How to Choose the Right Engraving Machine CNC Spindles

Therefore, selecting the appropriate spindle is vital for achieving optimal results. To make an informed decision, it’s essential to understand the spindle’s performance and classification.

Table of Contents

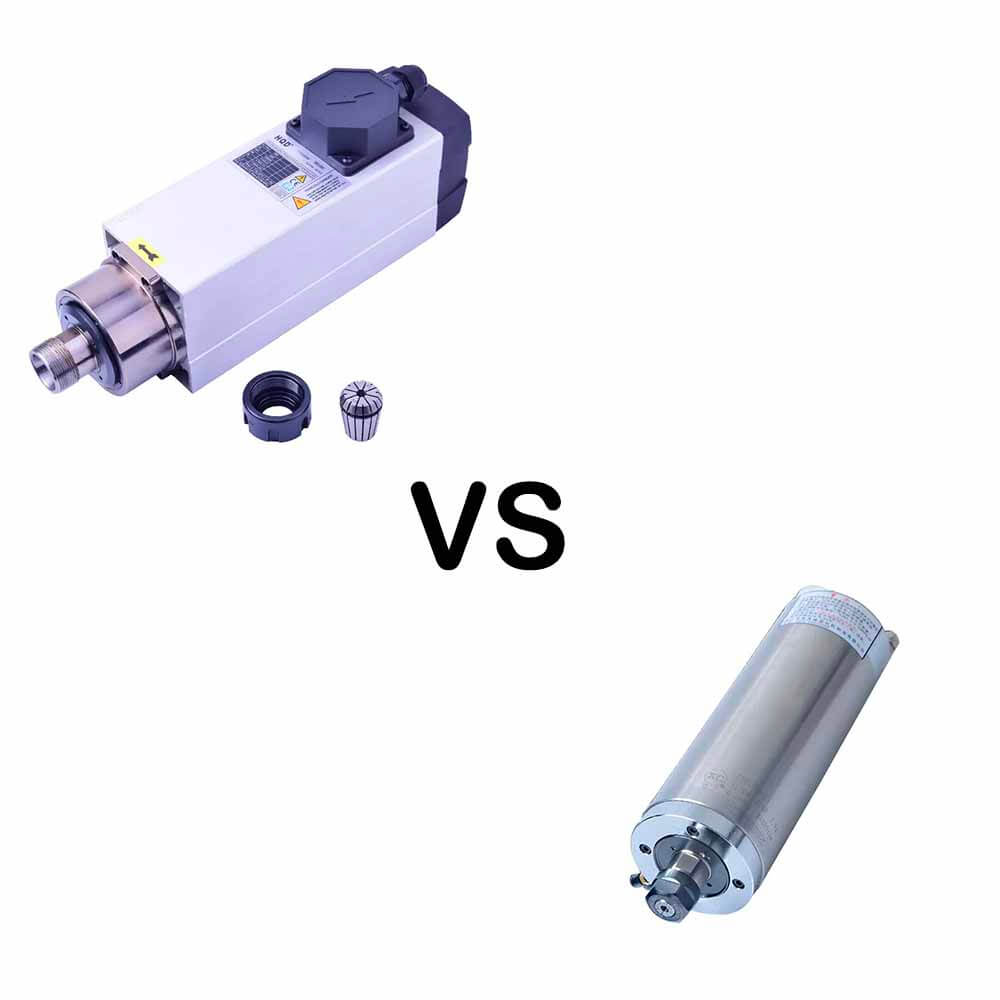

Spindle Classification and Cooling Methods

Engraving machine spindles are primarily categorized into air-cooled and water-cooled types. The choice between these depends largely on your local climate:

