China biggest CNC Spindles Wholesale, Offer all kinds of cnc spindle for wood carving, metal milling, stone carving and so on. Offer higher quality spindle with Fast derlivery all over the worlds.

How to Choose the Best ATC Spindle for Your CNC Router: Affordable Options from China

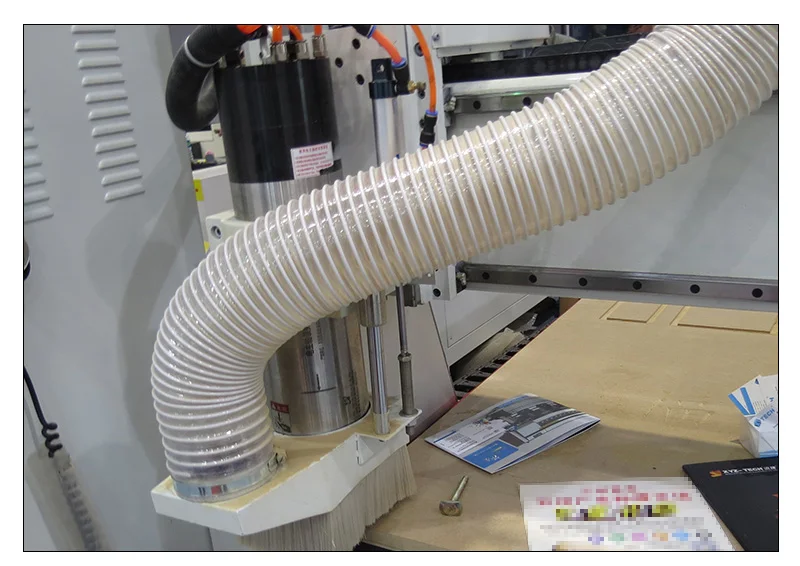

As CNC technology becomes more accessible, more businesses and hobbyists are upgrading their machines with an ATC spindle—a powerful tool that automates tool changes and improves workflow speed.

Bring Automation to Your Workshop: DIY ATC Spindle Solutions for CNC Routers

As the demand for precision and automation grows, even hobbyists and small workshop owners are embracing the power of ATC spindle motors.

Maximize CNC Performance with ATC Router Spindle and Conversion Solutions

Looking to improve the productivity of your CNC router or upgrade from a manual spindle setup?

Compact Power for Precision Machining: 2.2kW ATC Spindle for CNC Routers

In the CNC world, not every application needs a massive spindle.

Upgrade Your CNC Router with a Compact 1.5kW ATC Spindle (110V Available)

In the evolving world of CNC machining, precision, speed, and automation are key to success—whether you’re running a small workshop, prototyping lab, or custom furniture business.

Boost CNC Efficiency with BT30 ATC Spindle for Precision Machining

In the fast-moving CNC manufacturing world, automation and precision are key to staying competitive. One component that plays a vital role in modern CNC routers is the ATC spindle.