Common Problems Associated with Air-Cooled Spindles and How to Address Them

Air-cooled spindles are popular in CNC machines for their simplicity and efficiency, but they can encounter various issues that affect performance. Understanding these problems and how to address them is crucial for maintaining optimal spindle function and extending its lifespan. This article outlines common issues with air-cooled spindles and provides solutions for each, emphasizing the importance of regular maintenance and inspection.

Table of Contents

Overheating

Problem: The spindle overheats during operation.

Solution: Ensure the cooling system (fan) is working properly, clean the cooling fins regularly, and optimize cutting parameters to minimize heat generation.

Inadequate Cooling

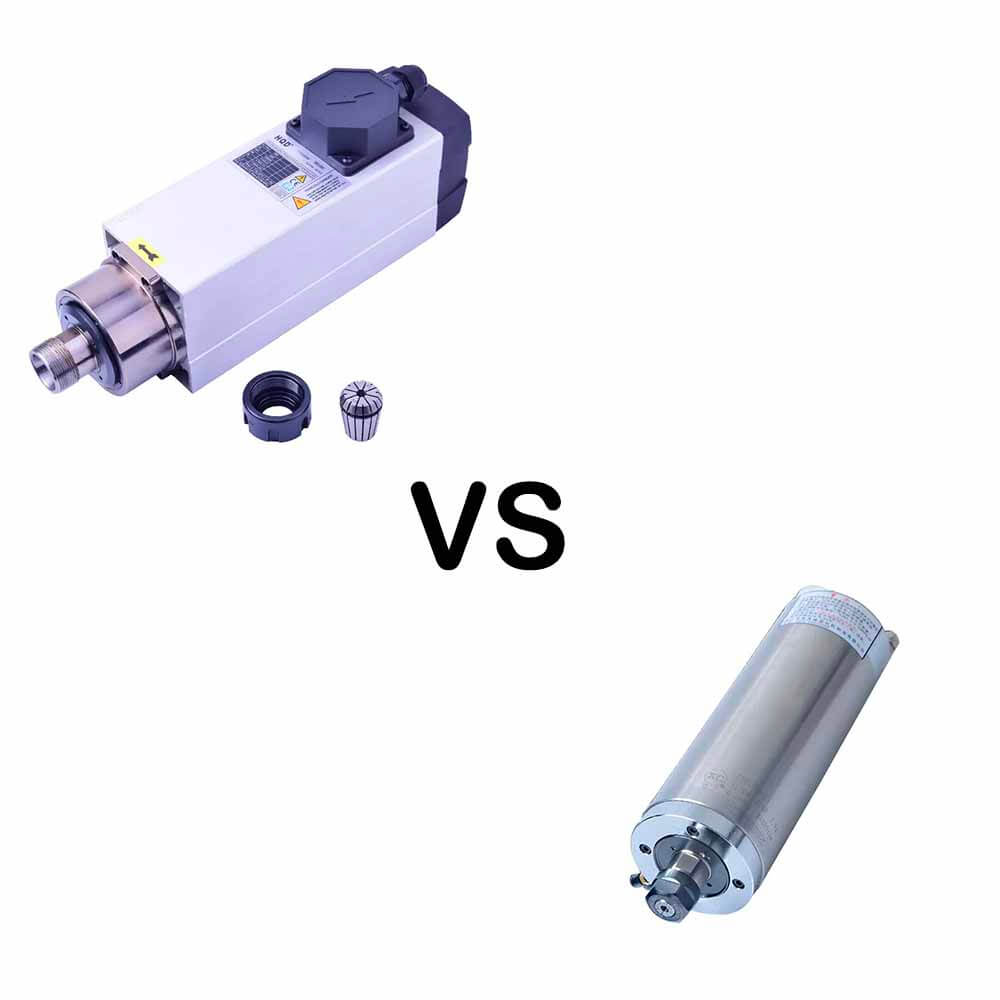

Water-Cooled Spindles: Best suited for warmer areas. They offer superior cooling, and for enhanced performance, a chiller can be added to maintain low water temperatures. Despite concerns, water-cooled spindles will not wet your materials, as the cooling process is internal and self-contained.