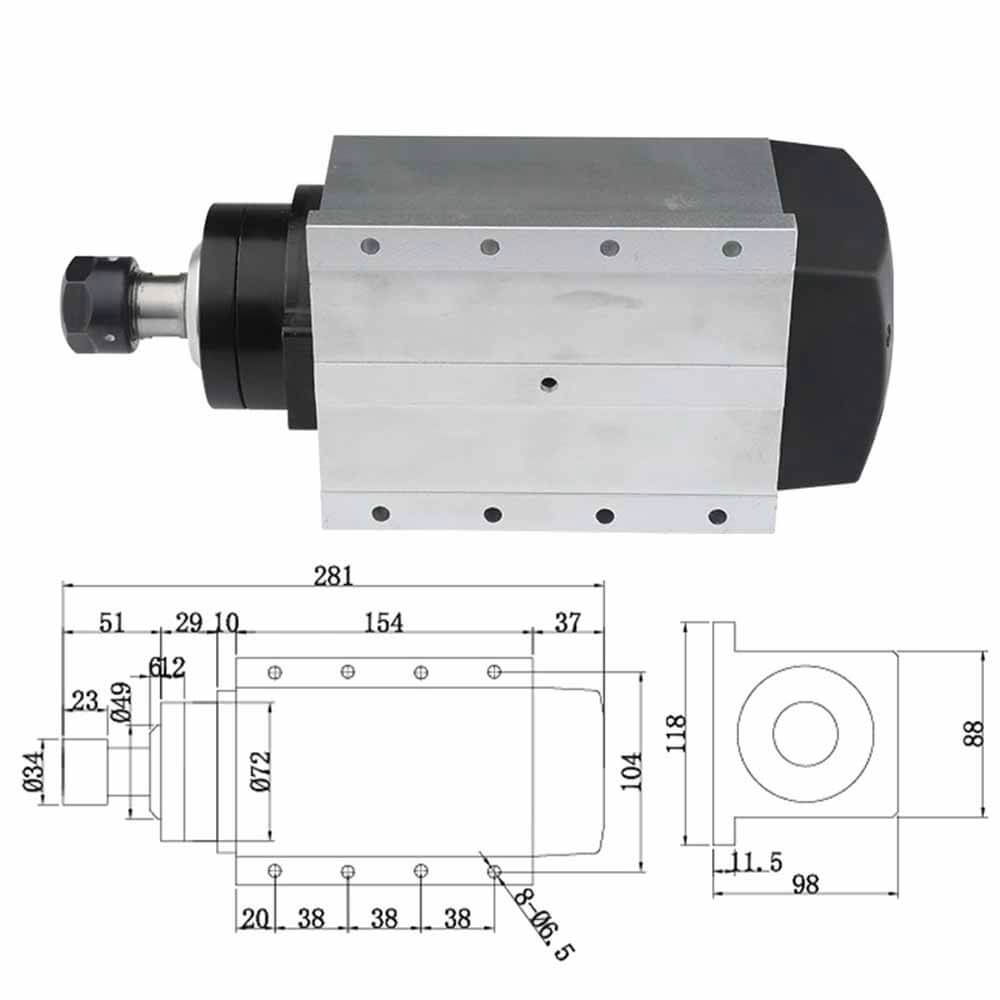

Air-Cooled Spindles: Ideal for colder climates, providing effective cooling without the need for additional equipment.

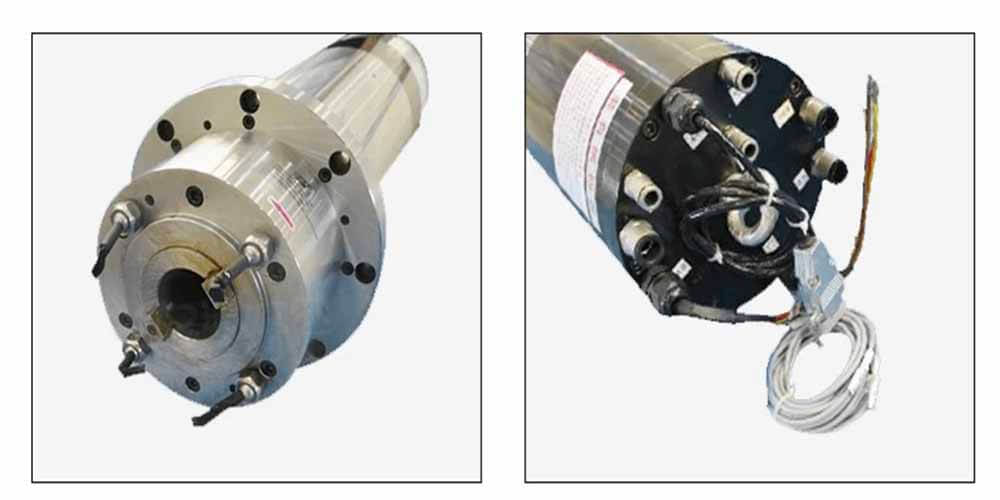

Water-Cooled Spindles: Best suited for warmer areas. They offer superior cooling, and for enhanced performance, a chiller can be added to maintain low water temperatures. Despite concerns, water-cooled spindles will not wet your materials, as the cooling process is internal and self-contained.

For example, popular air-cooled spindles include the Italian HSD and the domestically produced Hanqi (HQD), while Changsheng is a well-known brand for water-cooled spindles.

Power Considerations for Spindles

Spindles vary in power, with low-power options such as 1.5KW, 2.2KW, and 3.5KW commonly used in smaller advertising engraving machines (e.g., 6090, 6012, 1212 models). The 3.5KW spindles can also be used in standard woodworking engraving machines like the 1325 and 1530 models.

For high processing efficiency, especially when working with solid wood materials, a spindle motor with more than 2.2KW is recommended.

