7.5kw Water Cooling Spindle Motor Metal Mould Stone Carving

Description

7.5kW Water Cooling Spindle Motor Metal Mould Stone Carving

7.5kw Water Cooling Spindle Motor Metal Mould Stone Carving

When it comes to precision machining and carving, the 7.5kW water cooling spindle motor is a game-changer. This advanced spindle motor is designed to meet the rigorous demands of metal mould making and stone carving. In this article, we will explore the features, parameters, applications, materials, and industry areas where this spindle motor excels.

Features of 7.5kw Water Cooling Spindle Motor Metal Mould Stone Carving

The 7.5kW water cooling spindle motor offers numerous features that make it ideal for both metal mould making and stone carving:

- High Power Output: With a robust 7.5kW output, this spindle motor can handle heavy-duty cutting and carving tasks with ease.

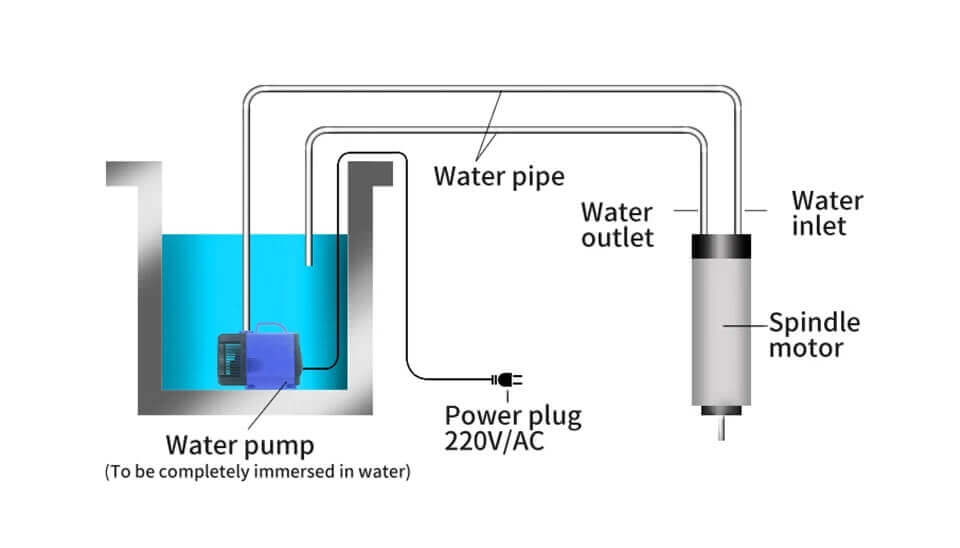

- Water Cooling System: The integrated water cooling system ensures optimal operating temperatures, reducing wear and extending the motor’s lifespan.

- Precision and Stability: High-speed bearings and a balanced rotor provide exceptional precision and stability during operation.

- Versatile Compatibility: Suitable for various CNC machines and routers, enhancing its versatility in different applications.

- Durability: Constructed with high-quality materials to withstand the harsh conditions of metal and stone machining.

Parameters of 7.5kw Water Cooling Spindle Motor Metal Mould Stone Carving

Understanding the technical parameters of the 7.5kW water cooling spindle motor is crucial for selecting the right motor for your needs:

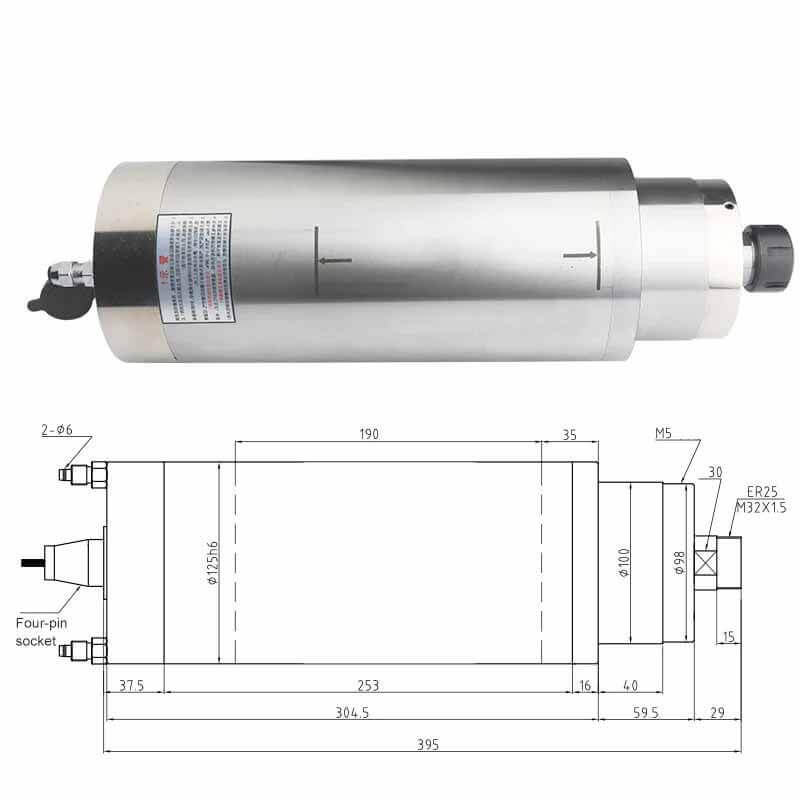

- Model: GDK125-18-24Z / 7.5kw

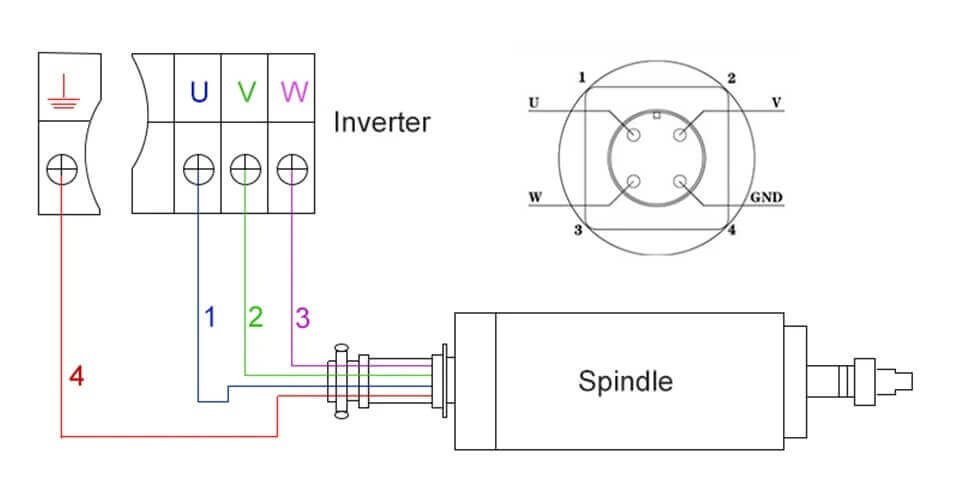

- Speed regulation mode: The three-phase output inverter can change the spindle speed by changing the frequency of the inverter.

- Cooling method: water cooling

- Power interface: optional 4-pin waterproof air plug. The air plugs marked “1”, “2”, “3”, “4”, “1”, “2”, “3” have been connected to the inverter (U, V, W), and 4 has been connected to The inverter equipment is grounded.

- Power: 7.5kw

- Voltage: 380V

- Current: 16A/28A

- Frequency: 300-400Hz

- Speed: 18000-24000rpm

- Cone hole: 2UM

- Diameter (mm): 125

- 4 fully sealed angular contact ceramic bearings

- Chuck: ER25

- Clamping tool diameter: 13mm, 12.7mm, 12mm, 11mm, 10mm, 9mm, 8mm, 7mm, 6.5mm, 6.35mm, 6mm, 5.5mm, 5mm, 4.5mm, 4mm, 3.5mm, 3.175mm, 3mm, 2.5mm , 2mm, 1.5mm, 1mm (standard 6mm)

- Water-cooled ER25 chuck

- Grease lubrication

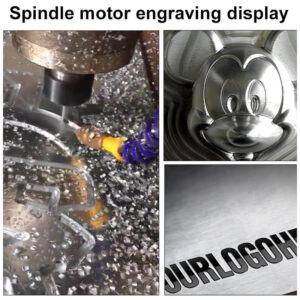

- Main use: Carving wood, bamboo, ordinary PCB, PVC, PMMA, plastic, two-color board (ABS) and other non-metals, and can also be carved on soft metal surfaces such as gold, silver, copper, aluminum, Pb, etc.

Applications of the 7.5kw Water Cooling Spindle Motor Metal Mould Stone Carving

This powerful spindle motor is designed for a range of applications, making it an essential tool in various industries:

Metal Mould Making

In the field of metal mould making, precision and power are paramount. The 7.5kW water cooling spindle motor excels in:

- High Precision Cutting: Achieving intricate designs and fine details in metal moulds.

- Heavy-Duty Machining: Capable of handling tough materials such as steel and aluminum.

- Consistency: Delivering consistent performance for large production runs.

Stone Carving

Stone carving requires a motor that can handle the hardness of the material while maintaining precision:

- Smooth Operation: The water cooling system ensures the motor operates smoothly without overheating.

- Detailed Carvings: Perfect for creating detailed sculptures and engravings in stone.

- Versatility: Suitable for various types of stone, including granite, marble, and limestone.

Materials Suitable for the 7.5kW Water Cooling Spindle Motor

The 7.5kW water cooling spindle motor is versatile and can handle a variety of materials:

- Metals: Including steel, aluminum, copper, and brass.

- Stones: Such as granite, marble, limestone, and sandstone.

- Composites: Including high-strength composites used in aerospace and automotive industries.

- Plastics: For precision machining in plastic mould making.

Industry Areas Utilizing the 7.5kw Water Cooling Spindle Motor Metal Mould Stone Carving

Several industries benefit from the capabilities of the 7.5kW water cooling spindle motor:

Automotive Industry

- Engine Components: Precision machining of metal parts.

- Mould Making: Creating moulds for plastic and metal components.

Aerospace Industry

- High-Precision Parts: Machining of aerospace-grade metals and composites.

- Tooling: Production of high-quality moulds and tools.

Stone Carving Industry

- Architectural Elements: Carving detailed architectural features.

- Monuments and Art: Creating intricate stone sculptures and monuments.

Manufacturing Industry

- Mould Making: For plastic injection moulding and metal casting.

- Custom Parts: Production of custom parts for various machinery.

Conclusion of 7.5kw Water Cooling Spindle Motor Metal Mould Stone Carving

the 7.5kW water cooling spindle motor is a versatile and powerful tool essential for metal mould making and stone carving. Its high power output, precision, and durability make it suitable for a wide range of materials and applications, supporting various industries in achieving high-quality machining results. Whether you are involved in the automotive, aerospace, stone carving, or general manufacturing industry, this spindle motor can significantly enhance your production capabilities.