High-Performance 24000rpm Spindle Motor | ATC CNC Spindle for Woodworking

In the modern woodworking industry, speed, precision, and efficiency define success.

Reliable Air Cooled Spindle Motor Supplier | Factory Price & Maintenance Guide

Air cooled spindle motors are widely used in CNC routers, engraving machines, milling systems, and automated production lines.

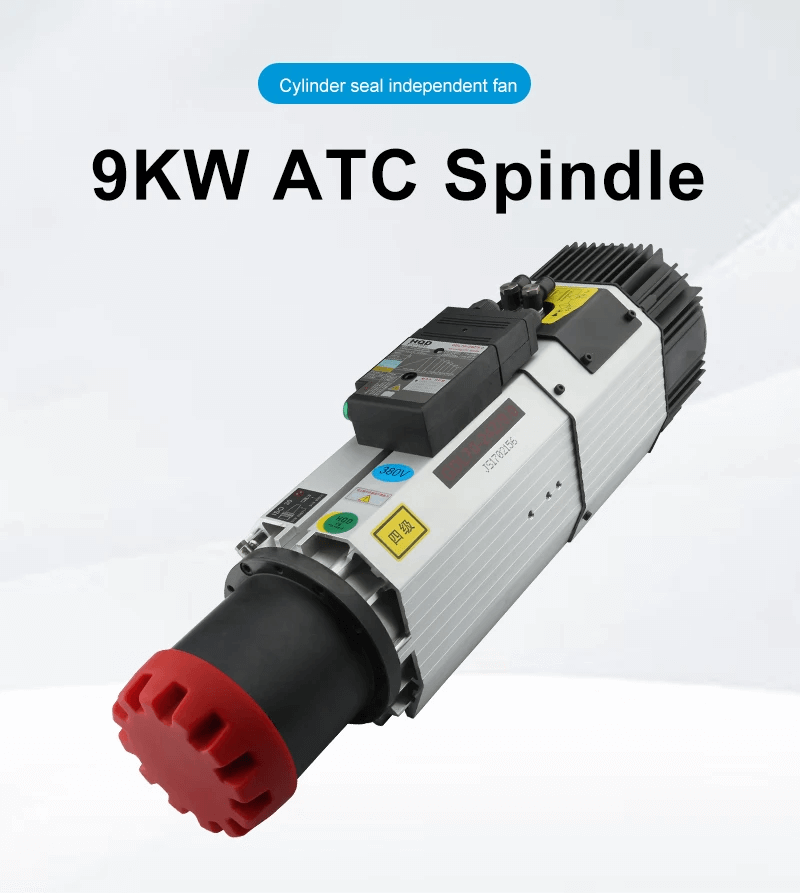

How Does an ATC Spindle Work?

A critical component that contributes to both is the ATC spindle, short for Automatic Tool Changer spindle.

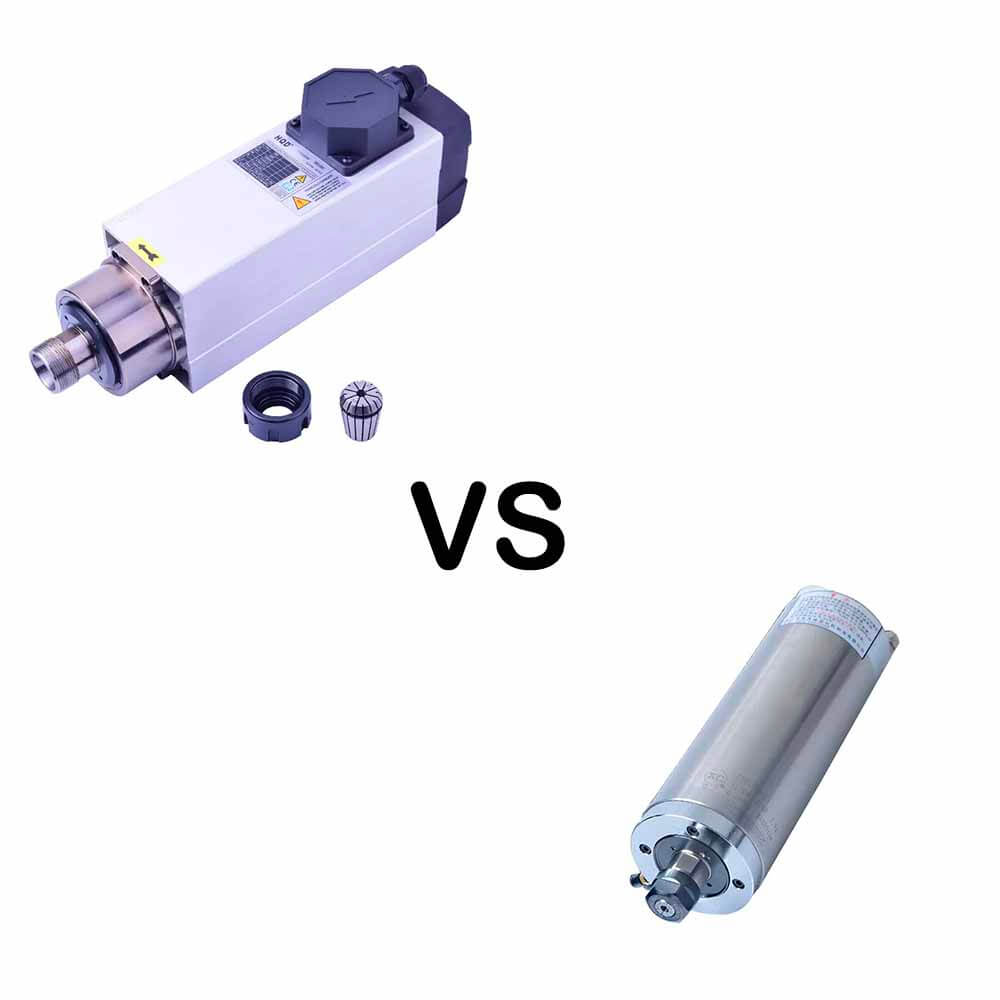

CNC Router Spindle Motor: Air Cooled vs Water Cooled

If you’re looking to upgrade your CNC machine for better performance, speed, and automation, investing in a CNC spindle with an automatic tool changer (ATC) is a game-changer.

Unlock Precision and Power with a High Torque 7.5kW ATC Spindle Motor

In modern CNC machining, the spindle motor plays a critical role in determining the performance, accuracy, and efficiency of a machine.

High-Performance 2.2kW Water-Cooled ATC Spindle JGL-80 2.2R30-20 for CNC Routers

For professionals and hobbyists alike, investing in a spindle motor ATC (Automatic Tool Changer) system can dramatically improve your workflow.