Manual vs. Automatic Tool-Changing Spindles

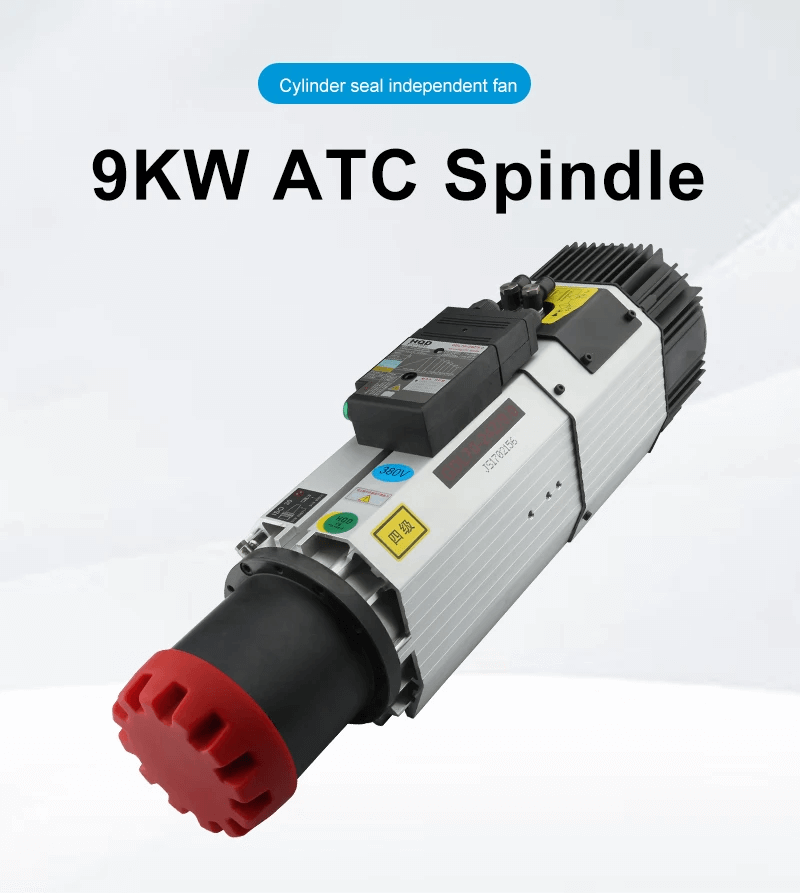

Standard spindles for manual tool-changing engraving machines come in various configurations based on the equipment’s specifications. However, for automated processes, an Automatic Tool Change (ATC) spindle is necessary. ATC spindles include domestic air-cooled models at 9.0KW and Italian HSD 9.0KW, as well as domestic water-cooled ATC spindles at 2.2KW and 5.5KW. For instance, the 1325C2 Standard Version is equipped with a 9.0KW HQD ATC air-cooled spindle.

Conclusion

Choosing the right spindle for your engraving machine involves understanding its cooling method, power requirements, and whether you need a manual or automatic tool-changing system. If you have specific processing needs or further questions, feel free to reach out. Our team will be happy to recommend the best configuration for your requirements.

Comments

By optimizing energy consumption through temperature regulation, the ATC system promotes environmental sustainability. It reduces power usage and lowers carbon emissions, contributing to a greener wood carving process.

Conclusion

The ATC Spindle 12KW has revolutionized wood carving with its powerful motor, automatic tool change feature, and air-cooling system. This tool boosts efficiency, precision, and creativity, setting a new standard in the art of wood carving.

TAGS

China biggest CNC Spindles Wholesale, Offer all kinds of cnc spindle for wood carving, metal milling, stone carving and so on. Offer higher quality spindle with Fast derlivery all over the worlds.

High-Performance 24000rpm Spindle Motor | ATC CNC Spindle for Woodworking

In the modern woodworking industry, speed, precision, and efficiency define success.

Reliable Air Cooled Spindle Motor Supplier | Factory Price & Maintenance Guide

Air cooled spindle motors are widely used in CNC routers, engraving machines, milling systems, and automated production lines.

How Does an ATC Spindle Work?

A critical component that contributes to both is the ATC spindle, short for Automatic Tool Changer spindle.

CNC Router Spindle Motor: Air Cooled vs Water Cooled

If you’re looking to upgrade your CNC machine for better performance, speed, and automation, investing in a CNC spindle with an automatic tool changer (ATC) is a game-changer.

Unlock Precision and Power with a High Torque 7.5kW ATC Spindle Motor

In modern CNC machining, the spindle motor plays a critical role in determining the performance, accuracy, and efficiency of a machine.

High-Performance 2.2kW Water-Cooled ATC Spindle JGL-80 2.2R30-20 for CNC Routers

For professionals and hobbyists alike, investing in a spindle motor ATC (Automatic Tool Changer) system can dramatically improve your workflow.