For example, popular air-cooled spindles include the Italian HSD and the domestically produced Hanqi (HQD), while Changsheng is a well-known brand for water-cooled spindles.

Power Considerations for Spindles

Problem: Insufficient cooling reduces spindle performance.

Solution: Ensure consistent airflow over the spindle, inspect hoses and connections for blockages or leaks, and improve overall workspace ventilation.

Vibration or Unusual Noises

Problem: The spindle produces vibrations or unusual sounds during use.

Solution: Balance the spindle and tool assembly, check bearings for wear or damage, and ensure all parts such as clamps and tool holders are secure.

Inconsistent Speed or Power

Problem: The spindle speed or power output fluctuates.

Solution: Confirm a stable power supply, inspect wiring for damage, and verify the correct spindle speed and power settings in the CNC controller.

Spindle Runout

Problem: Excessive radial or axial movement of the spindle.

Solution: Inspect the collet and tool holder, measure runout with a dial indicator, and check the spindle taper for damage. Adjust or replace components as necessary.

Frequent Tool Changes

Problem: Tool changes occur more often than expected.

Solution: Review CNC program settings for tool changes and inspect the tool changer mechanism for smooth operation. Lubricate or repair as needed.

Dust and Debris Accumulation

Problem: Dust and debris build-up affects spindle performance.

Solution: Regularly clean the spindle and cooling system, and consider using an air purge system to keep critical components free from dust.

Addressing and Preventing Issues

To ensure the optimal performance and longevity of air-cooled spindles in CNC machines, it is essential to regularly inspect and maintain the cooling system. Balance the spindle and tool assembly to prevent vibrations, and check and replace bearings, collets, and tool holders as needed. Additionally, ensure a stable power supply and proper wiring for consistent spindle performance.

Conclusion

Regular maintenance and proactive inspection are key to preventing common problems with air-cooled spindles. By addressing issues such as overheating, inadequate cooling, vibrations, inconsistent speed, spindle runout, frequent tool changes, and dust accumulation, operators can maintain optimal spindle performance and extend the lifespan of their CNC machines.

Comments

The CNC Spindles

Recent Blogs

Why Choose Us

Inquiry Us

TAGS

China biggest CNC Spindles Wholesale, Offer all kinds of cnc spindle for wood carving, metal milling, stone carving and so on. Offer higher quality spindle with Fast derlivery all over the worlds.

CNC Router Spindle Motor: Air Cooled vs Water Cooled

If you’re looking to upgrade your CNC machine for better performance, speed, and automation, investing in a CNC spindle with an automatic tool changer (ATC) is a game-changer.

Unlock Precision and Power with a High Torque 7.5kW ATC Spindle Motor

In modern CNC machining, the spindle motor plays a critical role in determining the performance, accuracy, and efficiency of a machine.

High-Performance 2.2kW Water-Cooled ATC Spindle JGL-80 2.2R30-20 for CNC Routers

For professionals and hobbyists alike, investing in a spindle motor ATC (Automatic Tool Changer) system can dramatically improve your workflow.

Discover the Right CNC ATC Spindle – From eBay to Colombo Precision

If you’re looking to upgrade your CNC machine for better performance, speed, and automation, investing in a CNC spindle with an automatic tool changer (ATC) is a game-changer.

Maximize CNC Efficiency with a 4kW ATC Spindle: Design, Cooling, and Performance

In today’s competitive CNC machining world, speed, accuracy, and automation are key to productivity.

Choosing the Right ATC Spindle for Your CNC Router: Hiteco, HSD, Jianken, and More

When upgrading your CNC router for higher efficiency and precision, selecting the right ATC spindle (Automatic Tool Change spindle) is crucial.