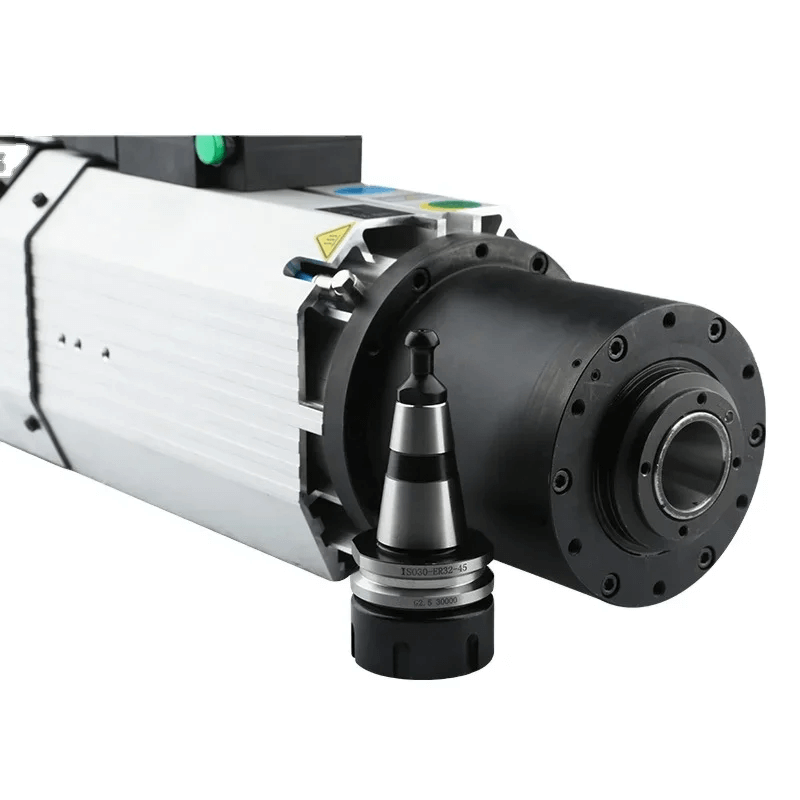

If you’re looking to upgrade your CNC machine for better performance, speed, and automation, investing in a CNC spindle with an automatic tool changer (ATC) is a game-changer.

Unlock Precision and Power with a High Torque 7.5kW ATC Spindle Motor

In modern CNC machining, the spindle motor plays a critical role in determining the performance, accuracy, and efficiency of a machine.

High-Performance 2.2kW Water-Cooled ATC Spindle JGL-80 2.2R30-20 for CNC Routers

For professionals and hobbyists alike, investing in a spindle motor ATC (Automatic Tool Changer) system can dramatically improve your workflow.

Discover the Right CNC ATC Spindle – From eBay to Colombo Precision

If you’re looking to upgrade your CNC machine for better performance, speed, and automation, investing in a CNC spindle with an automatic tool changer (ATC) is a game-changer.

Maximize CNC Efficiency with a 4kW ATC Spindle: Design, Cooling, and Performance

In today’s competitive CNC machining world, speed, accuracy, and automation are key to productivity.

Choosing the Right ATC Spindle for Your CNC Router: Hiteco, HSD, Jianken, and More

When upgrading your CNC router for higher efficiency and precision, selecting the right ATC spindle (Automatic Tool Change spindle) is crucial.